Measurement of wheel and/or axle load of road vehicles

A flexible, metal plate technology for applications in the field of dynamic weighing instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

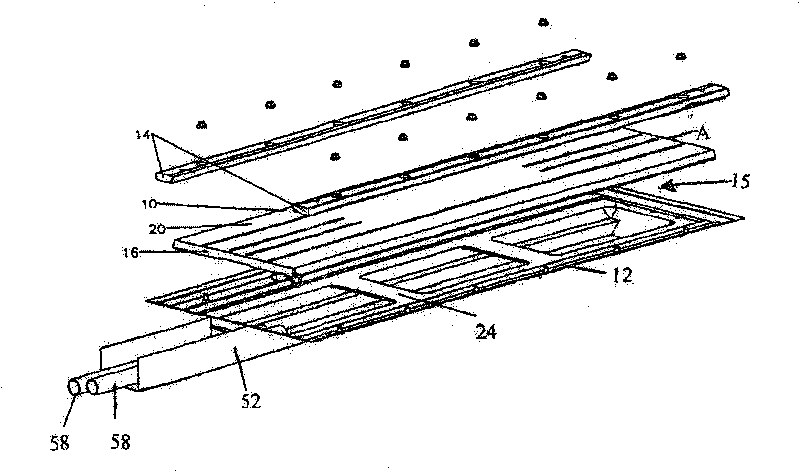

[0037] figure 1 description of

[0038] Such as figure 1As shown, the dynamic weighing instrument 10 of one embodiment of the present invention includes a substantially cuboid frame 12 including means, such as vertical mounting arms 14, to secure the frame 12 to a road surface (not shown). out). The flexible deformable sheet system 20 (so-called BENDING PLATE TM SYSTEM) is also basically in the shape of a cuboid. It will be described in more detail below. This view shows the upper flexibly deformable metal plate 16 , the lower or bottom metal plate 24 , the conductive wires or cables 58 and the longitudinally extending channel 52 .

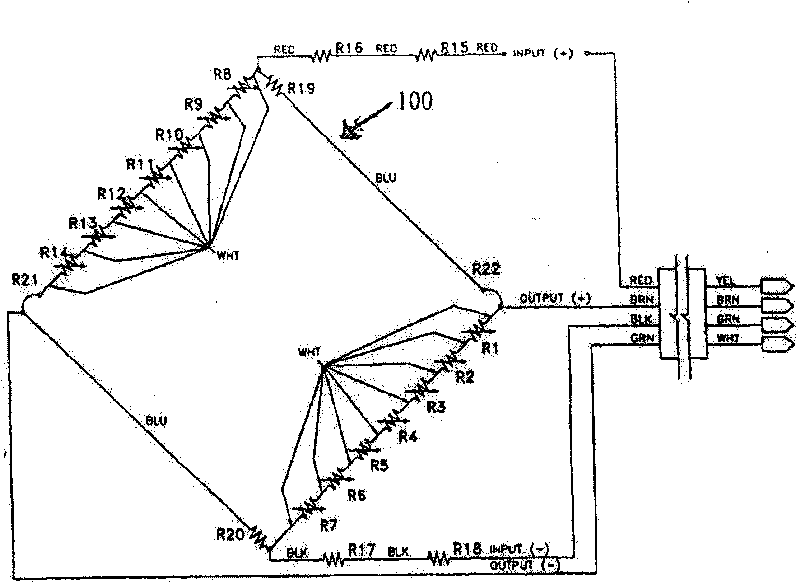

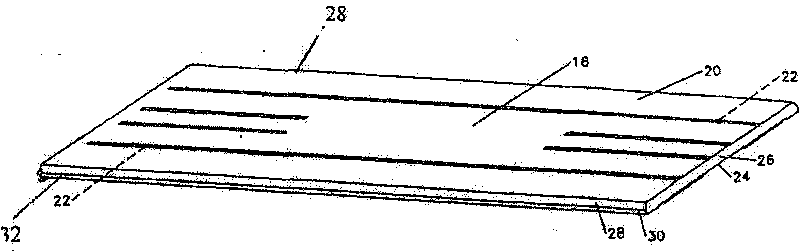

[0039] figure 2 , image 3 and Figure 4 description of

[0040] Such as figure 2 , image 3 and Figure 4 As shown, a flexibly deformable sheet system 20 of one embodiment of the present invention is embedded in substantially cuboid-shaped plates 16, 24 with a hollow and narrow space or volume 15 therebetween (eg, figure 1 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com