Valve train for internal combustion engine

A technology of valve mechanism and internal combustion engine, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc. It can solve the problems of inaccurate flushness between the concave part and the conversion pin, so as to avoid clamping and deformation, avoid shear stress, and short response the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

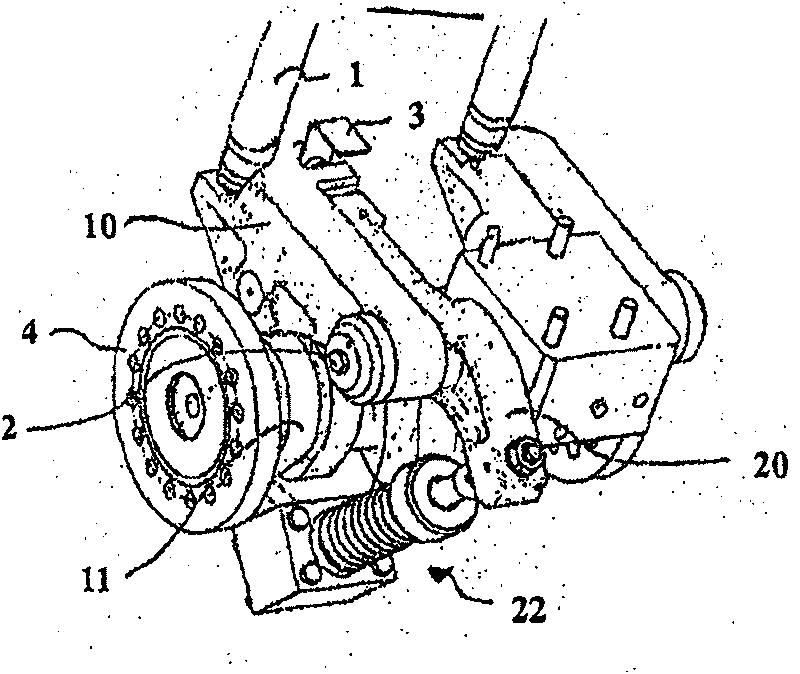

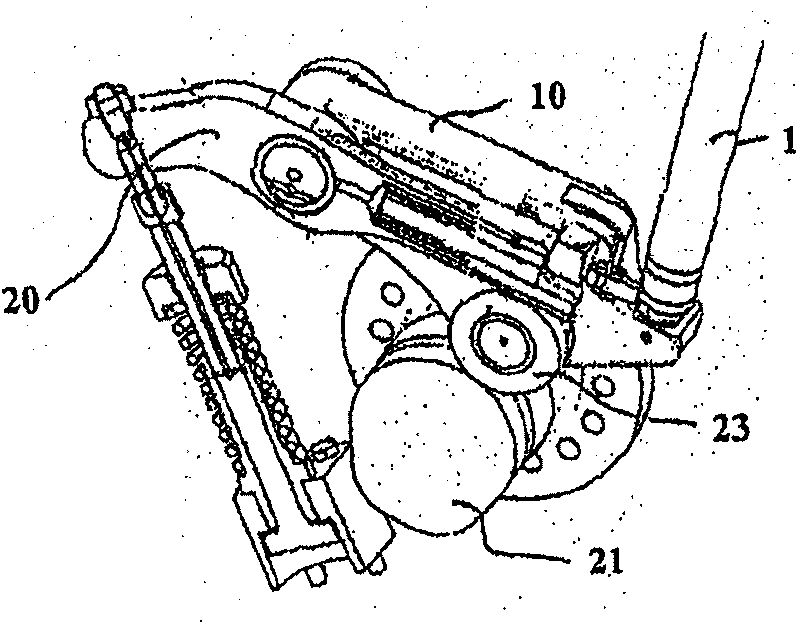

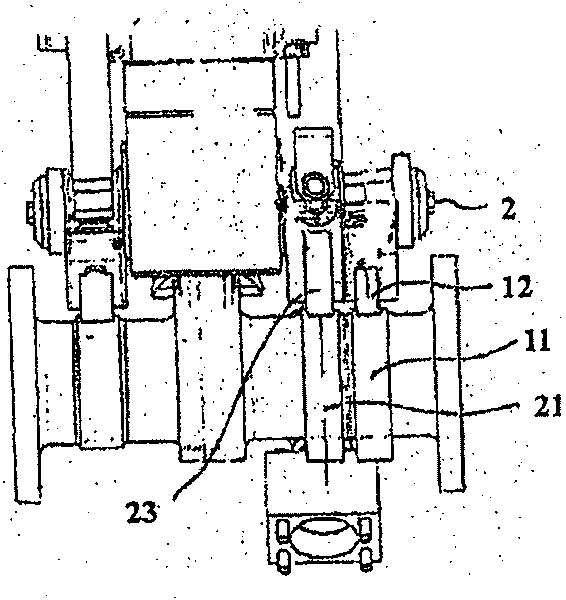

[0053] figure 1 A valve train according to an embodiment of the invention is shown in a perspective view. It comprises a main rocker 10 for actuating a valve lifter 1 and a switching rocker 20 adjacent thereto. The main rocker and switching rocker are mounted rotatably about the lever axis 2, wherein the main rocker 10 is counter to the direction of rotation D by the valve springs acting on the valve lifters 1 in a manner not shown in detail ( Figure 4 ) is preloaded. In the same way, the switching rocker 20 is prestressed against the direction of rotation D by means of a second return element 22 comprising a compression spring, so that both rockers 10 , 20 are prestressed against the camshaft 4 .

[0054] Here, the main rocker 10 utilizes rollers 12 ( image 3 ) is pressed against the first cam 11 of the camshaft 4 on which the roller 12 rolls, while the switching rocker 20 is pressed against the second cam 21 of such a camshaft 4 with the roller 23 in a corresponding man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com