Nut

A technology for nuts and outer rings, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of falling off, loose nuts, easy to scratch the surface of objects, etc. The effect of preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

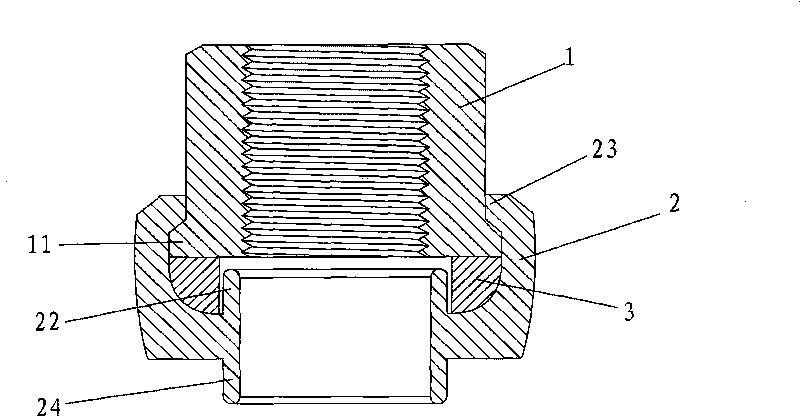

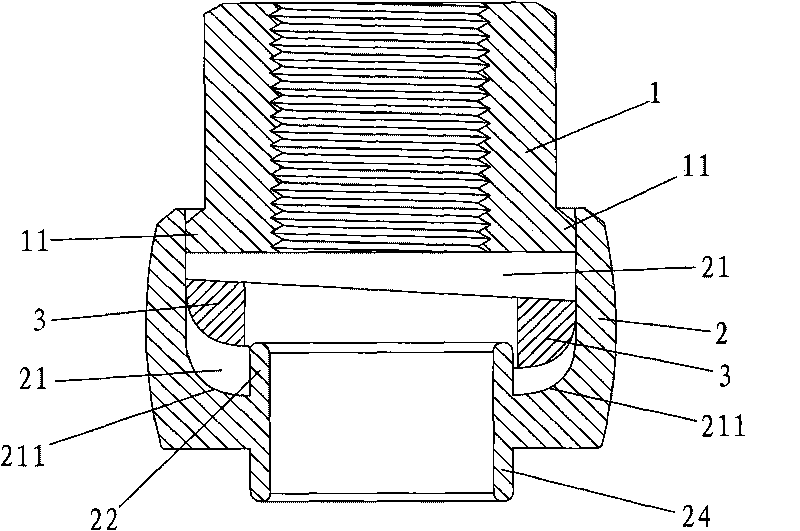

[0016] A kind of nut of the present invention, the embodiment is as follows figure 1 , 2 As shown, it includes a nut 1, an outer ring 2 and a spring washer 3. The outer edge of one axial end of the nut 1 is provided with a convex ring 11, and the corresponding end of the outer ring 2 is sleeved outside the convex ring 11. In the accommodating groove 21 of the spring washer 3, the ends of the corresponding ends of the outer ring 2 are riveted inward to form a limit ring 23, so that the convex ring 11 is restricted from moving in the accommodating groove 21, which can prevent the nut 1 from separating from the outer ring 2 . The spring washer 3 is arranged in the accommodating groove 21 and passes through the screw rod of the bolt assembly. The inner wall of the accommodating groove 21 at the other axial end of the outer ring 2 is provided with an end face corresponding to the corresponding end of the spring washer 3 . The matching fitting surface 211, the end face of one end ...

Embodiment 2

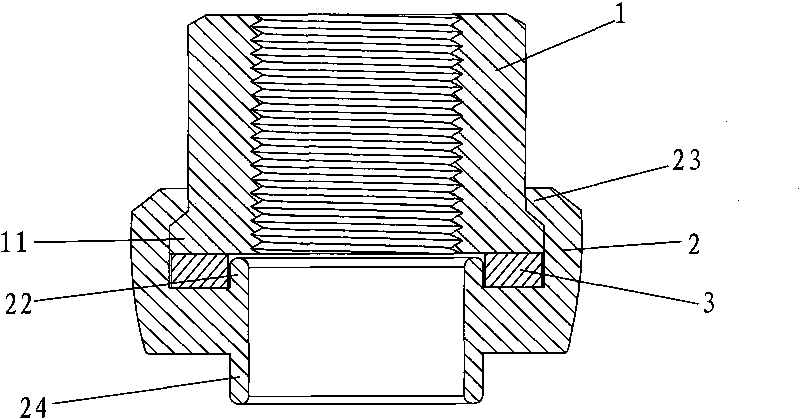

[0019] A nut of the present invention, such as image 3 , 4 As shown, the difference between the second embodiment and the first embodiment is only that: the inner wall of the accommodating groove 21 located at the other axial end of the outer ring 2 is provided with a fitting surface 212 which is adapted to the end face of the corresponding end of the spring washer 3 , the fitting surface 212 is a plane, and the end face of one end of the spring washer 3 that fits with the fitting surface 212 is a plane that matches the fitting surface 212 .

[0020] The nut of the present invention can be applied to different fields such as machinery, electric power, automobile, railway, aviation and the like. In the present invention, the hollow cylindrical sheath 22 can also have an extension portion 24 extending from the other axial end of the outer ring 2, so that when the nut is used on a tire nut, the extension portion 24 can be inserted into the tire screw and the tire steel ring. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com