High capacity tire

A tire and tread technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems that the rubber composition of the sidewall cannot be shared, the side mold cannot be used universally, and the production efficiency is low. Achieve the effects of suppressing cracks, suppressing shoulder shedding and wear, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

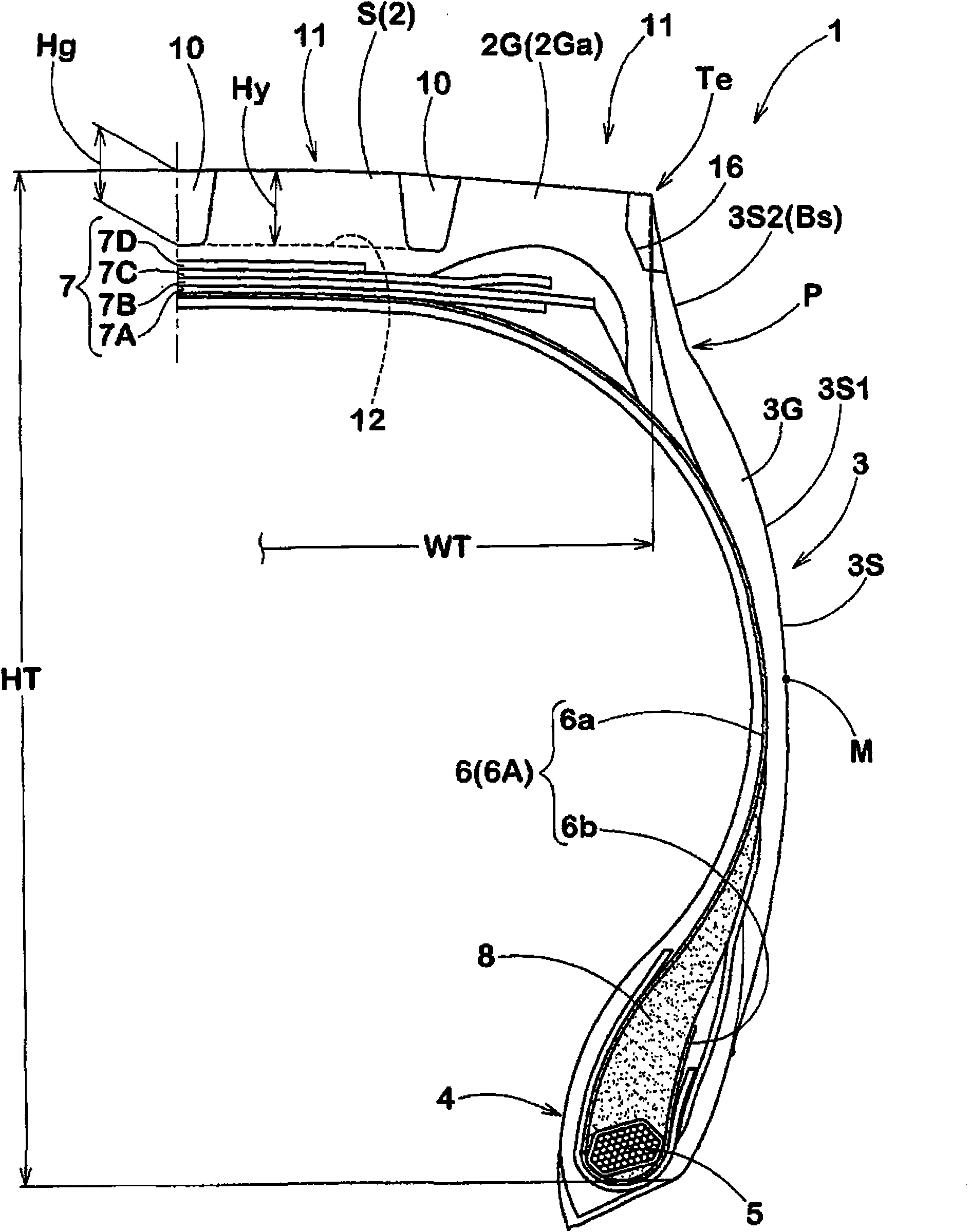

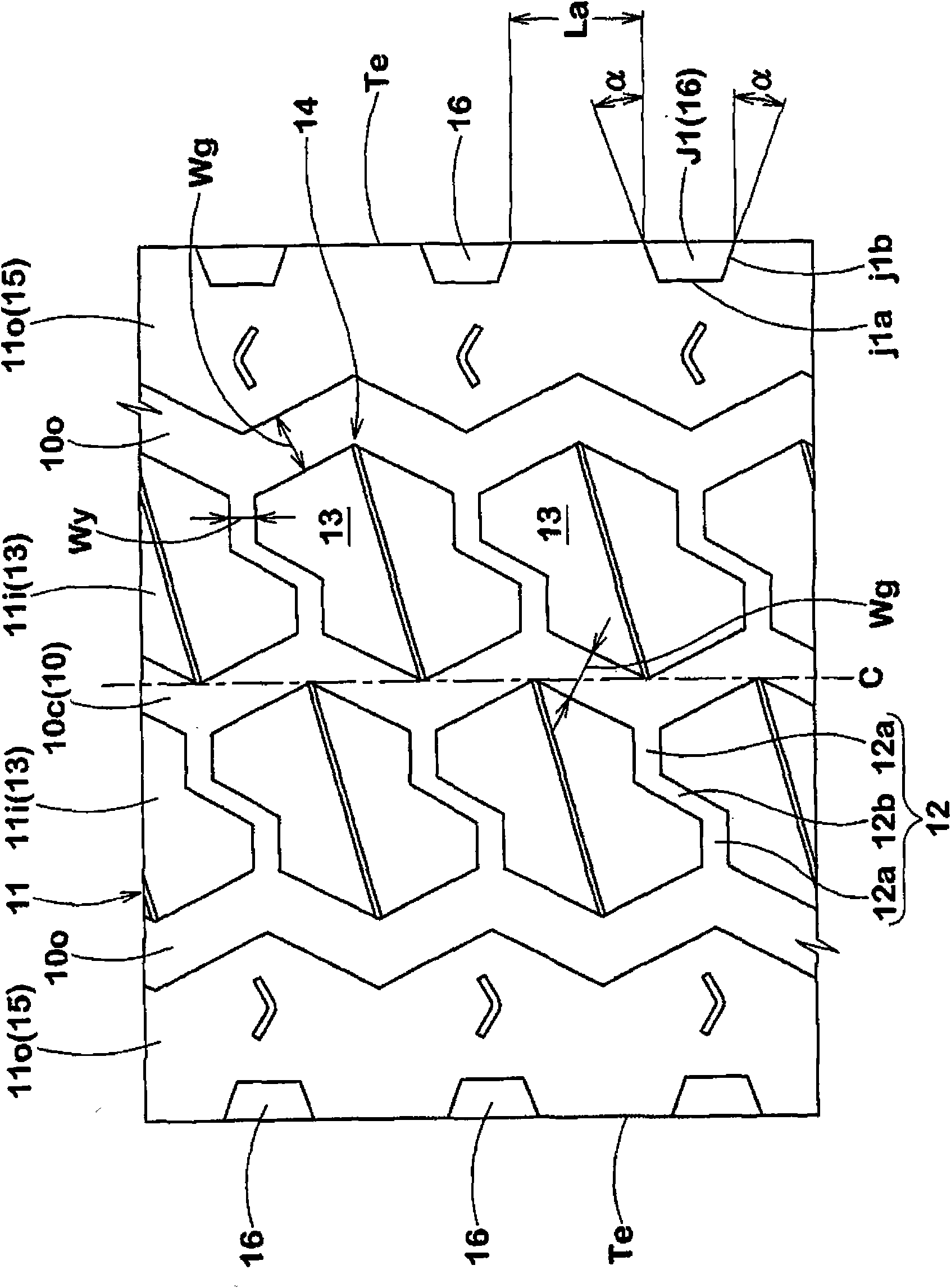

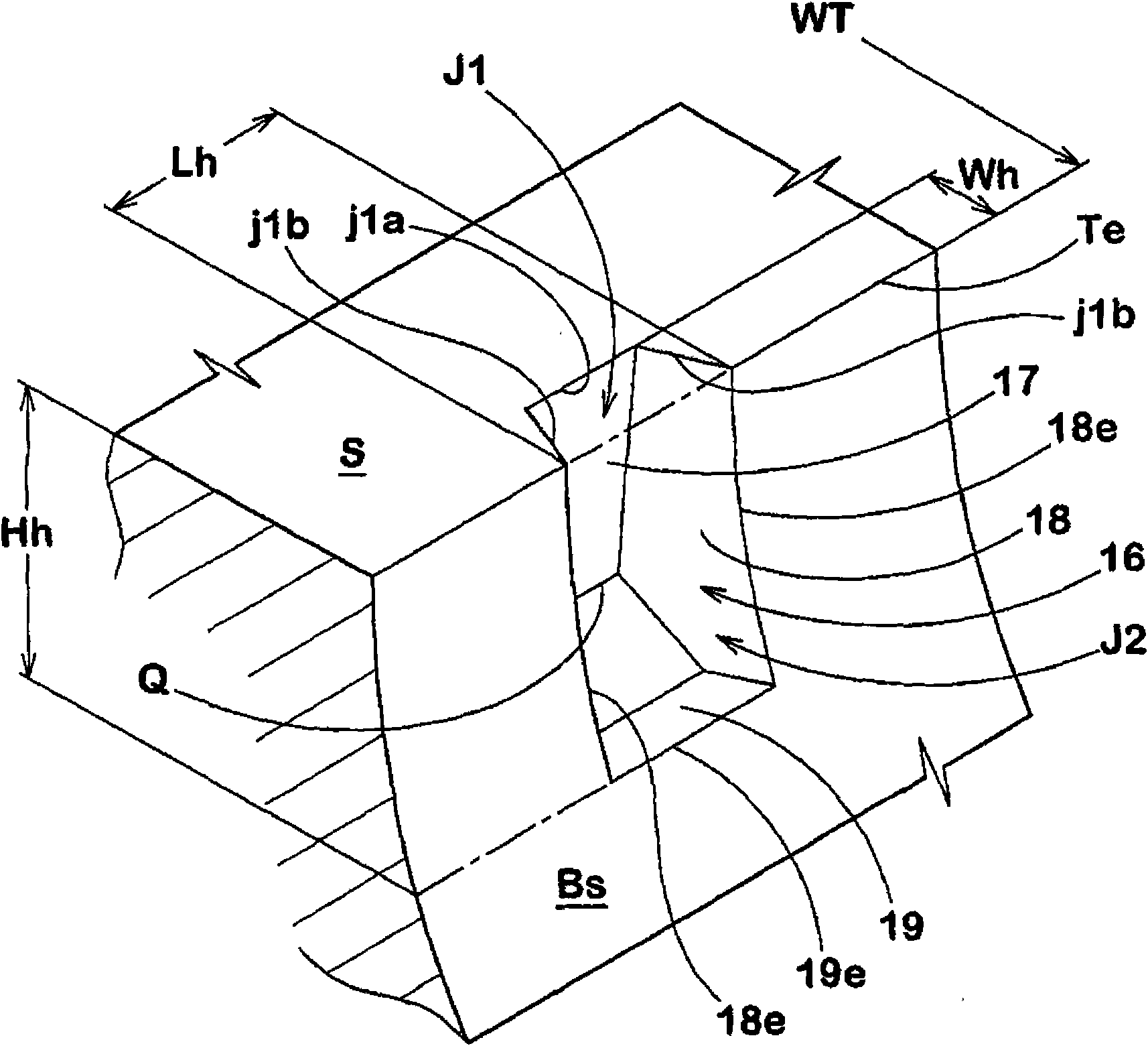

[0059] by figure 2 The tread pattern shown is a basic pattern, and a truck tire (TL295 / 75R22.5) in which grooves 16 were formed on the tread edge Te was trial-produced using the specifications shown in Table 1. Then each test tire was tested for crack resistance and partial wear resistance, and the results were compared. For each tire, the opening shape J1 of the groove 16 on the tread surface S and the cross-sectional shape parallel to the tread surface S are both trapezoidal, and the angle α of the side j1b (or side portion 18) relative to the tire axial direction Both are 50°. And each surface part 17-19 intersects by the arc part of curvature radius 4mm. In addition, the symbol LT in the table indicates the tire outer peripheral length (3235mm) on the tread contact point Te, the symbol WT indicates the tread contact width (212mm), and the symbol HT indicates the tire section height (229mm). Each tire is fixed.

[0060] (1) Crack resistance:

[0061] Install the test t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com