Installation mechanism of closestool cover plate

The technology of an installation mechanism and a toilet cover, which is applied in the field of sanitary ware, can solve the problems of difficulty in dismounting the toilet cover, high cost, complicated installation mechanism, etc., and achieves the effects of quick assembly and disassembly, avoiding shaking, and being convenient to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

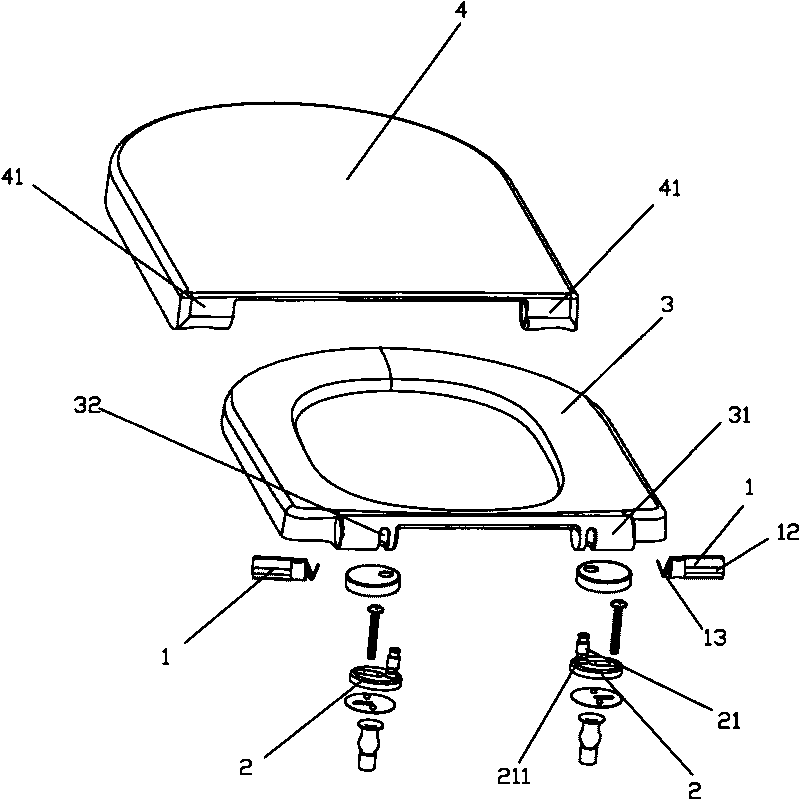

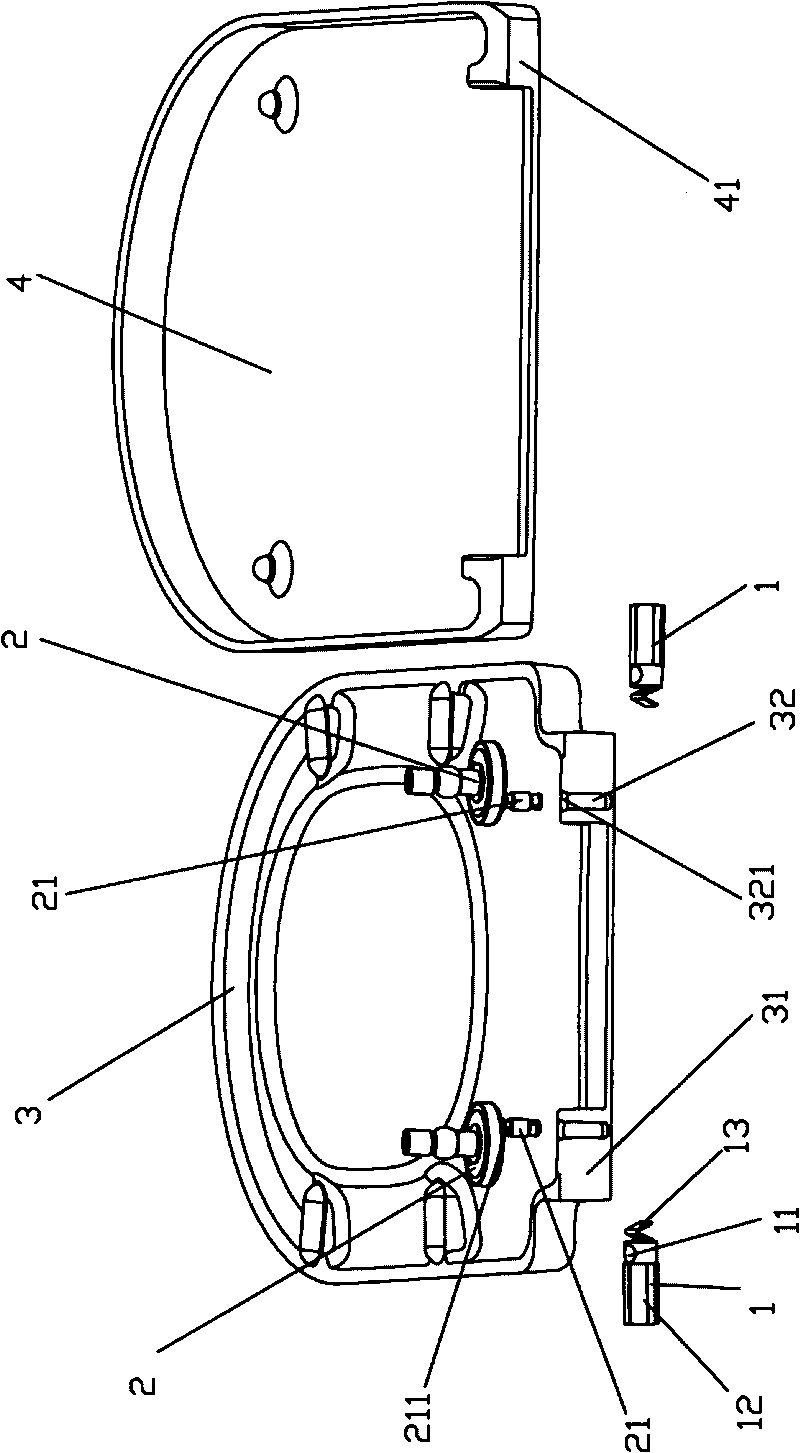

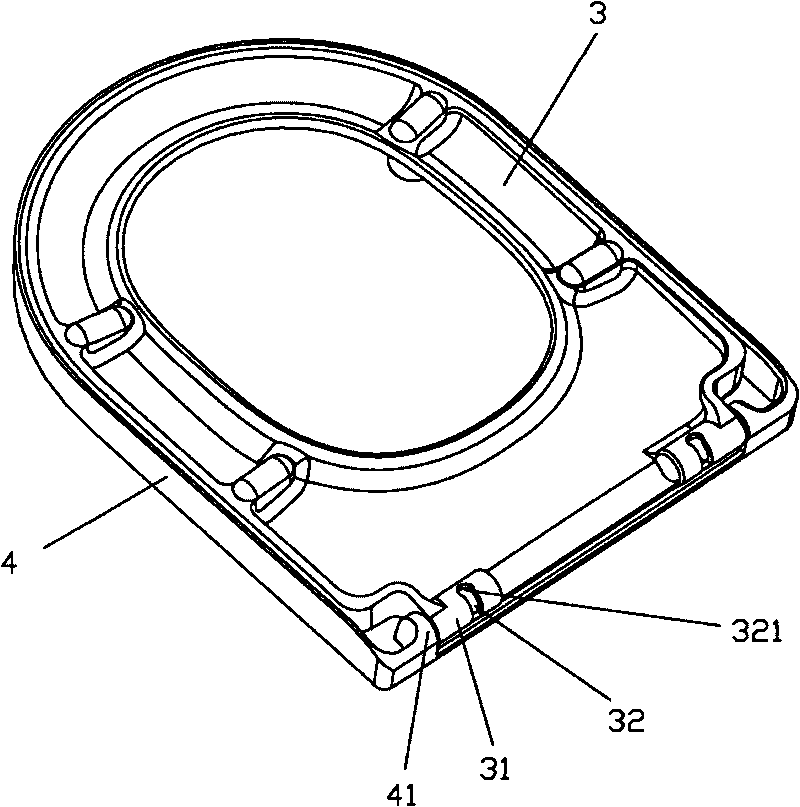

[0032] Referring to the accompanying drawings, a toilet cover installation mechanism of the present invention is used to install the toilet cover on the toilet seat (not shown in the figure), so that the toilet seat 3 of the toilet cover and the toilet Cover 4 can be turned over with respect to the toilet seat body, such as the toilet upper cover 4 of the toilet cover is lifted or covered, or the toilet seat 3 of the toilet cover is lifted or covered, or the toilet seat of the toilet cover is lifted or covered. Actions such as seat ring 3 and toilet loam cake 4 are set off together or cover under.

[0033] Usually, the installation mechanism of the toilet cover needs two sets, and the two sets are symmetrical structures.

[0034] A convenient assembly and disassembly installation mechanism of the toilet cover of the present invention comprises a rotating shaft 1 for providing the toilet cover to rotate around it, a support 2 for fixing the rotating shaft and a rotating shaft s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com