Lateral DMOS transistor and method of fabricating thereof

A technology of transistors and body regions, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems such as the limitation of drain-source impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Reference will now be made in detail to specific embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

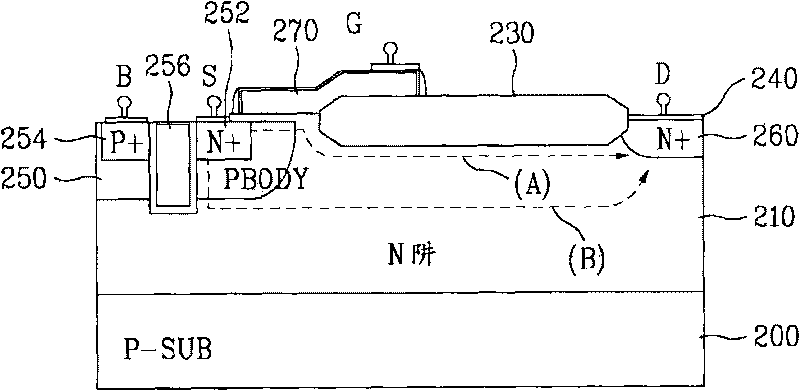

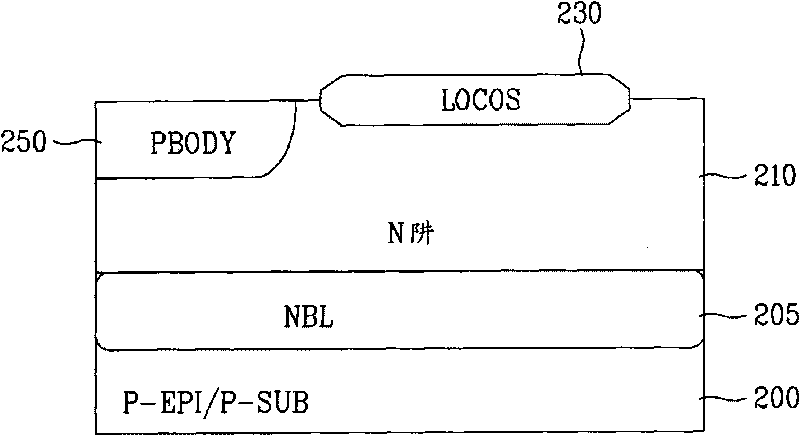

[0022] figure 2 A cross-sectional view showing an LDMOS transistor according to a preferred embodiment of the present invention is shown. refer to figure 2 , the LDMOS transistor includes: N well 210, formed on the P-type semiconductor substrate 200; LOCOS 230, formed on the surface of the N well 210; drain region 260, formed in the N well 210, on one side of the LOCOS 230; and doped N + Type impurity source region 252, doped with P + Type impurity source contact region 254; and a second gate electrode 256 having a trench shape, formed in the P-type body region 250, which is separated from the drain region 260 by a certain distance, in the LOCOS 230 on the other side of the .

[0023] Source region 252 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap