Method and system for checking device

A technology of equipment calibration and parameters, which is applied in the field of equipment calibration, can solve the problems of long query time, loss of test reports, and inability to reflect the test status in real time, and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

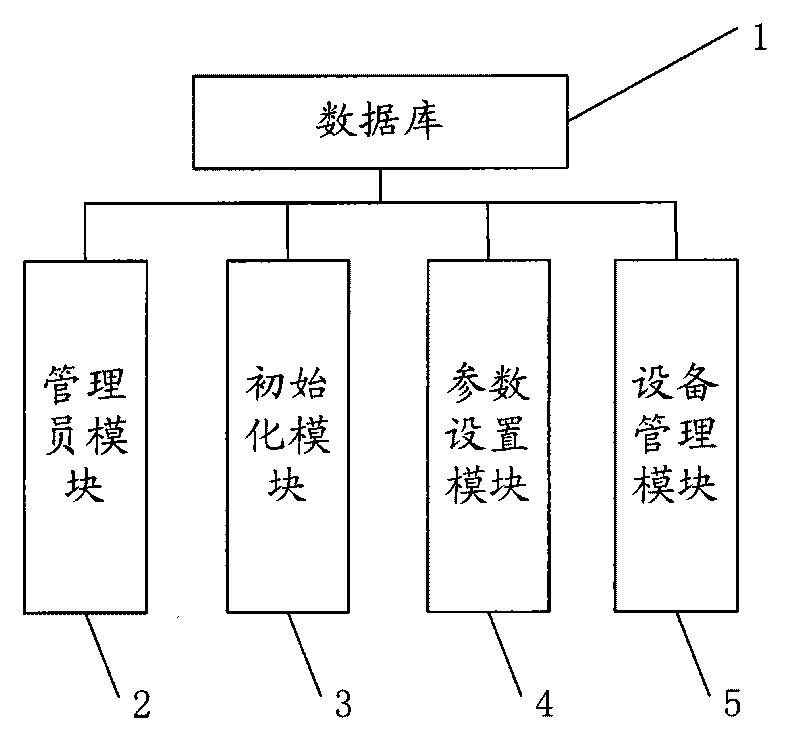

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] One of the equipment verification method of the present invention is used to verify the safety equipment, and some parameters of the safety equipment are all stored in a database, which includes the following steps:

[0021] Set the administrator step, enter or modify the administrator's name, password, and set the administrator's level or authority;

[0022] The initialization step initializes all data parameters in the database;

[0023] In the step of setting parameters, several parameters of safety appliances are respectively set and stored in the database. The parameters of the safety appliances set include equipment classification, unit, department, tool category, team and group, and substation;

[0024] In the step of managing devices, perform management operations on the security appliances that need to be managed, including adding device information, queryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com