Equipment for manufacturing woven and wound high-strength composite material

A high-strength composite material and equipment technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of bending, low strength, and easy to be corroded at the support joint, and achieves integrity and fatigue resistance. Good, avoid waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

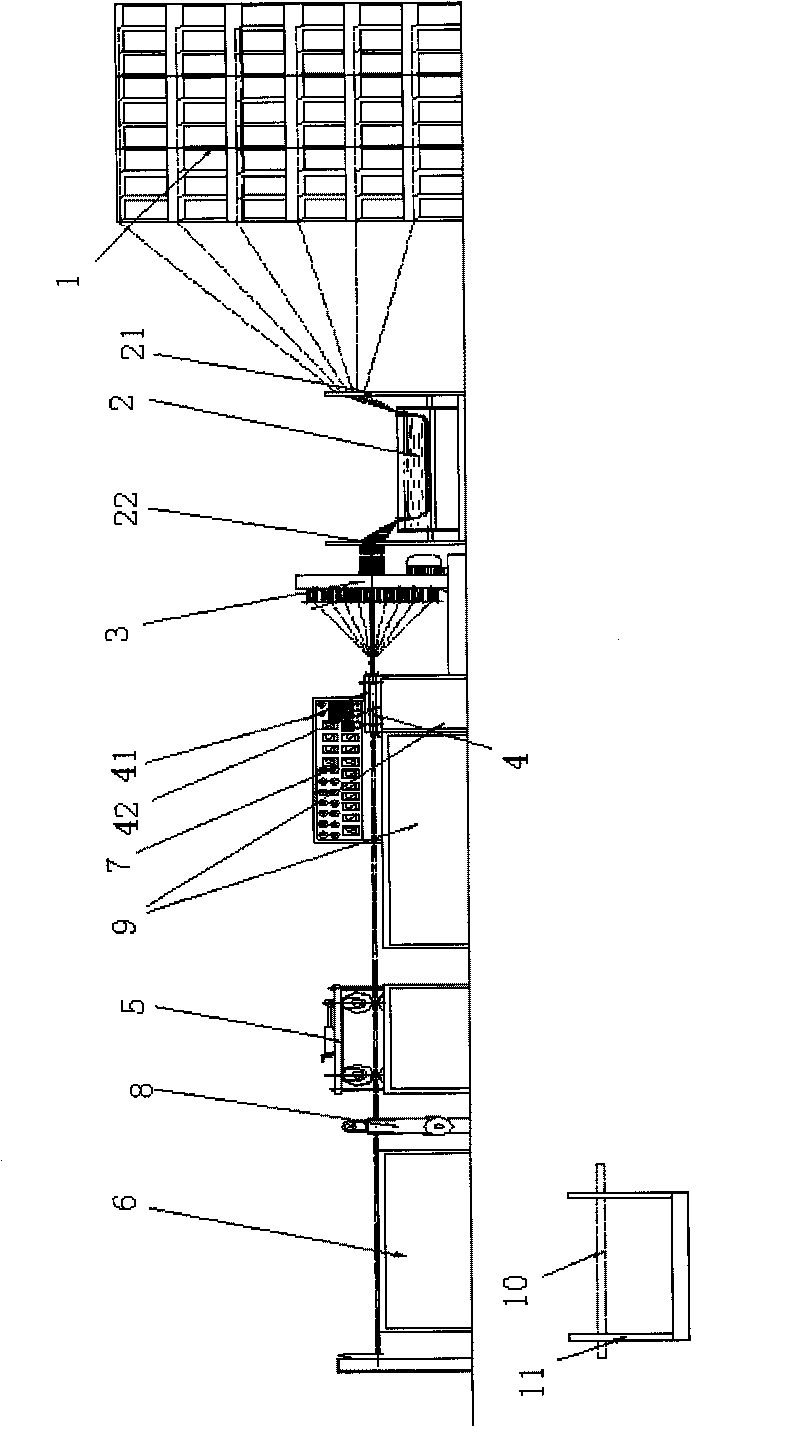

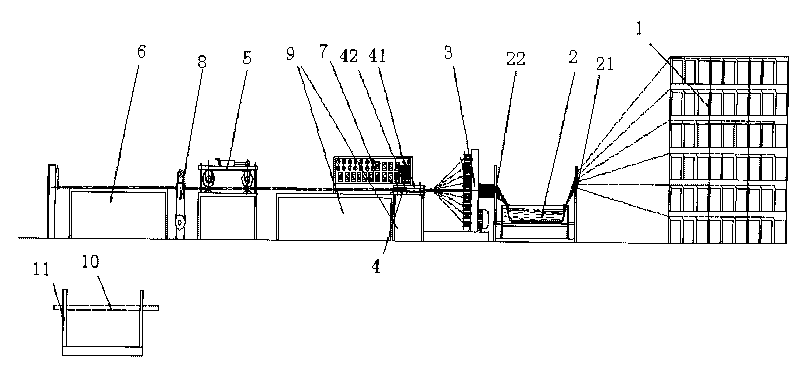

[0011] An equipment for manufacturing braided and wound high-strength composite material tubes, the equipment includes a creel 1, a glue tank 2, a weaving machine 3, a pultrusion die 4, a tractor 5, a material receiving frame 6, an electric control cabinet 7 and a feeding machine 8 . The glue groove 2 is arranged on the yarn outlet end of the creel 1, and the two sides of the glue groove 2 are respectively provided with a front threading creel 21 and a rear threading creel 22, and the front end of the knitting machine 3 is connected with the rear threading creel 22, and the knitting machine The rear end of 3 is connected with pultrusion die 4. An upper heating plate 41 and a lower heating plate 42 are provided in the pultrusion die 4 . The tractor 5 is arranged at the rear end of the pultrusion die 4; the receiving frame 6 is arranged at the rear end 6 of the pultrusion die, and a blanking machine 8 is arranged between the material receiving frame 6 and the tractor 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com