Ink band box and recording apparatus

A technology of recording device and ink ribbon cassette, applied in the directions of ink ribbon cassette, inking device, printing, etc., can solve the problem of damage to the ink ribbon, etc., and achieve the effect of stable extraction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

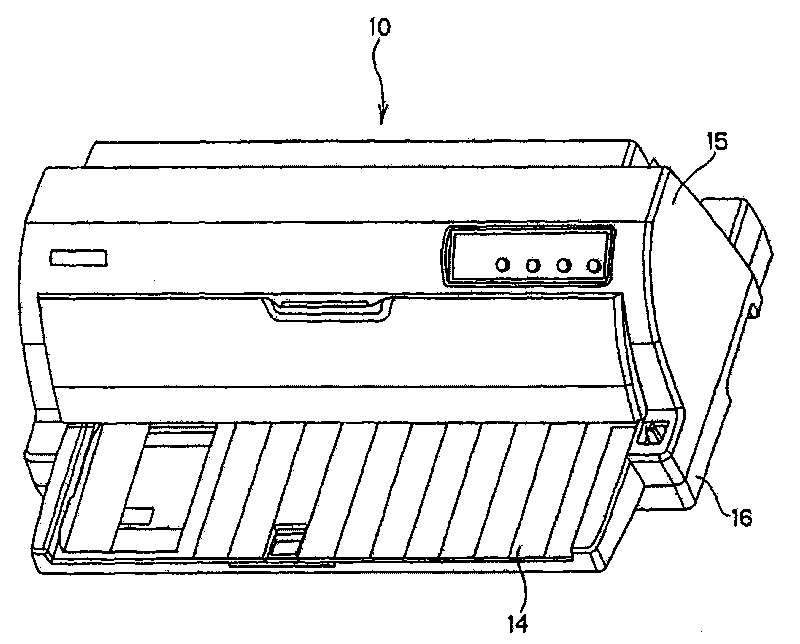

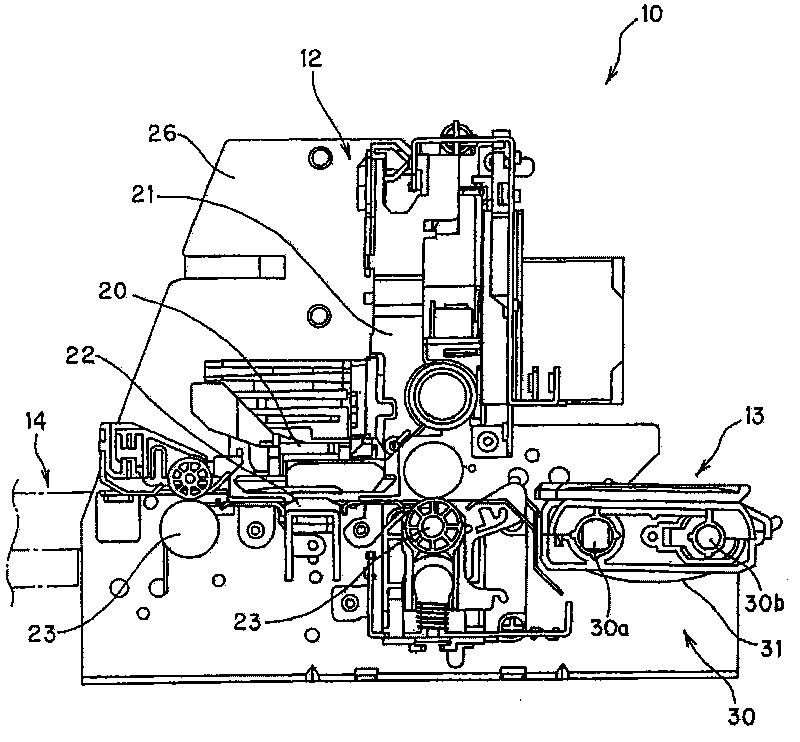

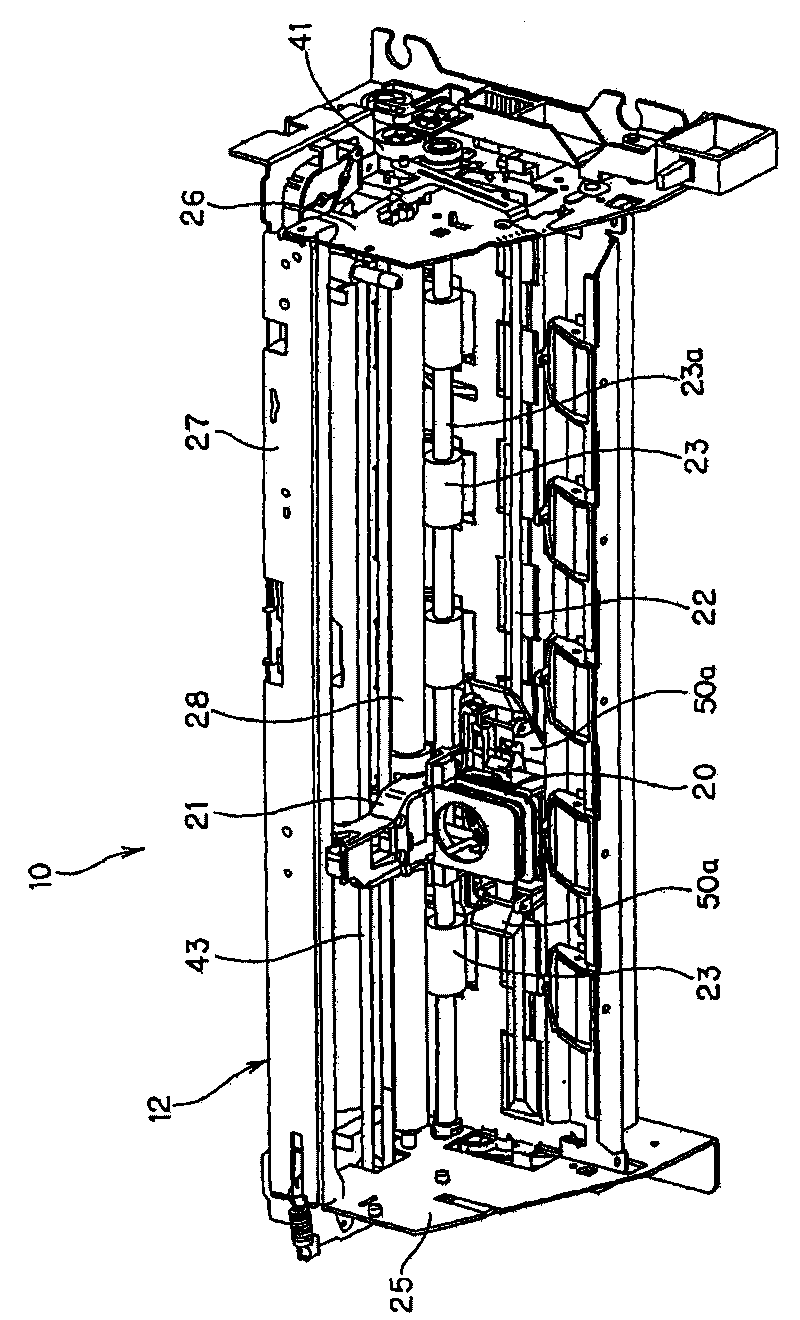

[0042] figure 1It is a perspective view showing the appearance of the front of the printer 10 to which the ink ribbon cassette according to the embodiment of the present invention is applied, figure 2 is a side sectional view showing the printer 10 . image 3 It is a perspective view showing the frame structure of the printer 10 .

[0043] The printer 10 is a serial dot matrix printer having a recording head 20 that selectively drives a plurality of recording wires and a carriage 21 on which the recording heads 20 are mounted. An image including characters is recorded on a recording medium (hereinafter referred to as a sheet).

[0044] Such as figure 2 As shown, if the printer 10 is roughly distinguished, it includes: a printer main body 12 constituting a recording unit, a transport unit 13, a sheet guide 14, and as figure 1 As shown, their top and bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com