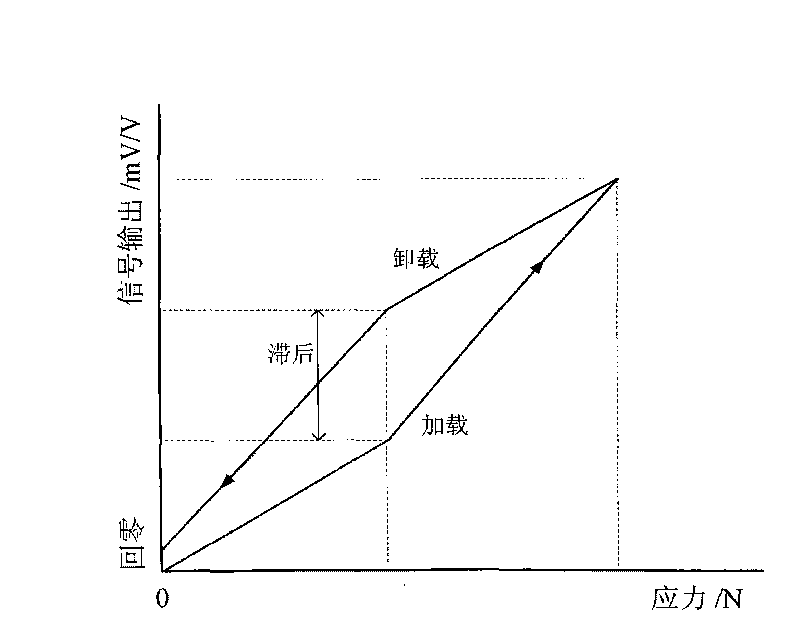

Method for reducing lag of ferromagnetic elastomer of weighing sensor

A weighing sensor and ferromagnetic technology, which is applied in the testing/calibration of weighing equipment, weighing equipment and instruments using elastically deformable parts, etc., to achieve the effects of reducing manufacturing costs, improving weighing accuracy, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

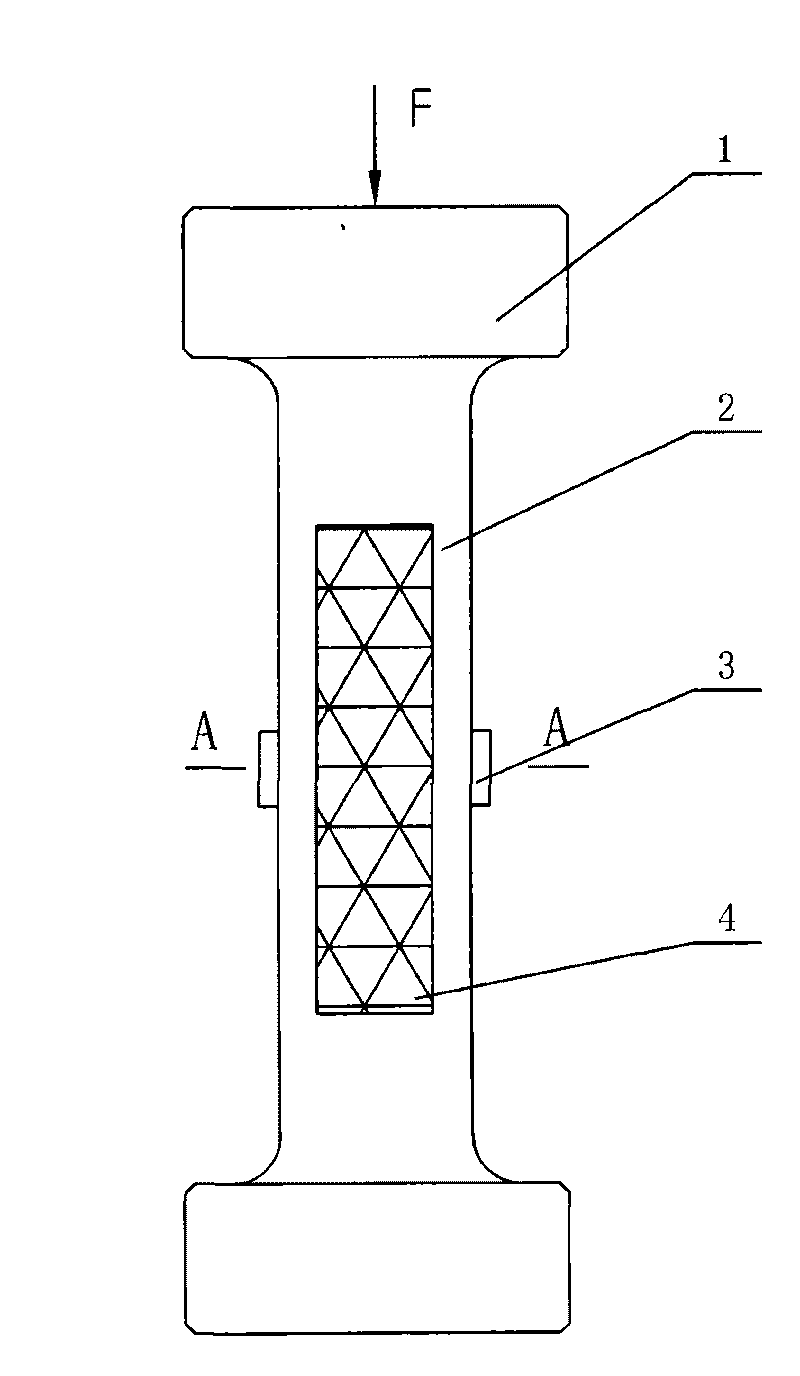

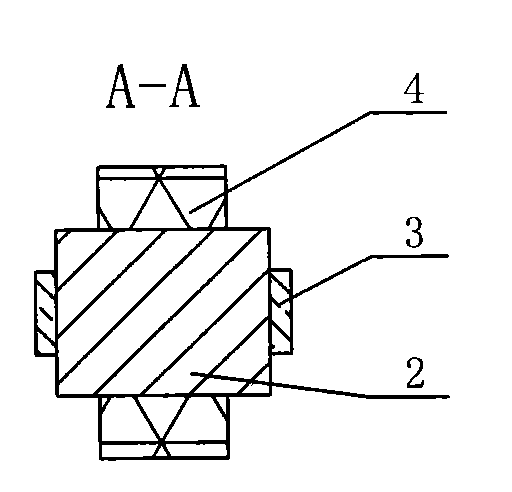

[0027] The method for reducing the hysteresis of the ferromagnetic elastic body of the load cell in the present invention firstly makes the ferromagnetic elastic body 1 into the required shape through machining and heat treatment, such as figure 2 , 3 The cylindrical ferromagnetic elastomer shown in the figure can be made by 17-4PH. The dimensions of the column ferromagnetic elastic body are 100-200mm×15-20mm×15-20mm in length, width and height, and the strain gauge 3 is fixed on the iron At the sensitive beam 2 of the magnetic elastic body, the strain gauge 3 can be pasted on the sensitive beam 2 in a conventional manner, and magnetic bodies 4 are respectively fixed on the opposite sides of the sensitive beam 2 of the ferromagnetic elastic body 1, and the two sides The magnetic body 4 forms a magnetic field in the same direction, that is, N poles or S poles are arranged in the same direction, and the direction of the magnetic field is parallel to the length direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com