High voltage bushing on-line monitoring ground wire lead-out structure

A high-voltage bushing and lead-out structure technology, applied in the field of nuclear power, can solve the problem of inability to install bushing grounding current measuring elements, etc., and achieve the effects of ensuring electrical connection and sealing performance, good electrical connection and sealing performance, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

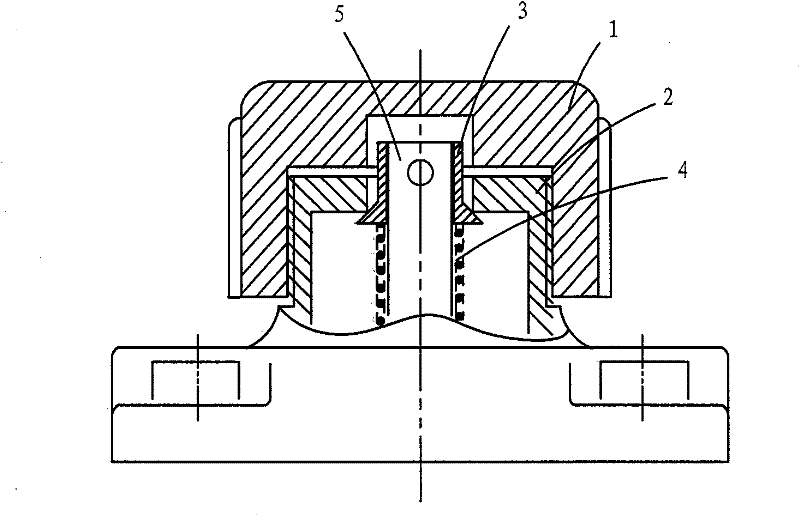

[0031] See figure 1 , the existing high-voltage bushing end screen structure of the main transformer includes a high-voltage bushing 2 and a terminal 5, the terminal 5 can be a cylindrical or flat pin-shaped structure, the lower end is fixed on the bushing 2, and the upper end passes through the high-voltage bushing 2 The center hole protrudes outward, and there is a copper column 3 with a tapered end on the upper end. A spring 4 is arranged under the copper column 3, which is placed on the lower end of the terminal 5. A cap 1 is screwed on the sleeve 7. Through the cap 1 The cover can isolate the terminal 5 from the outside world.

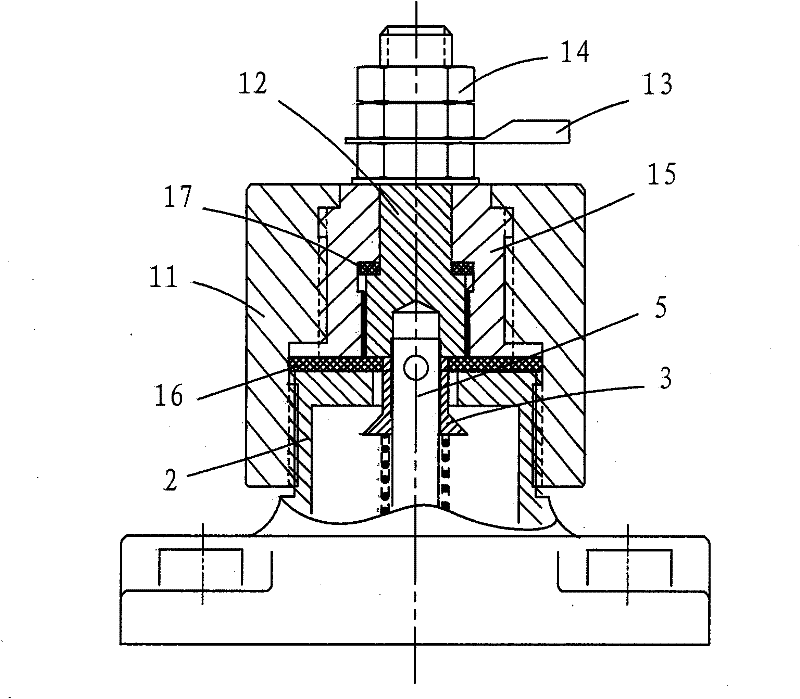

[0032] see figure 2 According to the above-mentioned existing final screen structure, an outer casing 11 is designed to replace the above-mentioned cap 1. The outer casing 11 contains a hollow cavity, and the hollow cavity structure can be gradually reduced in diameter from bottom to top. Small stepped inner cylindrical structure (the cavity in...

Embodiment 2

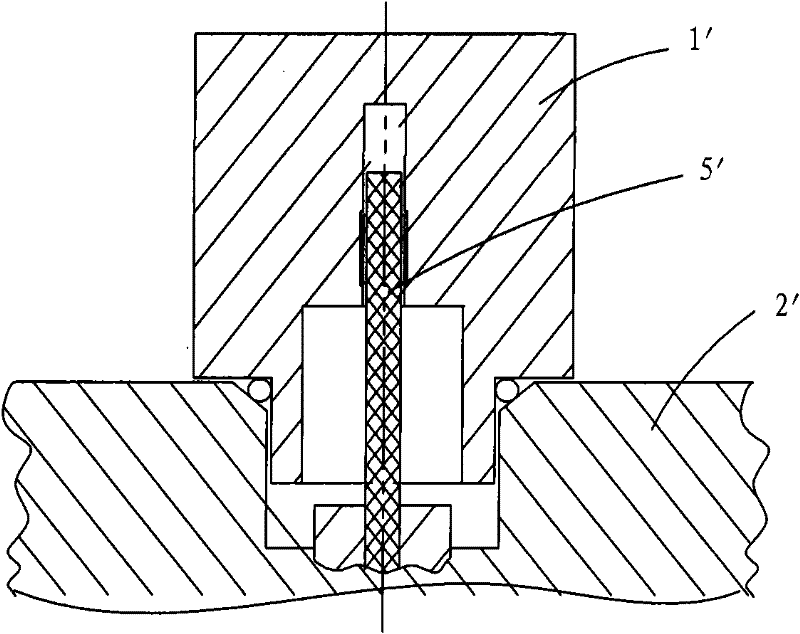

[0039] See image 3 , another existing main transformer high-voltage bushing end screen structure includes a high-voltage bushing 2' and a terminal 5'. The terminal 5' can be a cylindrical or flat pin-shaped structure, and the lower end is fixed on the high-voltage bushing 2 ', the terminal 5' can be isolated from the outside world through the cover of the cap 1'.

[0040] see Figure 4 According to the above-mentioned existing final screen structure, the second embodiment of the present invention designs a jacket 21 to replace the above-mentioned cap 1'. The diameter size should match the size of the inner hole of the high-voltage bushing 2', and its outer surface is processed with external threads, which can be spirally connected with the high-voltage bushing 2'; in the hollow cavity of the jacket 21, a conductive rod 22 is also arranged, placed in the jacket In the upper part of the cavity in 21, one end (bottom) of the conductive rod 22 is provided with a central hole, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com