Material discharging device with air distribution function

A technology of unloading device and gas function, applied to the unloading device on the moving bed reactor, in the field of unloading device, it can solve the problems of no gas distribution function, blockage of the moving bed reactor, etc., to ensure fluency and avoid dead ends area, the effect of prolonging the gas-solid contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

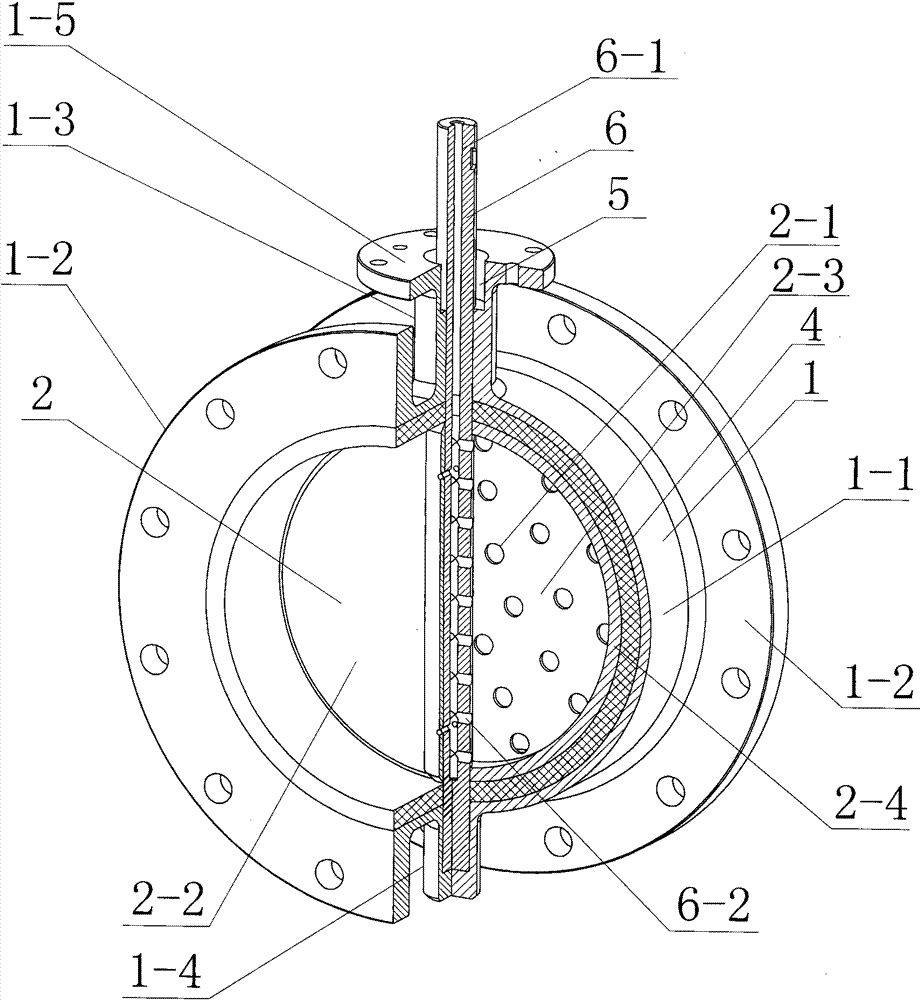

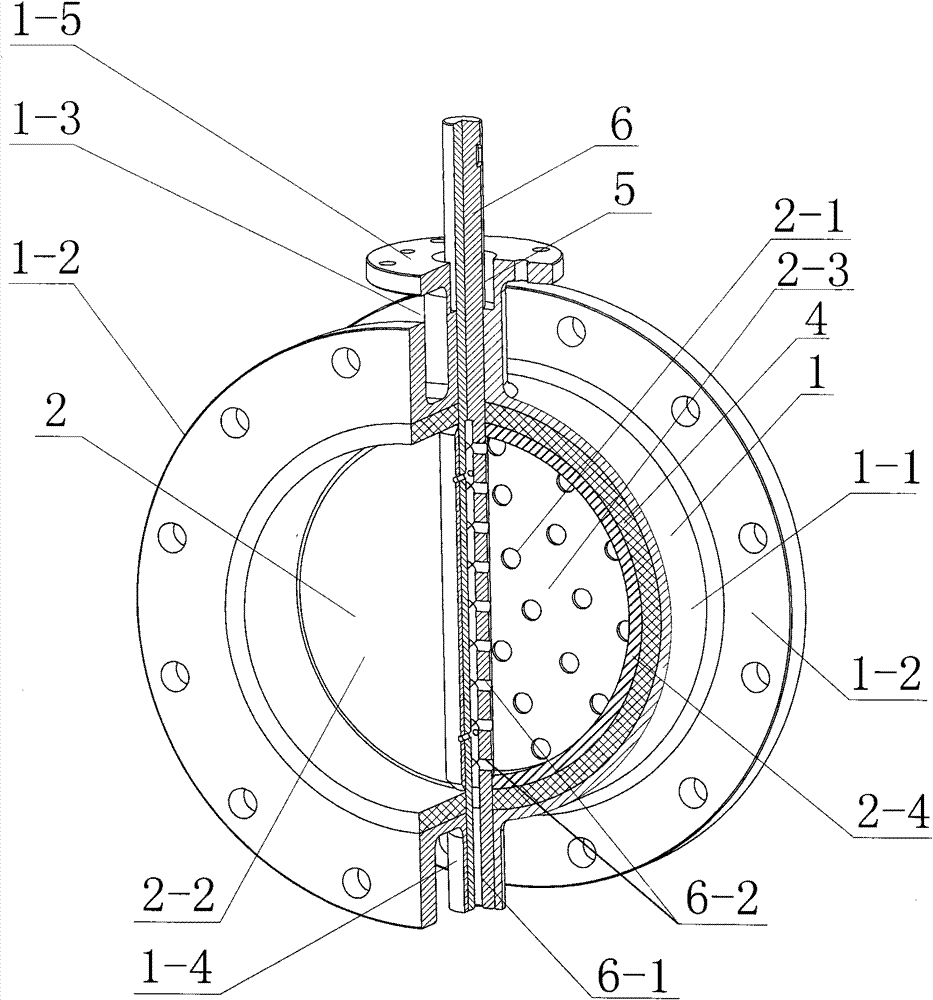

[0007] Specific implementation mode one: as Figure 1~6 As shown, the unloading device with air distribution function in this embodiment includes a device housing 1, a rotating shaft 6 and a plurality of hoods 14, and the device housing 1 consists of a cylinder 1-1, two large flanges 1-2, The first shaft sleeve 1-3, the second shaft sleeve 1-4 and the small flange 1-5 are composed, the cross section of the cylinder 1-1 is a ring, and the two large flanges 1-2 are parallel Fixed on both ends of the cylinder 1-1, the first sleeve 1-3 and the second sleeve 1-4 are arranged on the opposite side wall of the cylinder 1-1 in the radial direction, and the first sleeve 1 -3 and the second shaft sleeve 1-4 communicate with the inner cavity of the cylinder 1-1, the small flange 1-5 is fixed on the first shaft sleeve 1-3, and the discharge device also includes The air distribution cavity 2, the shape of the air distribution cavity 2 is in the shape of a round cake, and a plurality of fir...

