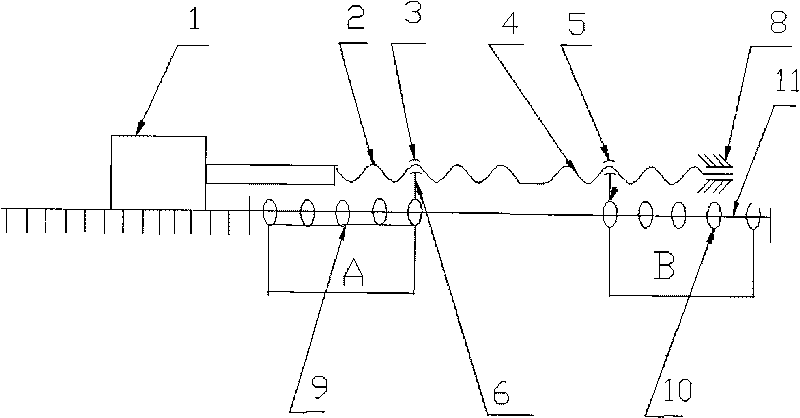

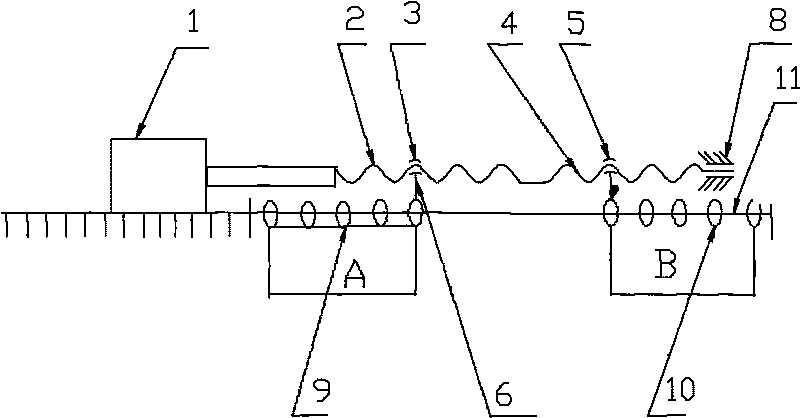

Electric spiral curtain machine

A technology of electric spiral and curtain machine, which is applied in the field of spiral curtain machine and electric spiral curtain machine, which can solve the problems of troublesome installation and maintenance, complicated mechanism, and easy failure, and achieve the effect of saving precious metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Choose steel wire or iron wire with certain mechanical properties, and make left-hand helical wire (2) and right-helical wire (4) with different rotation directions from the middle part, install one end in the bearing seat (8), and connect the other end with the motor drive shaft. Fix, respectively install the left nut (3) and the right nut (5) on the left helical wire (2) and the right helical wire (4), and both pass the left hanging wire (6), the right hanging wire (7) and the left Ring (9), right ring (10) link to each other, and ring is sleeved on the guide wire (11), so, when motor rotates by different directions, just can drive curtain A, B to realize the action of opening and closing. If it is a single-sided curtain, it only needs to use the screw thread in the same direction, and match other parts accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com