Hand-held electric buffing attachment

A polishing device and a hand-held technology, which is applied in the field of hand-held electric polishing devices, can solve the problems of unevenness, low work efficiency, easy to dirty hands, etc., and achieve the effect of good uniformity and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

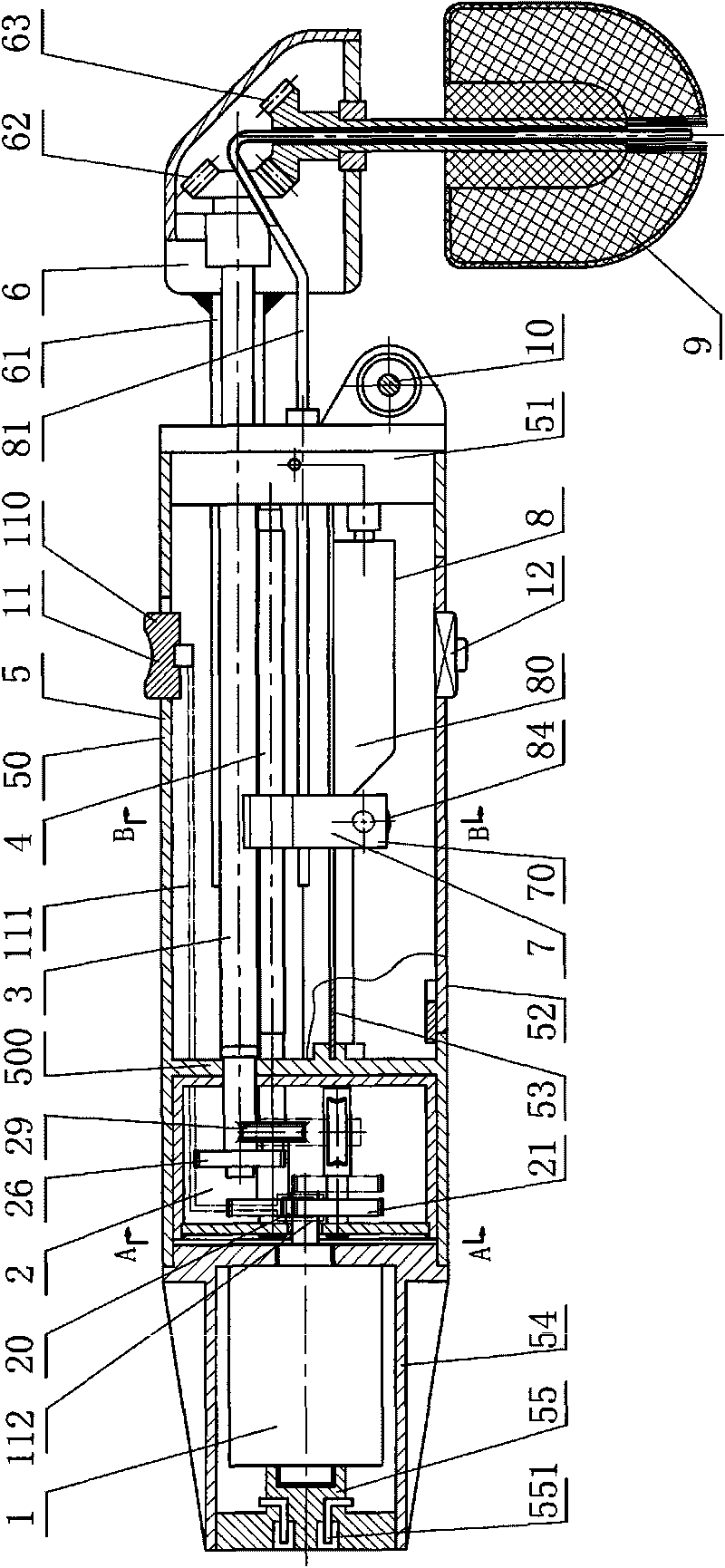

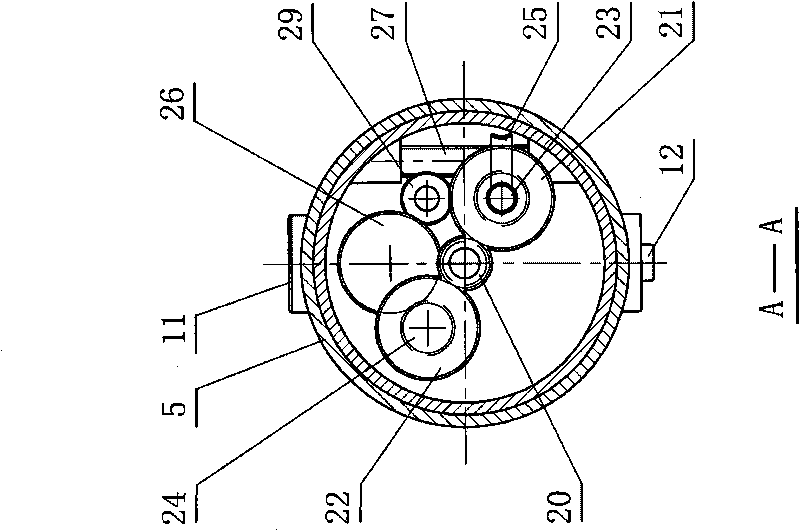

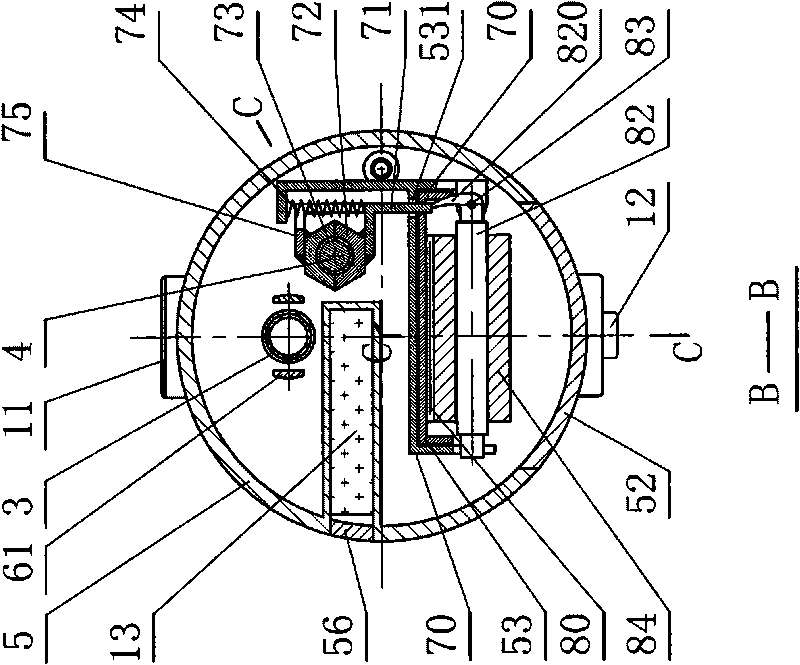

[0047] Attached below Figures 1 to 27 The embodiment of the present invention is further described:

[0048] figure 1 , 2 , 3, indicate the overall structural layout of the embodiment of the present invention. The housing 5 in the figure includes a main housing 50 , a terminal body 51 , a lower cover 52 , a slot plate 53 , a rear seat 54 , a rear plug 55 , and a side cover 56 . The motor 1 and the transfer case 2 are sequentially installed in the casing 5 from left to right, the output shaft of the motor 1 is connected to the input end gear 20 of the transfer case 2; the right end of the transfer case 2 is provided with the first output end gear 26 and the second output end worm gear 29, the first output end gear 26 is power connected with the transmission shaft 3, the right end of the transmission shaft 3 is power connected with the bevel gear 62 in the connector 6, and then the power is output through the bevel gear 63, the bevel The rotating shaft of shaped gear 63 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap