Rotation-preventing cutting sleeve

A ferrule and anti-rotation technology, which is applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, passing components, etc., can solve problems such as leakage, ferrule and steel pipe rotation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

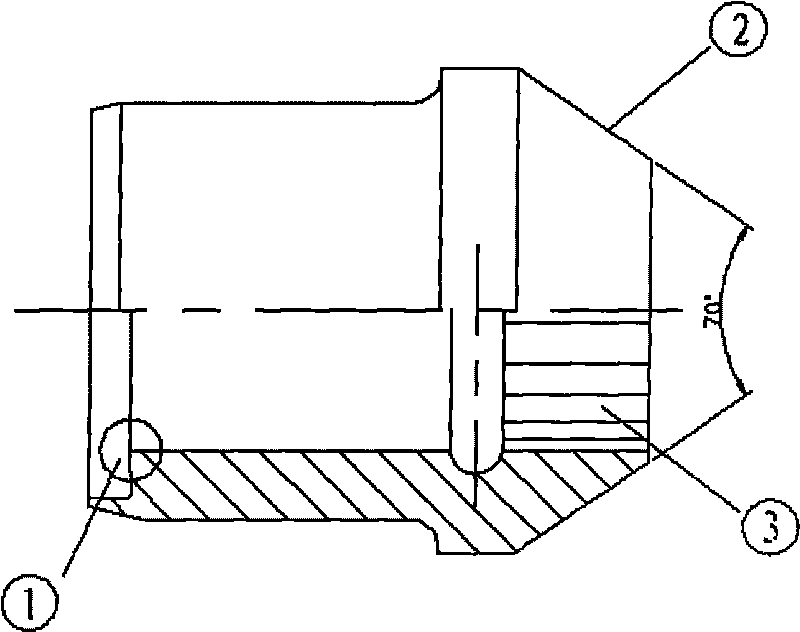

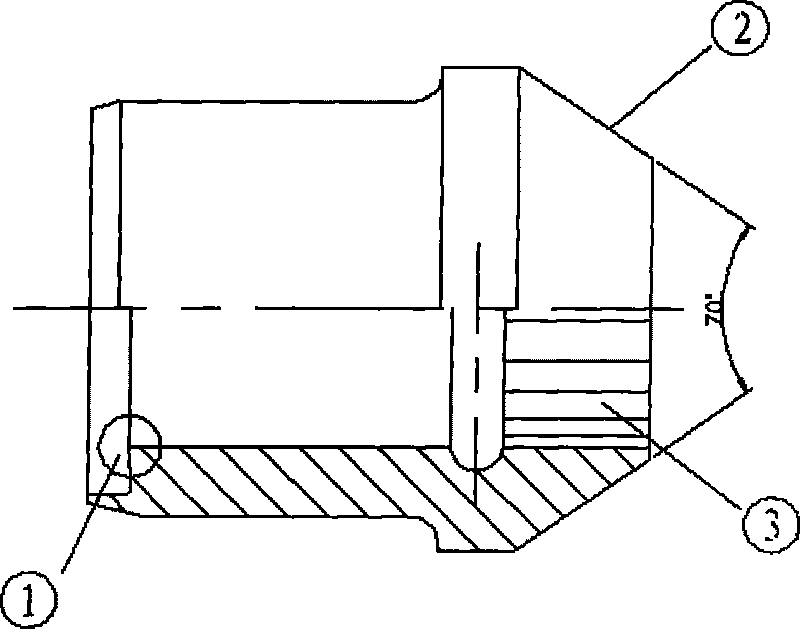

[0010] exist figure 1 In the schematic diagram of the structure, the function of the ferrule cutting edge (1) is to embed the steel pipe when under pressure to play a sealing role. The angle of the cone surface (2) at the end of the ferrule is made to be 70 to 74 degrees, which is convenient for the cone surface of the ferrule to deform more easily when it is gradually squeezed by the rotation of the nut and the joint, so that the tooth-shaped internal spline (3) is embedded in the steel pipe, play a blocking role.

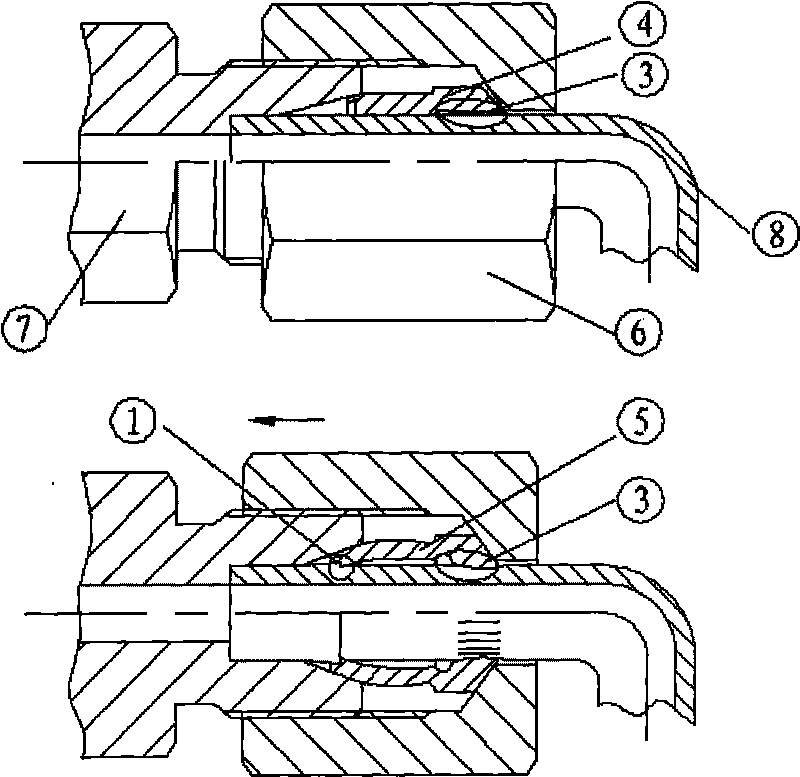

[0011] exist figure 2 In the schematic diagram of the implementation of the installation, the state of the ferrule is obviously different before and after the completion of the installation. When the nut (6) cooperates with the male thread on the outside of the joint body (7) interface, the cutting edge (1) of the ferrule is pressed and embedded The steel pipe (8) deforms the ferrule (5) and forms a surface contact seal with the inner tapered surface of the joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com