Temperature sensor detector

A temperature sensor and detection device technology, applied in the field of metallurgy, can solve the problems of inability to identify the temperature sensor, inability to detect the accuracy and response rate of the temperature sensor, and affect the normal operation of the casting machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

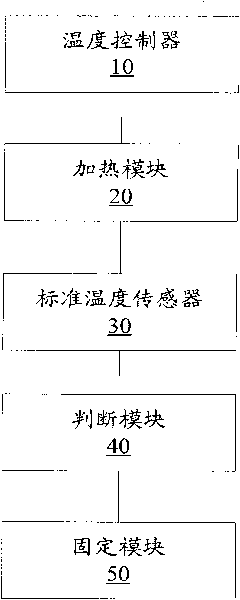

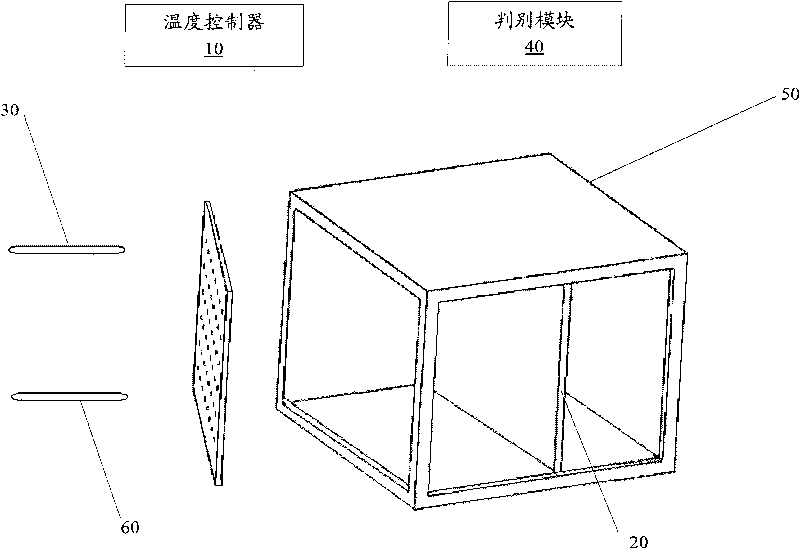

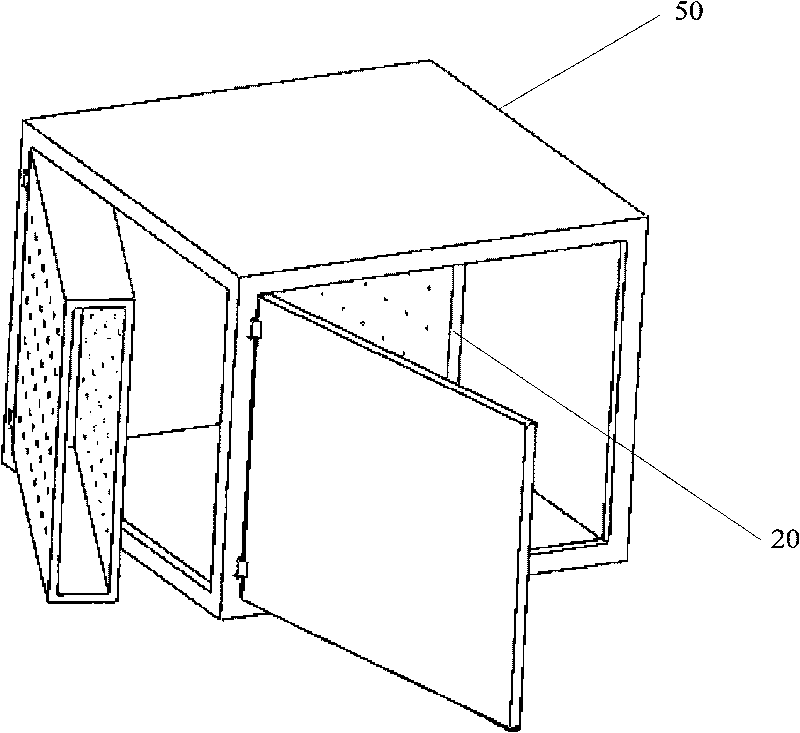

[0016] figure 1 It shows a schematic diagram of an explosion of a temperature sensor detection device according to an embodiment of the present invention, including: a temperature controller 10, a heating module 20, a standard temperature sensor 30, a discrimination module 40 and a fixing module 50, wherein

[0017] Fixed module 50, used for fixing standard temperature sensor 30;

[0018] The standard temperature sensor 30 and the temperature sensor 60 to be tested are used to sense the temperature of the heating module 20;

[0019] The temperature controller 10 is used to control the heating module 20 to heat up or cool down according to the set temperature;

[0020] The judging module 40 is electrically connected to the standard temperature sensor 50 and the temperature sensor to be tested 60 , and is used to compare the standard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com