Method and device for measuring errors of face gear by scanning single-face meshed rolling points

A technology of single-face meshing and measuring devices, which is applied in the direction of measuring devices, machine gear/transmission mechanism testing, optical devices, etc., can solve difficult gear processing system diagnosis and analysis, difficult full-scan measurement, and obtain comprehensive transmission of face gears Accuracy and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

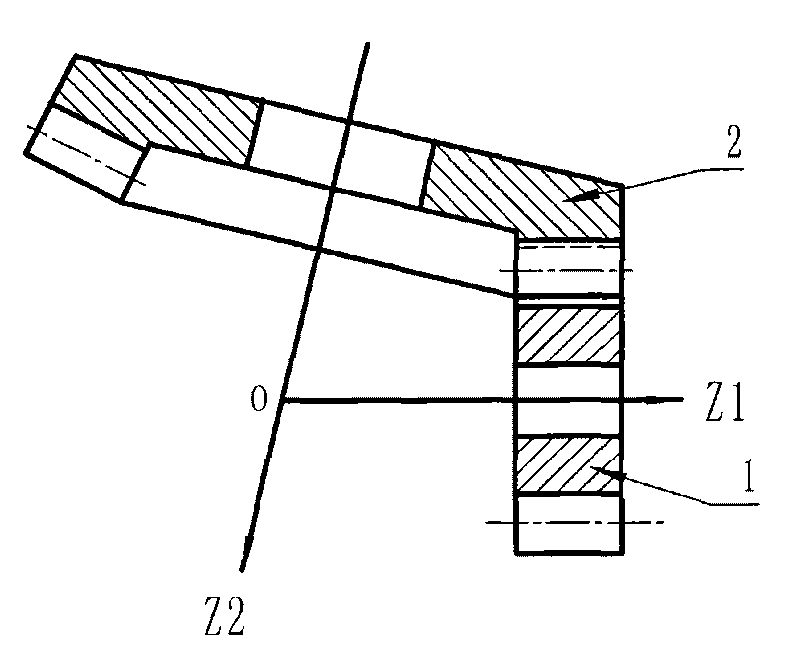

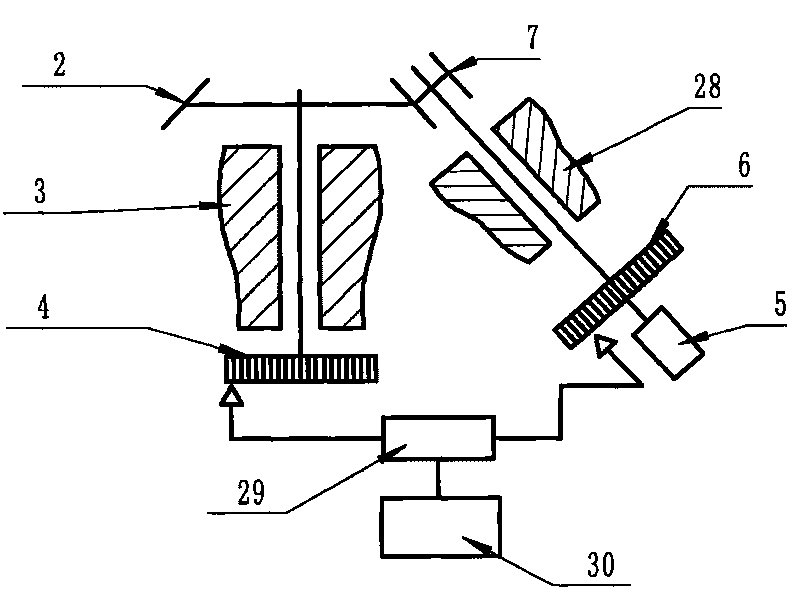

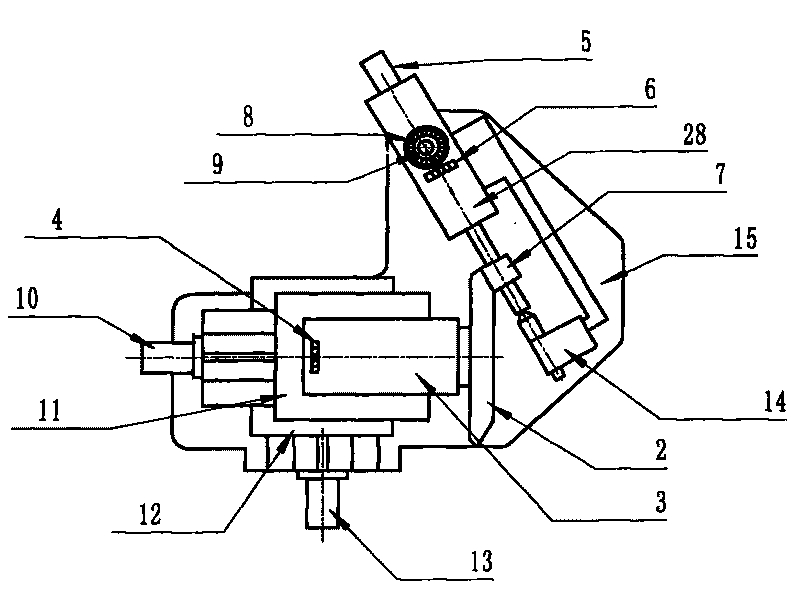

[0047] Embodiment 1 adopts such as image 3 In the horizontal structure shown, the measuring element mounting shaft system 28 and the face gear mounting shaft system 3 are installed horizontally. The measured surface gear 2 is accurately installed on the measured gear precision shaft system 3, and a high-precision circular grating 4 is coaxially installed on the shaft. Measuring element 7 (with tooth profile / or tooth direction measuring ridge) is accurately installed on measuring element rotating main shaft system 28 and supported by support tailstock 14, and high-precision circular grating 6 is coaxially installed on shafting system 28 . The position adjustment of the measured surface gear 2 and the measuring element 7: the measured surface gear shaft system component 3 is installed on the axial carriage 11 with a high-precision long grating, and the carriage is driven by a motor 10 . The axial carriage is fixed on the radial adjustment carriage 12 at the same time, and the ...

Embodiment 2

[0049] Embodiment 2 adopts such as Figure 4 In the vertical structure shown, the face gear installation shaft system 3 is installed in the vertical direction, and the measuring element installation shaft 28 is installed obliquely. Similarly, the face gear 2 and the measuring element 7 are installed on the precision shaft system 3, and circular gratings are coaxially installed on each shaft system. The position adjustment of the measured surface gear 2 and the measuring element 7: the measured surface gear shaft system component 3 is installed on the radial adjustment carriage 12 with a high-precision long grating, and the carriage moves in the radial direction through the rotation handle 19 , the position of the carriage is determined according to the theoretical position of the face gear transmission; in addition, the relative height of the measuring element 7 and the face gear 2 can be adjusted through the height adjustment handle 16, the height adjustment carriage 17 also ...

Embodiment 3

[0051] Embodiment 3 adopts such as Figure 5 In the variant vertical structure shown, the face gear installation shaft system 3 is installed obliquely in the vertical plane, and the measuring element installation shaft system 28 is installed horizontally. The difference between it and the vertical mechanism is that the gear shaft system part 3 of the measured surface can swing in the vertical plane, and the angle adjustment between the measured surface gear 2 and the measuring element 7 is adjusted by the angle adjustment mechanism 21 . The acquisition and processing of the signal are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com