Underbridge work platform system

A work platform and pin shaft technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of large construction hanging baskets, large safety hazards, and expensive bridge inspection vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

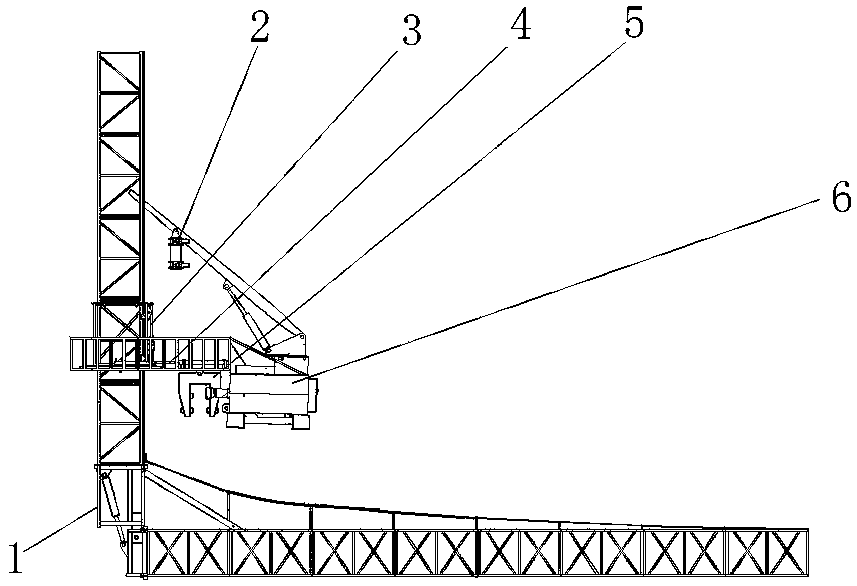

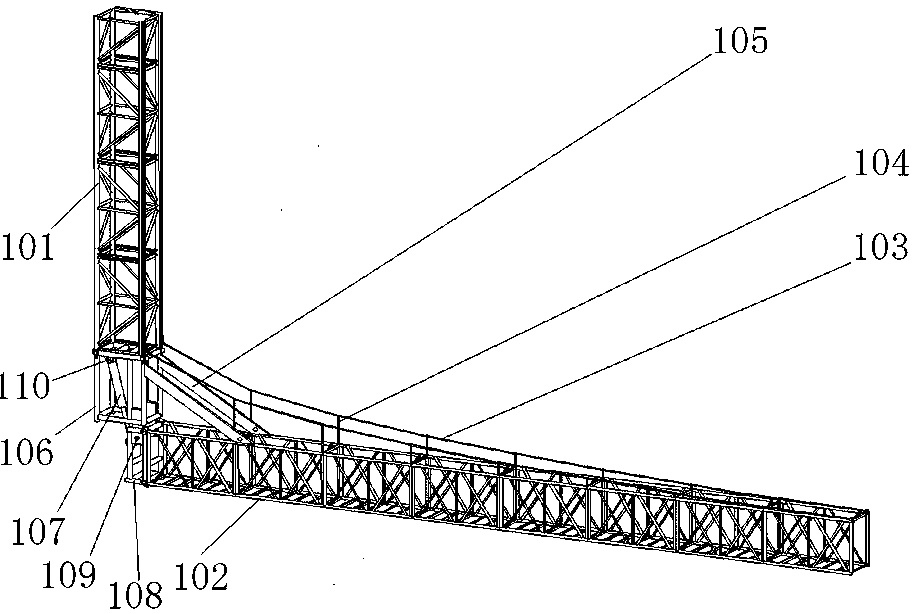

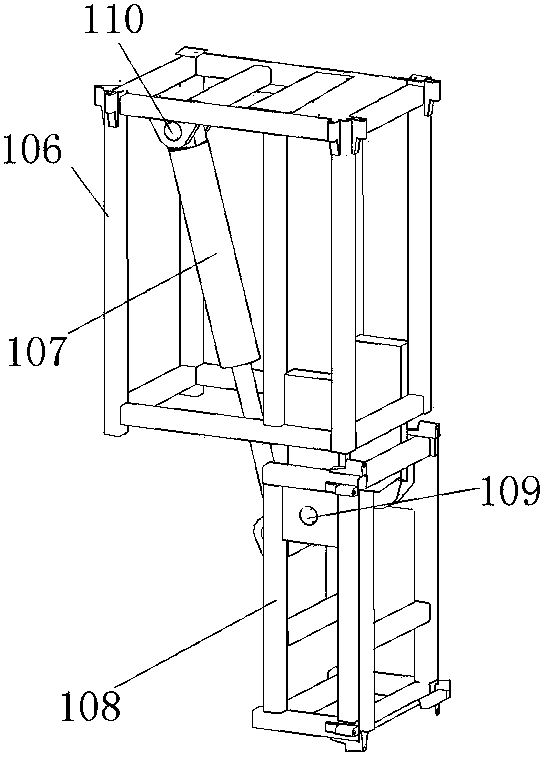

[0052]An under-bridge operating platform system of the present invention is composed of a folding arm anti-flex tension mechanism 1, an obstacle passing mechanism 2, a lifting mechanism 3, a rotating mechanism 4, an anti-tipping device 5, and a walking mechanism 6, and is characterized in that; The upper end of the arm anti-flex tension mechanism 1 is inserted into the rotating mechanism 4, and the lifting mechanism 3 is installed on the rotating mechanism 4. There is an obstacle mechanism 2, wherein; the folding arm anti-flex tension mechanism 1 is composed of a support frame 101, an operation platform 102, a steel wire rope 103, a pull rod 104, a support rod 105, an upper frame 106, a push cylinder A107, a lower frame 108, a pin Shaft A109, pin shaft B110, pin shaft C111 are composed, the lower end of the support frame 101 is fixedly connected to one end of the upper frame 106, the other end of the lower frame 108 is hinged to the left end of the work platform 102, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com