Excess material cutting mechanism for curtain piece knitting machine

A cutting mechanism and weaving machine technology, applied in mechanical equipment, sugarcane machining and other directions, can solve the problems of high mechanism cost, complicated cutting mechanism for residual material, etc., and achieve the effect of smooth cutting motion and simple cutting mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

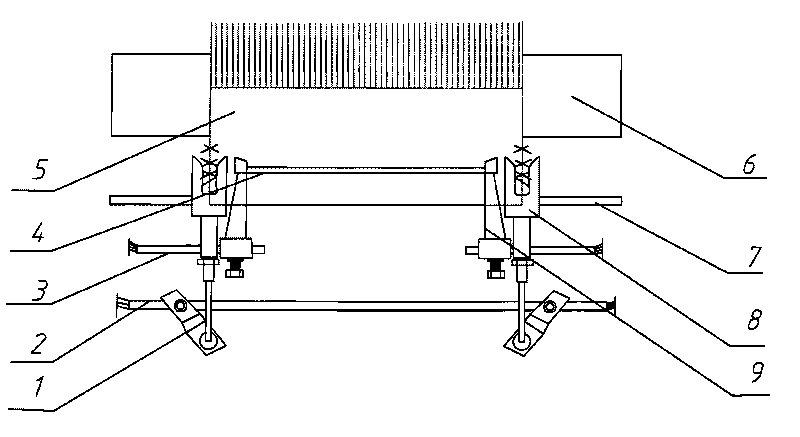

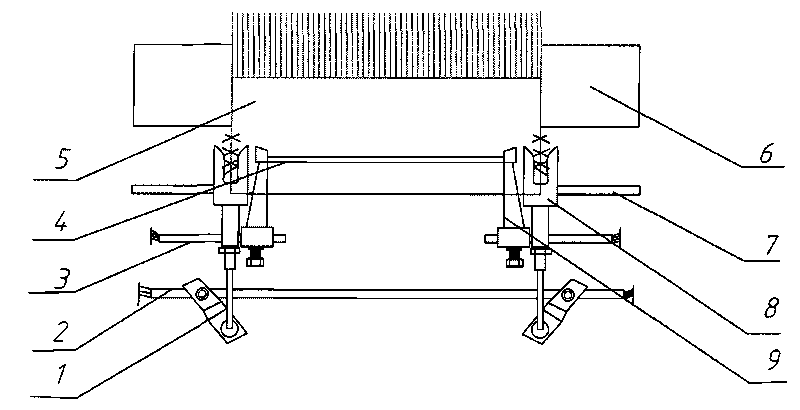

[0012] See attached figure 1 , a transmission mechanism of a curtain weaving machine, comprising a cutter support 1, a bracket connecting rod 2, a support rod 3, a drum 4, a straw mat 5, a fixed support plate 6, a straw mat steering rod 7, a cutter 8, a bracket 9.

[0013] The fixed support rod 3 is connected with the support 9 of the drum 4, and the drum 4 can roll when the straw mat 5 moves downward.

[0014] Described cutting knife 8 is stationary on support 9, and the rear surface of cutting knife 8 is against the edge surface that straw mat 5 has redundant forage.

[0015] The bracket 9 is connected to the support rod 3, symmetrically arranged left and right, and supports the drum 4, and the straw mat 5 is also attached to the fixed support plate 6 at the back, and the straw mat 5 is interposed between the drum 4 and the fixed support plate 6 between.

[0016] Described straw mat 5 rear bottoms are fixed with straw mat turning bar 7, can remove the straw mat 5 that exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com