Flotation machine driving device

A driving device and flotation machine technology, applied in flotation, solid separation, etc., can solve the problem of increased stall torque at startup, and achieve the effects of large stall torque, convenient belt tensioning, and self-heavy motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

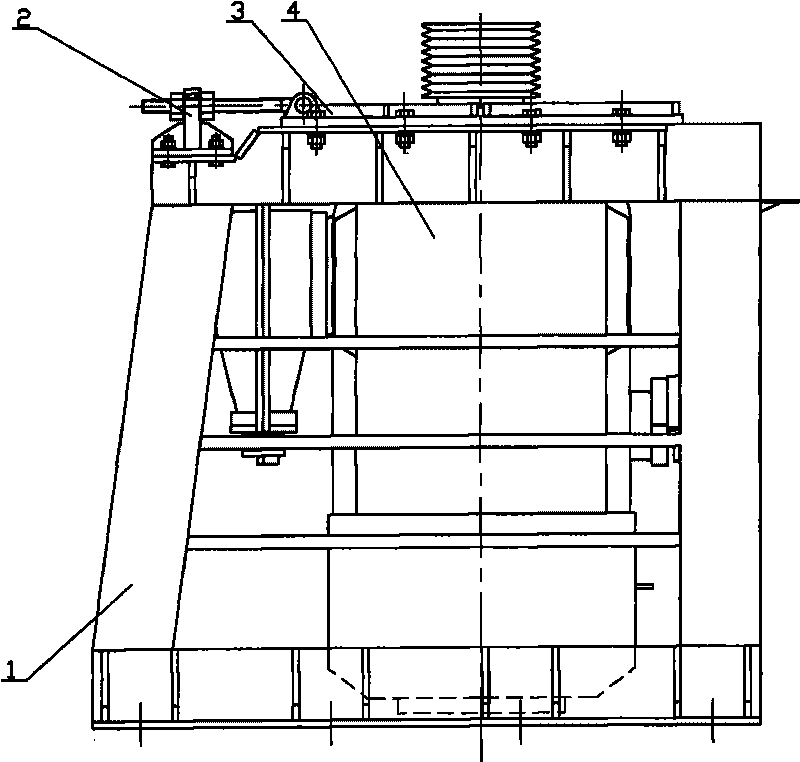

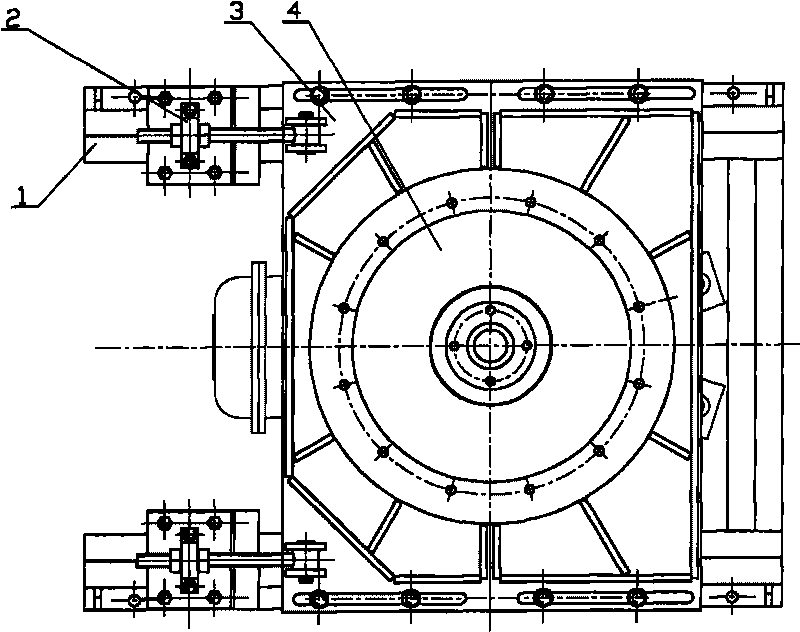

[0021] Such as figure 1 , figure 2 As shown, the driving device of the flotation machine in this embodiment includes a base 1 , an adjusting device 2 , a motor bracket 3 and a motor 4 . The motor 4 is set on the motor support 3 , and the adjusting device 2 and the electrode support 3 are set on the base 1 .

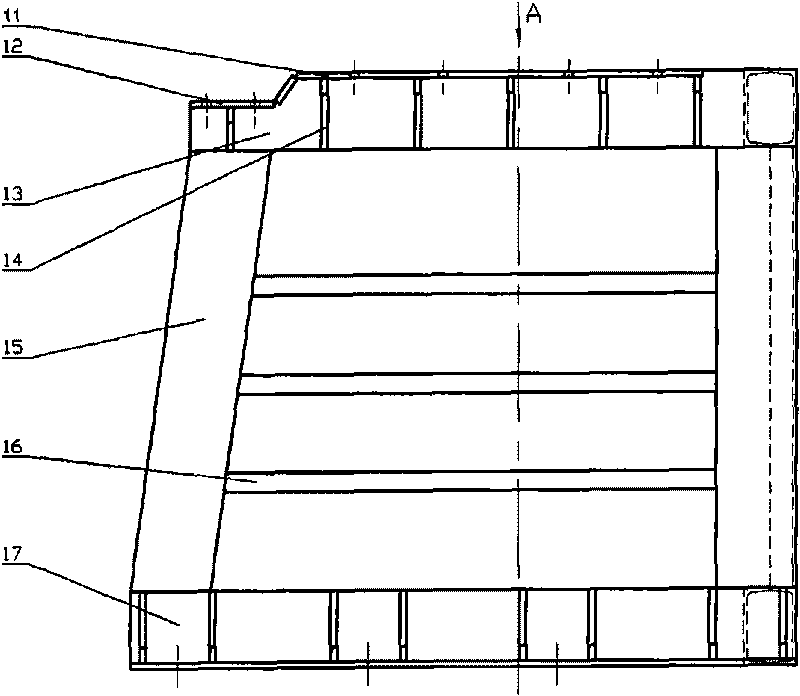

[0022] Such as image 3 , Figure 4 As shown, the base 1 of the present embodiment is welded by channel steel, steel plates and reinforcement plates, and is a cubic frame structure as a whole, mainly including an upper beam 13, an upper beam steel plate 11 above the upper beam 13, a column, a lower Crossbeam 17 and the lower crossbeam steel plate 18 that is located at the lower crossbeam 17 below. Wherein, the upper beam steel plate 11 is a rectangular steel plate with several bolt holes arranged in a line, which is welded o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com