Shedding mechanism for air jet loom

A technology of opening mechanism and air-jet loom, which is applied in other opening mechanisms, looms, textiles, etc., can solve problems such as large vibration of rods and breakage of warp yarns, and achieve the effect of low vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

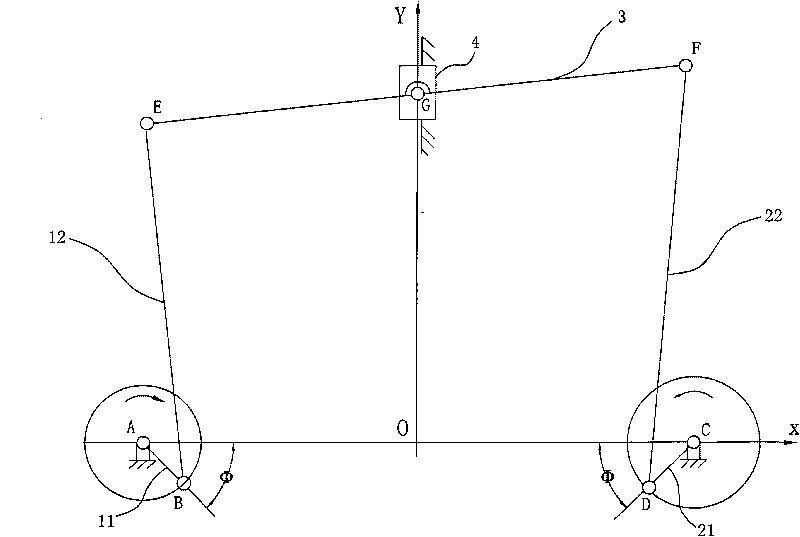

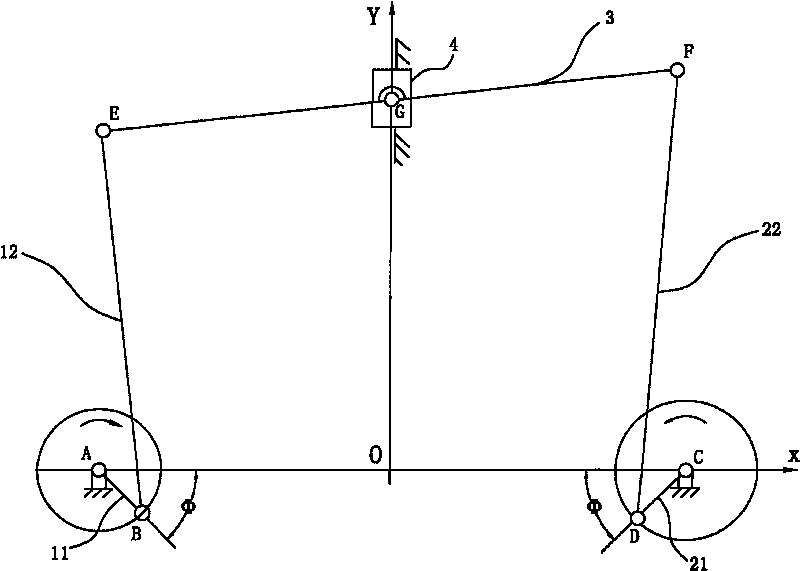

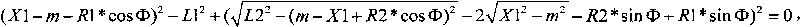

[0016] On the air-jet loom, the shedding mechanism is used to perform the shedding movement of the warp yarns. The present invention starts from the technical requirements of lifting the warp yarns, uses as few rods as possible to realize the shedding action, and at the same time strives not to generate extra force and pressure on the rods as much as possible. The torque is mainly considered on the geometric dimensions of each moving rod, and a plane opening mechanism that meets the actual situation of the current high-speed air-jet loom is provided. The content of the present invention will be explained in detail below in conjunction with specific embodiments.

[0017] see figure 1 The plane opening mechanism shown is mainly composed of a left crank 11, a right crank 21, a left connecting rod 12, a right connecting rod 22, a pendulum 3 and a slider 4, and the A end of the left crank 11 is hinged to the frame , the B end is hinged to the left link 12, the C end of the right c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com