Method for designing and drawing directional drilling trace under coal mine

A trajectory design and directional drilling technology, applied in the field of trajectory map drawing, can solve the problems of single storage format, inability to import the trajectory map into the electronic version of the geological plan, and great difficulty. It achieves various storage formats, facilitates data exchange and sharing, and calculates Accurate and fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

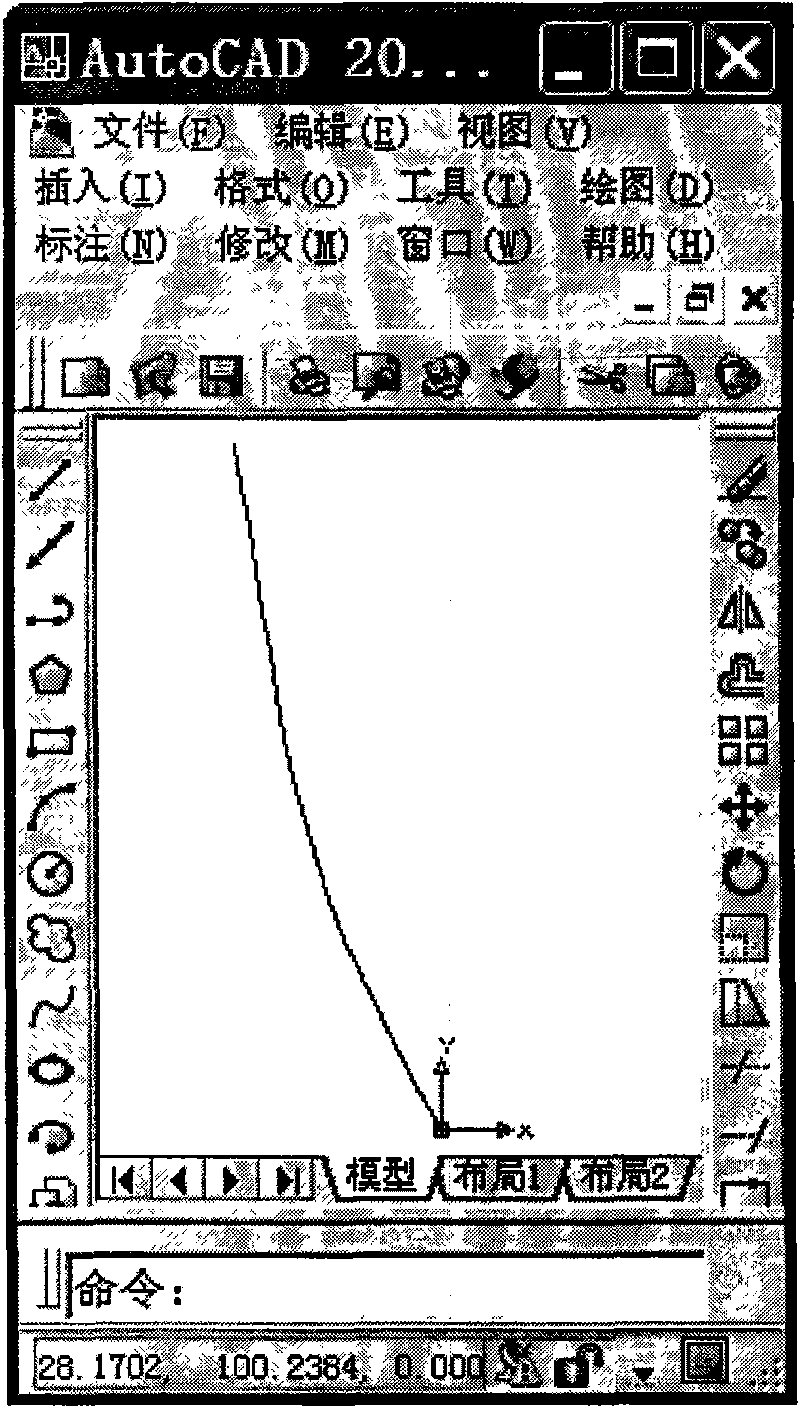

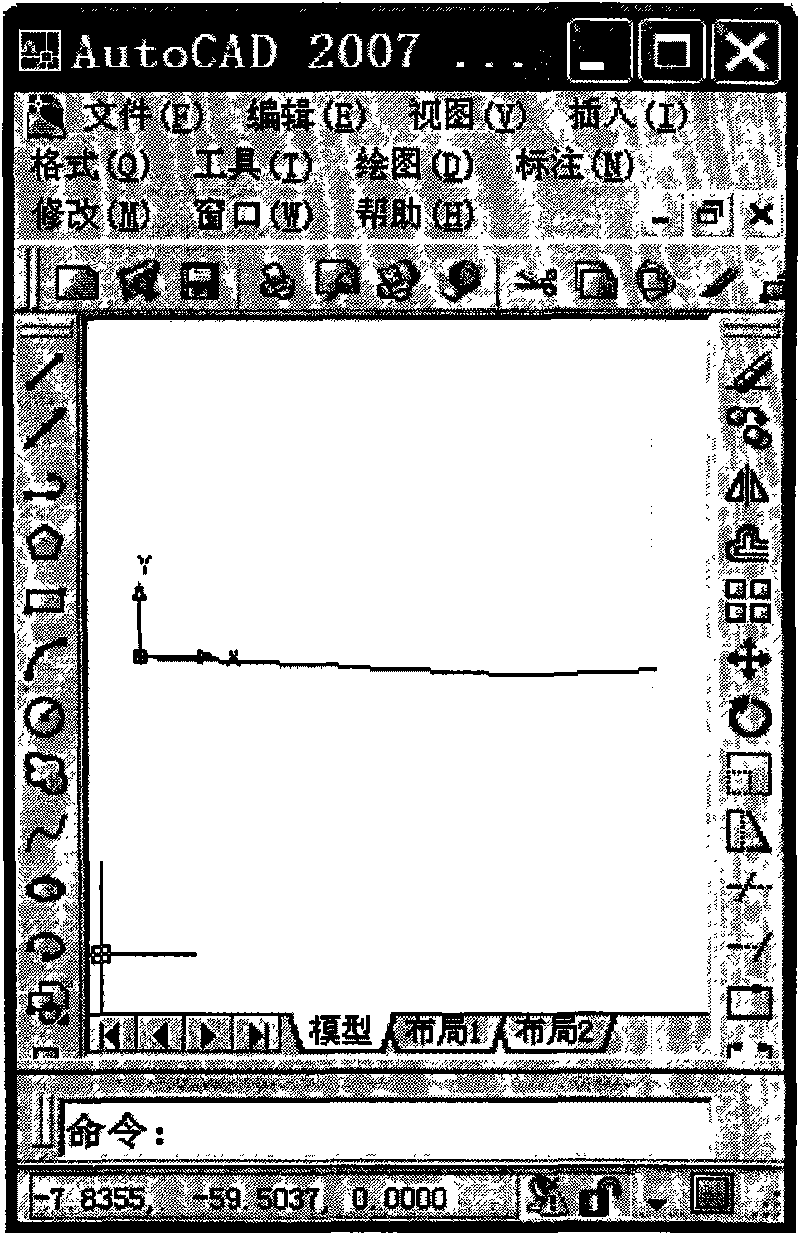

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the drawings and specific embodiments.

[0019] The present invention is realized through the following steps:

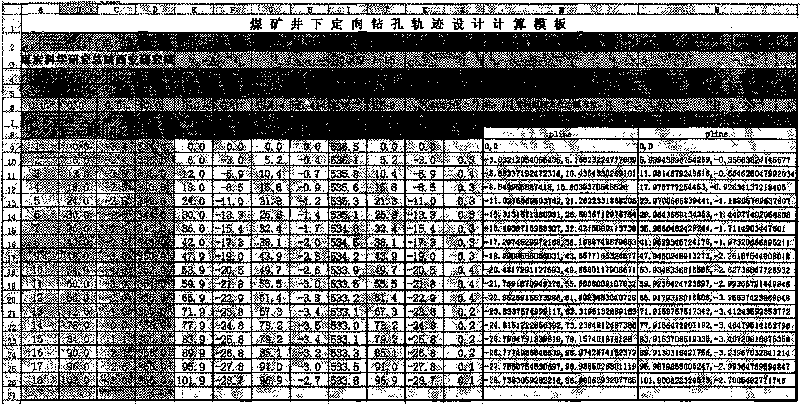

[0020] (1) Establish an Excel spreadsheet, the area is set with data input area, trajectory parameter calculation area, AutoCAD command code area, and drawing data area;

[0021] See figure 1 , Cells A3:N3, A6:N6, and A9:26 are the data input area, cells E9:L26 are the track parameter calculation area, cells M8:N8 are the AutoCAD drawing command code area, and cells M9:N27 are the drawing data Area.

[0022] Enter basic data in cells A3:N3, A6:N6, and A9:26, including design unit, drill site number, drill hole number, design orifice coordinates, coordinate longitudinal line position, local magnetic declination, orifice elevation, AutoCAD drawing scale, etc.; input AutoCAD drawing command code in the AutoCAD drawing command code area, which can be line drawing commands such as line, pline, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com