Automatic collision avoidance system and method of port cargo ship unloader

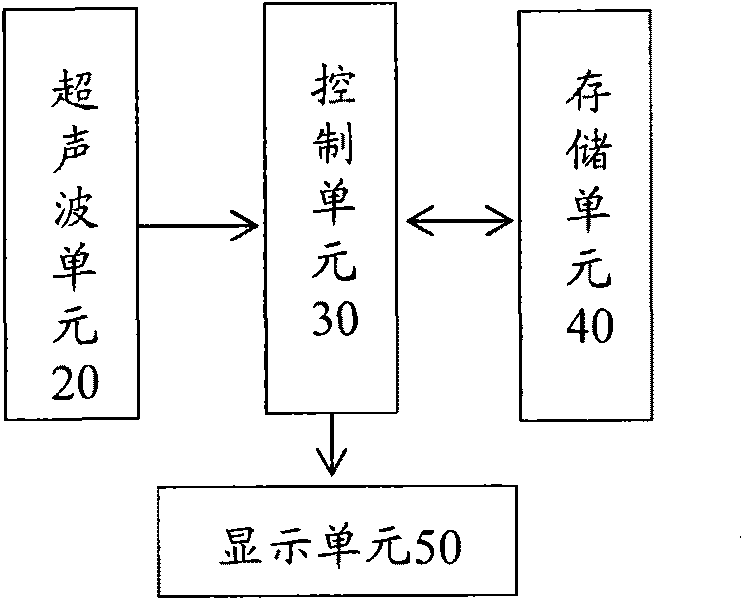

A technology of anti-collision system and ship unloader, which is applied in the direction of radio wave measurement system, loading/unloading, instruments, etc. It can solve the problems of not being able to judge whether there is a cleaning machine in the cabin, limited time, invalid alarm signal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

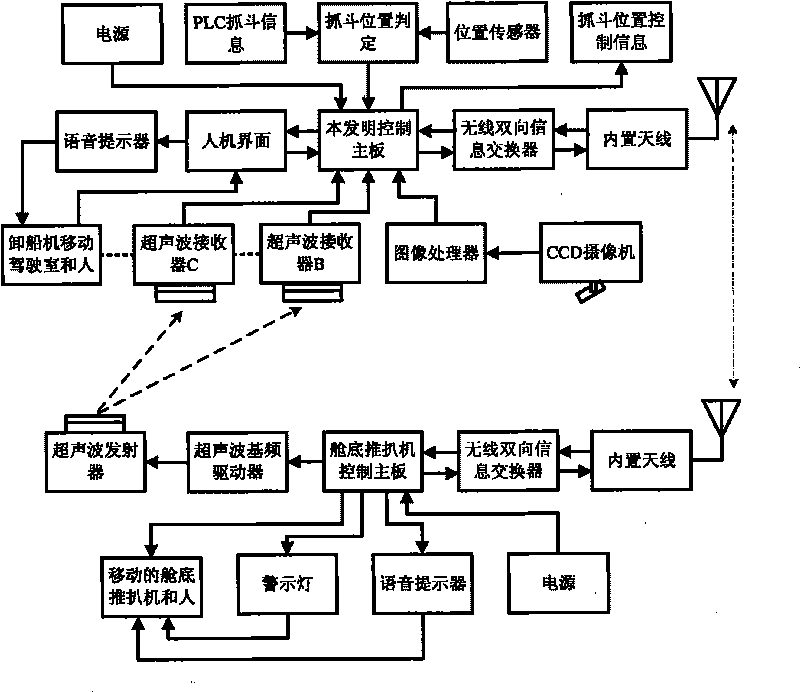

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

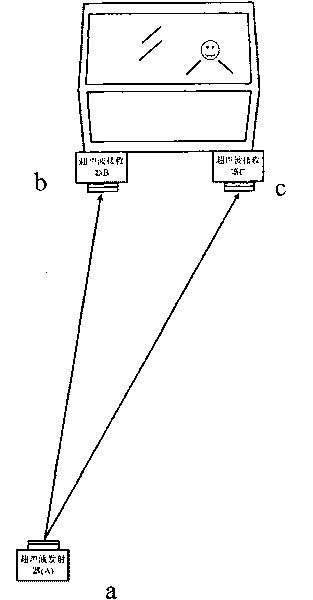

[0044] Here we first introduce the division of operation areas during unloading operations, see Image 6 and Figure 9 , the unloading operation is that when the cargo ship is at the port, the grab 03 of the ship unloader at the wharf grabs the material 13 in the cargo ship cabin 12 from a high place, and in order to cooperate with the grab 03 of the ship unloader, the cabin is often cleared The machine 04 is put into the bottom of the cargo ship cabin 12 to push the material 13. In order to prevent the collision between the cleaning machine 04 and the grab bucket 03, the entire operation area is divided into the safe operation area of the cleaning machine and the grab operation area (also called the grab operation area). One of the important purposes of the present invention is exactly when the cabin cleaning machine 04 en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com