Sectional hydraulic pin puller

A pin puller and hydraulic technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of bulky mechanism, high labor intensity, low efficiency, etc., improve the efficiency of disassembly and installation, reduce labor intensity, and be convenient to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

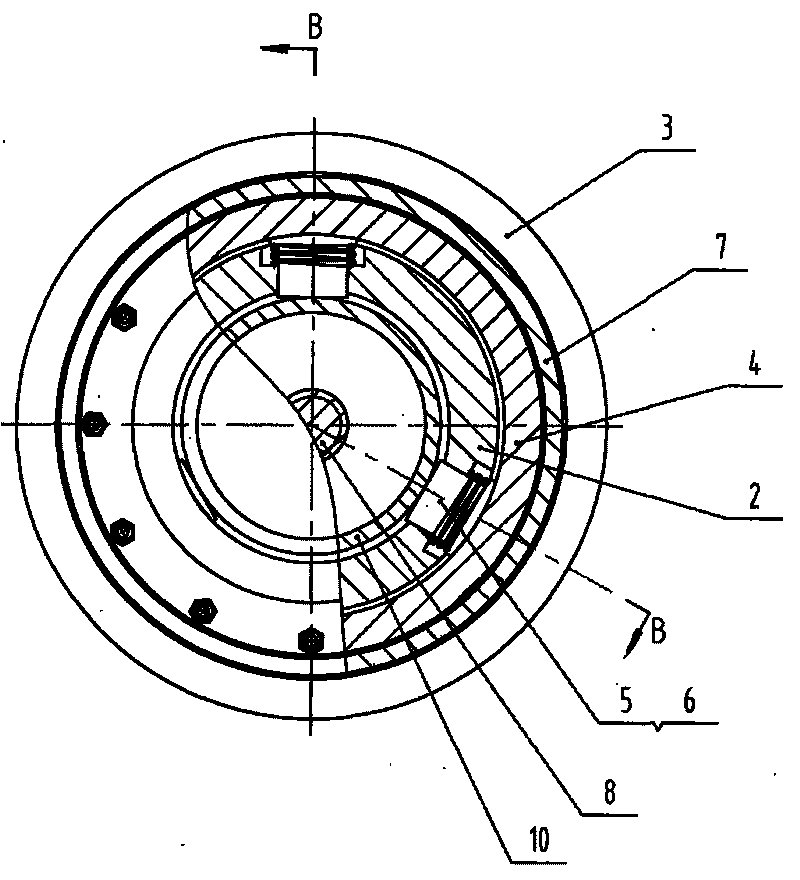

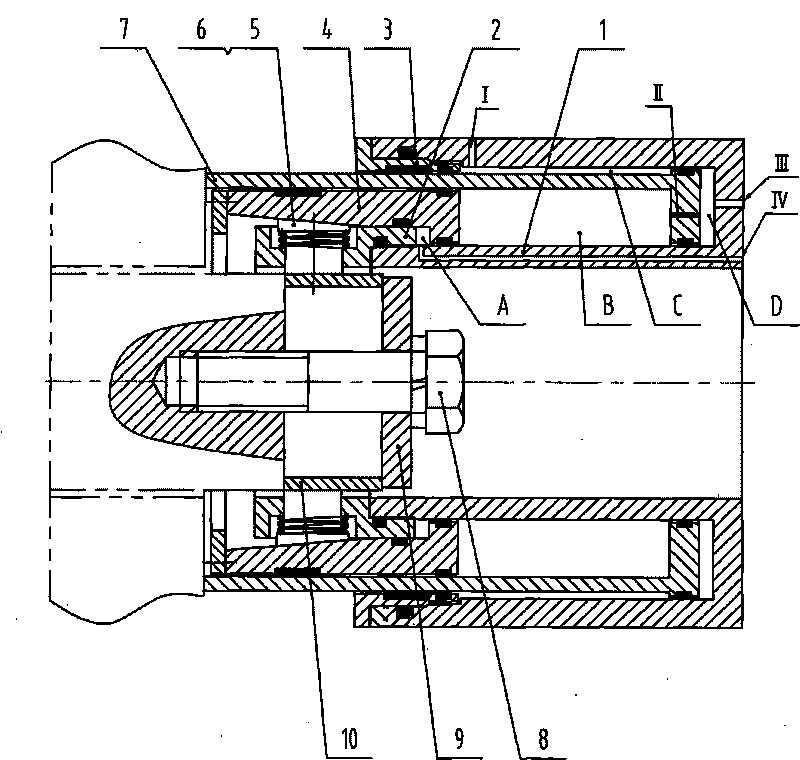

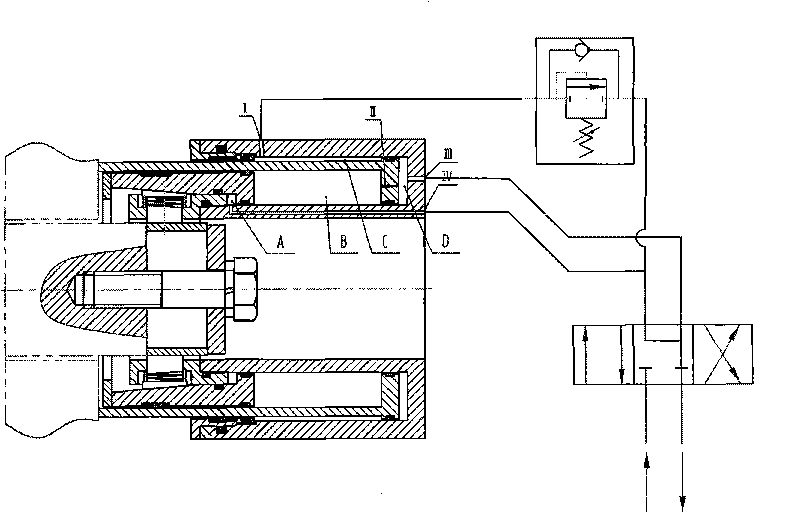

[0014] This segmented hydraulic pin puller includes a cylinder body and a hydraulic chamber arranged on the cylinder body. The cylinder body includes an outer cylinder body 1 and an inner cylinder body 7. The outer cylinder body 1 is a coaxial annular outer sleeve and the inner sleeve is formed from the rear End plates are connected. The inner cylinder body 7 is coaxial with the outer cylinder body 1 and is also annular with a rear end plate. The rear portion of the inner cylinder body 7 is located between the outer casing and the inner casing of the outer cylinder body 1 . A wedging mechanism is arranged between the inner cylinder body 7 and the inner sleeve of the outer cylinder body 1 . Described wedging mechanism comprises guide sleeve 2, ferrule 4 and block 5, and the rear end of guide sleeve 2 is fixedly connected with the front end of outer cylinder body 1 inner sleeve by thread, and ferrule 4 is arranged on inner cylinder body 7 and guide sleeve 2, the outer diameter ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap