Elevating gasket base

A pad seat and lifting technology, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of high friction, low lifting accuracy and sensitivity, and inflexible pad seat lifting, etc. problems, to achieve the effect of flexible and accurate movement, small friction resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

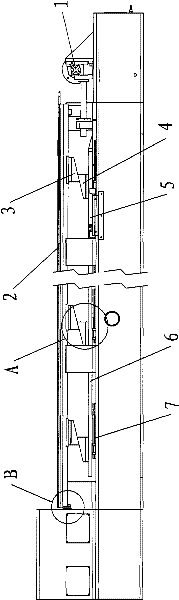

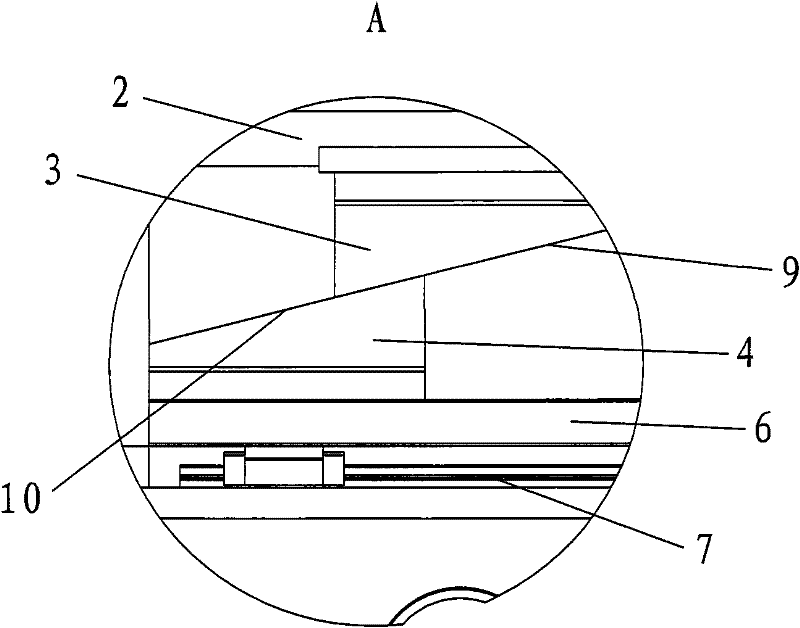

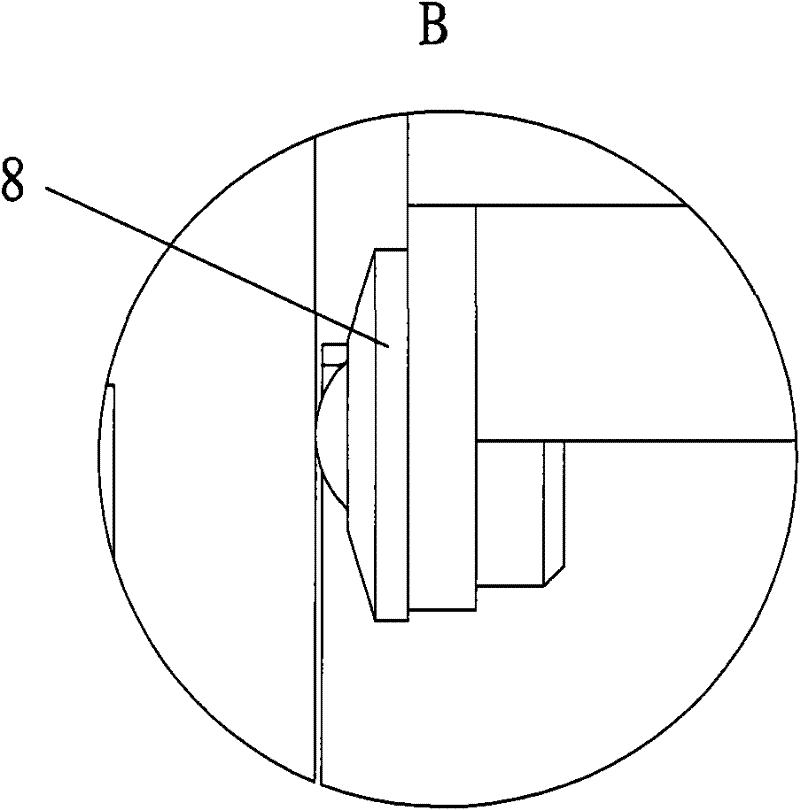

[0012] The present invention will be further described below by means of embodiments in conjunction with the accompanying drawings.

[0013] As shown in the accompanying drawings, a lifting cushion seat includes a driving device 1, a cushion seat 2, an upper wedge 3 fixed on the lower surface of the cushion seat 2, and a The lower movable seat 6 which is under the cushion seat 2 and can move back and forth, the lower inclined wedge 4 fixed on the lower movable seat 6 and corresponding to the upper inclined wedge 3; the cushion seat 2 The left and right and front and rear degrees of freedom are limited and can only move up and down. The left and right and up and down degrees of freedom of the lower moving seat 6 are limited and can only move forward and backward; the drive device 1 includes a motor, a reducer, a transmission screw and Nuts etc., wherein the nut is fixedly connected with the lower moving seat 6, and the driving device 1 drives the lower moving seat to move forwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com