Method for straightening steel plate

A steel plate and straightening technology, which is applied in the field of improving the quality of steel plates, can solve problems such as poor straightening effect, crushed steel plates, and high waste rate, and achieve the effect of improving the pass rate and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Straightening method of lateral ladle curvature:

[0020] Use jack pressure as the pressure source to squeeze and straighten the steel plate. The specific steps of the method are:

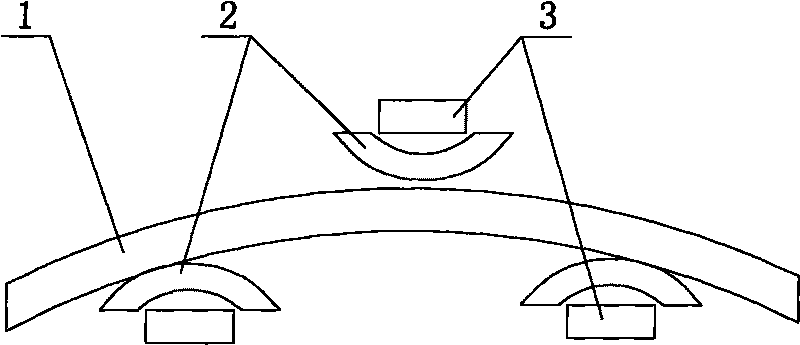

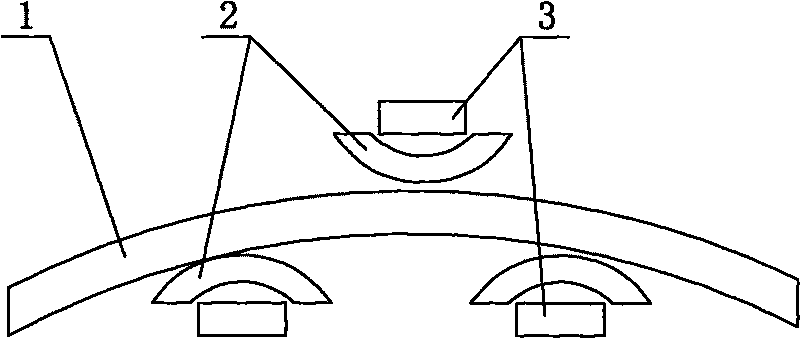

[0021] ① Before straightening, according to the deformation state and degree of deformation of the steel plate, place two pad irons 3 and arc spacers 2 at appropriate positions on the straightening platform, and place the steel plate on the straightening platform through the roller table;

[0022] ② According to the actual deformation of the steel plate, select the position where the steel plate is first compressed, place an arc-shaped gasket at this position on the upper surface of the steel plate, and place a pad iron in the depression at the upper end of the arc-shaped gasket;

[0023] ③Start the jack pressure leveler, press the pressure head down to squeeze the pad iron, and the pressure is transmitted to the arc-shaped gasket to squeeze the deformed part of the steel plate;

[0024] ④C...

Embodiment 2

[0031] Straightening method for ladle curvature in the length direction:

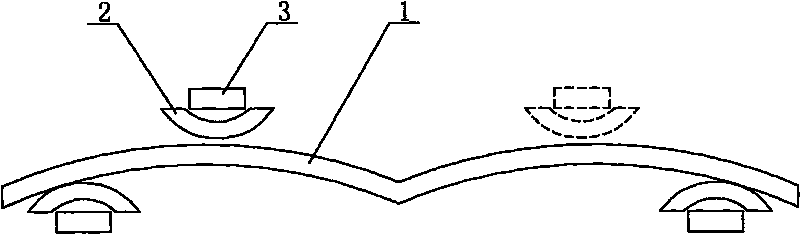

[0032] Such as Figure 5 As shown, place a parallel iron 3 and an arc-shaped gasket 2 on the head of the steel plate 1 in the longitudinal direction, and move another parallel iron 3 and an arc-shaped gasket 2 along the length direction for a certain distance, and the pressure head squeezes the steel plate 1 on both sides. At the highest point between the arc-shaped spacers 2, gradually move the pad iron 3 and the arc-shaped spacer 2 under the steel plate 1 along the length direction of the steel plate 1. After each movement, use the pressure head to pass through the spacer 3 and the arc-shaped spacer 2 Squeeze the highest point of the steel plate 1 until the straightening is complete.

[0033] The thickness of the lower gasket is 10mm, and the location of the gasket is shown in the parameter table (straightening from east to west)

[0034] Steel plate thickness

[0035] Steel plate...

Embodiment 3

[0037] Straightening method of bridge steel plate:

[0038] 1. If Figure 6 As shown, a flat steel plate 1 is first placed on the 1,000-ton pressure straightening roller table, and then the head of the bridge-shaped steel plate 1 is placed on the tail of the flat steel plate 1 meter away, and the flat steel plate moves forward on the roller table, so that the bridge-shaped steel plate 1 Bring in the straightening platform.

[0039] 2. Use the pressure head to squeeze the highest point of the steel plate 1 entering the straightening platform, and then use this as the starting point to straighten every 200mm towards the head of the steel plate until the head of the steel plate, and then start from the starting point and move toward the steel plate Straighten every 200mm in the direction of the tail until the tail of the board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com