Pipeline connector

A technology for pipe connectors and pipes, which is applied in the direction of pipe connection arrangement, pipe/pipe joint/fitting, sealing surface connection, etc., can solve the problems of increased drawing force, easy leakage, insufficient drawing force, etc., to achieve increased Large pulling force, avoid leakage, and reduce the effect of pipeline flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings.

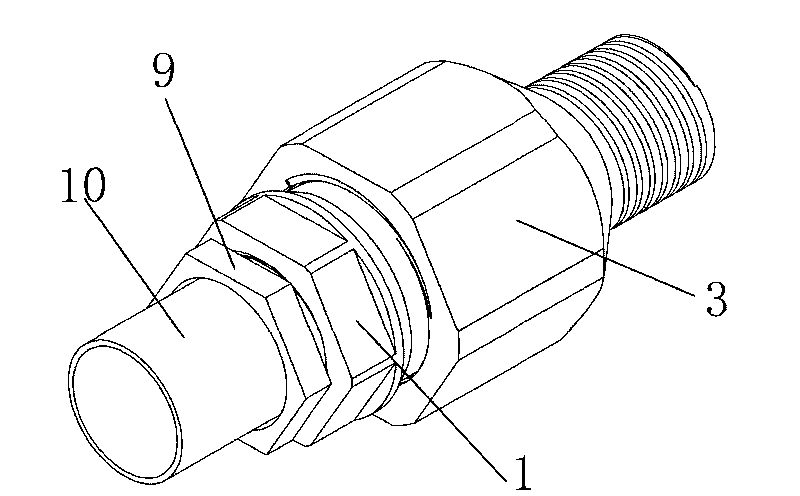

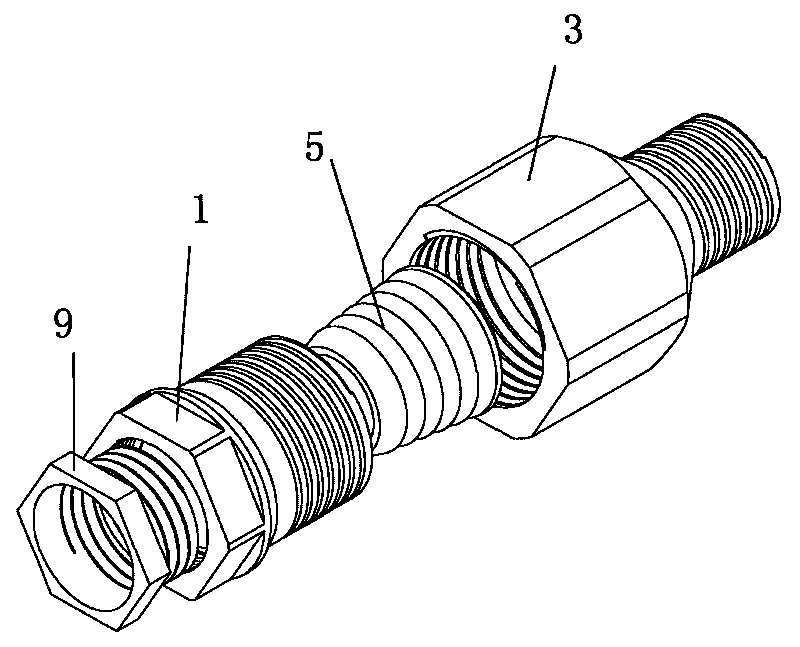

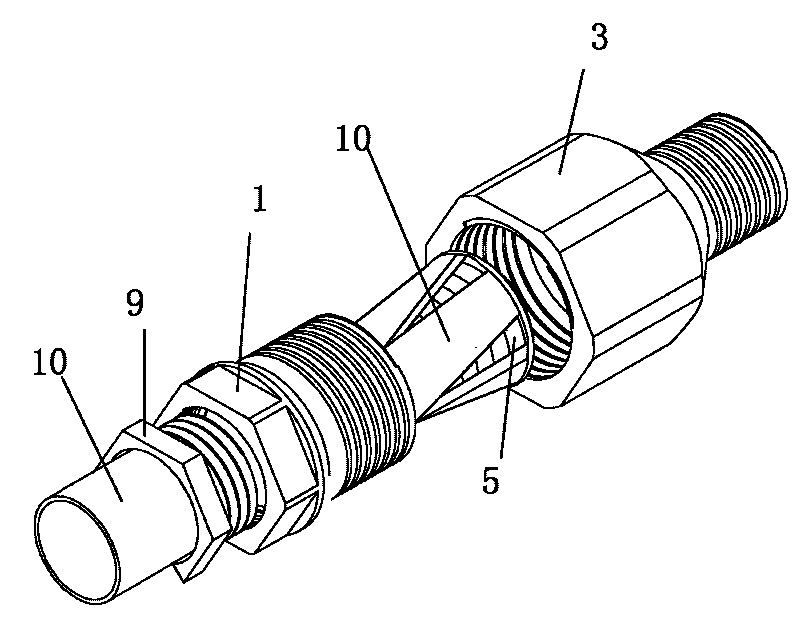

[0065] refer to Figure 1 to Figure 9 , a pipe connector, including a compression nut 1, the inner cavity of the compression nut 1 is an installation channel 2 for the pipeline 10 to pass through, and the inner side of the compression nut 1 is provided with a connecting section, and the connecting section and the pipe fitting The main body 3 is sealed and connected. The outside of the installation channel 2 is cylindrical to match the pipe. The inside of the installation channel 2 is provided with a tapered section 4. The diameter of the tapered section 4 changes from large to small from the inside to the outside. The pipe connector also includes an inner cone 5 for extending into the expanded pipe end, the inner cavity of the inner cone 5 is a water flow channel, and the outer diameter of the inner cone 5 is from the inside to the outside From large to small, the inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com