specific Embodiment approach 2

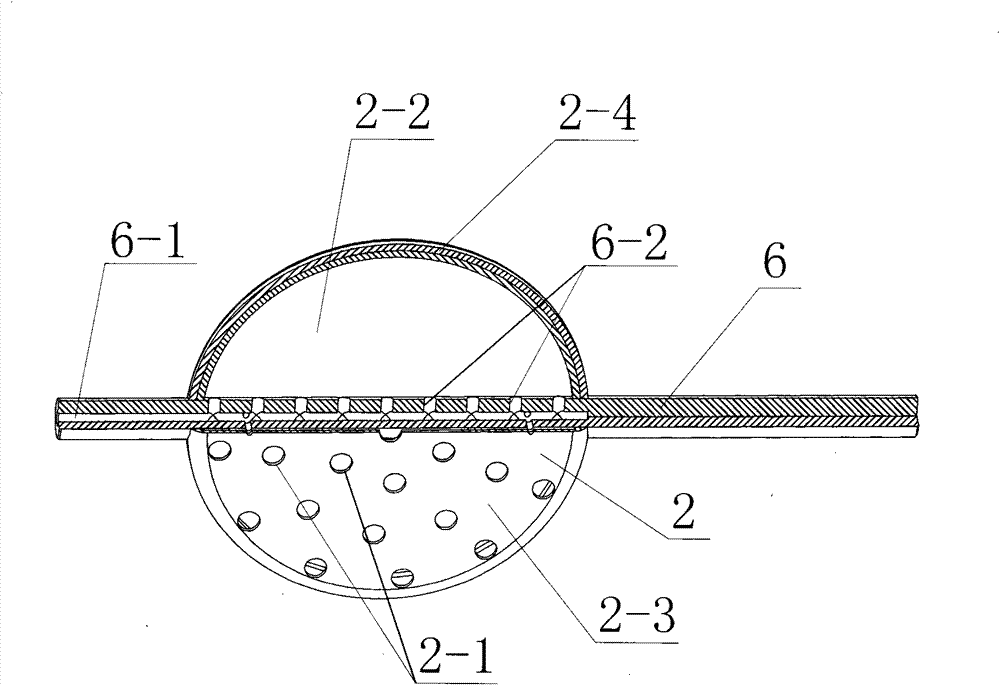

[0008] Specific implementation mode two: as Figure 1~3 As shown, the air distribution cavity 2 in this embodiment is composed of a valve plate 2-2, an air distribution plate 2-3 and a ring body 2-4, and the valve plate 2-2 is parallel to the air distribution plate 2-3 Setting, the valve plate 2-2 and the air distribution plate 2-3 are fixed together through the ring body 2-4 to form the air distribution cavity 2, and the air distribution plate 2-2 is provided with several evenly distributed The first through hole 2-1. With such a design, the valve plate 2-2 and the air distribution plate 2-3 are combined into one body, which has the function of unloading and air distribution. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: as Figure 4 As shown, the hood 14 in this embodiment is composed of a hood head 14-1 and a connecting end 14-2, the cross sections of the hood head 14-1 and the connecting end 14-2 are circular, and the hood head 14-1 communicates with the connection end 14-2, and a plurality of third through holes 14-3 are opened on the side wall of the hood head 14-1 along the circumferential direction. Such a design can change the direction of air outlet from the plurality of first through holes 2 - 1 on the air distribution cavity 2 , and can prevent solid-phase reactants from entering the air distribution cavity 2 . Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com