Fixed-micropyle boring and milling conical surface bottom die

A technology of boring, milling and taper, which is applied in the field of tools for processing fixed bead rings, and can solve problems such as difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

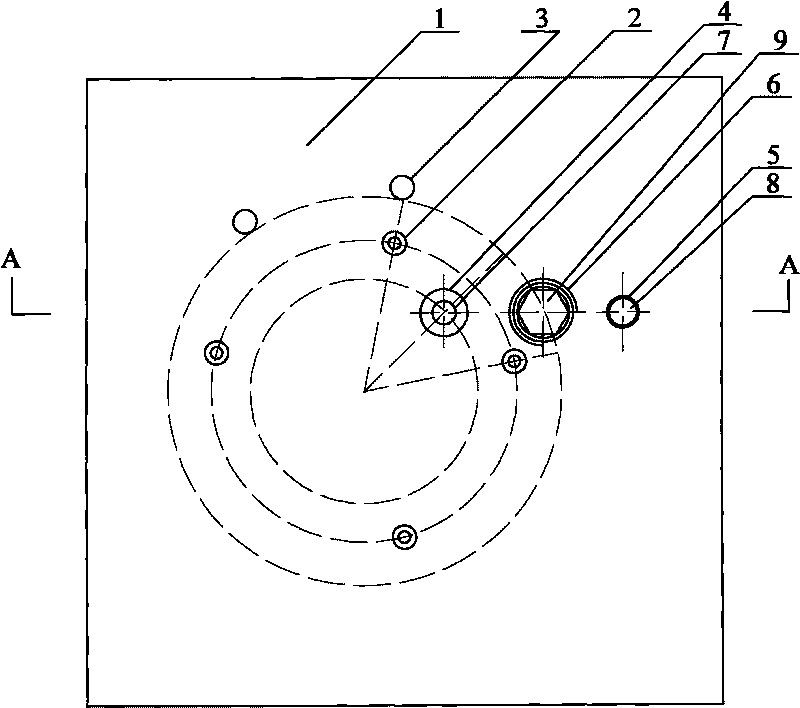

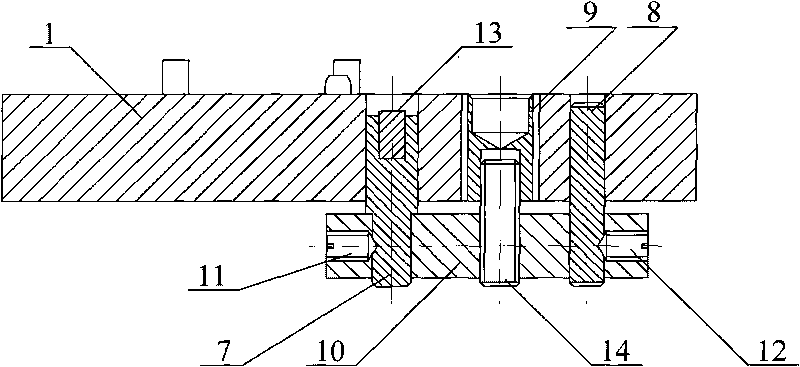

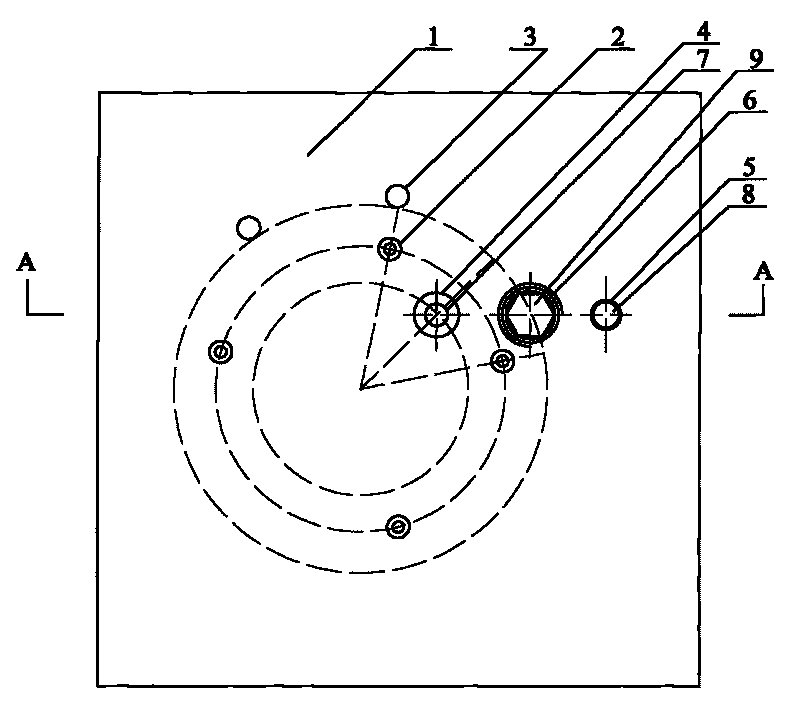

[0017] Such as figure 1 with figure 2 As shown, the bottom mold in this embodiment includes a bottom plate 1 , and four support points 2 of equal height are connected on the upper side of the bottom plate 1 . Preferably, the above four support points 2 are on the same circumference. In addition, two positioning points 3 on the same circumference are connected on the upper side of the base plate 1 . The circles where the four supporting points 2 are located are concentric with the circles where the two positioning points 3 are located, and the two positioning points 3 are located on the periphery of the four supporting points 2 .

[0018] A first slide pin connection through hole 4 , a second slide pin connection through hole 5 and a threaded through hole 6 are provided on the bottom plate 1 . The first sliding pin 7 and the second sliding pin 8 are slidably connected in the first sliding pin connecting through hole 4 and the second sliding pin connecting through hole 5 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com