Thread tension device

A tensioning device, yarn technology, applied in the direction of transportation and packaging, thin material handling, conveying filamentous materials, etc., can solve problems and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

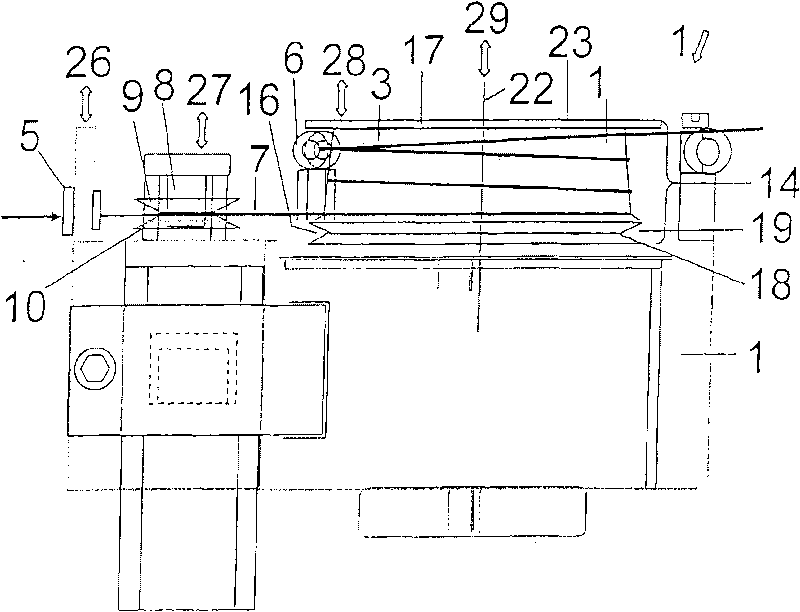

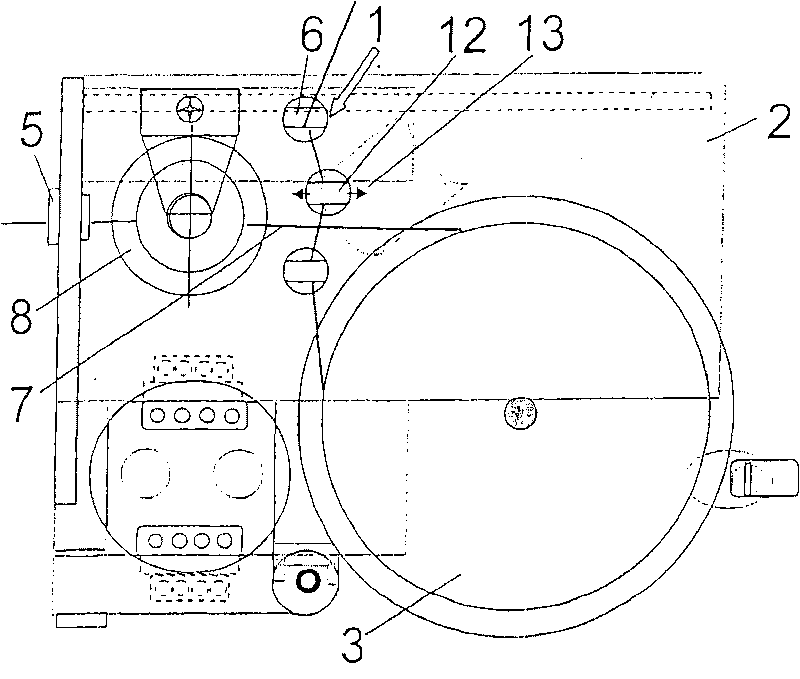

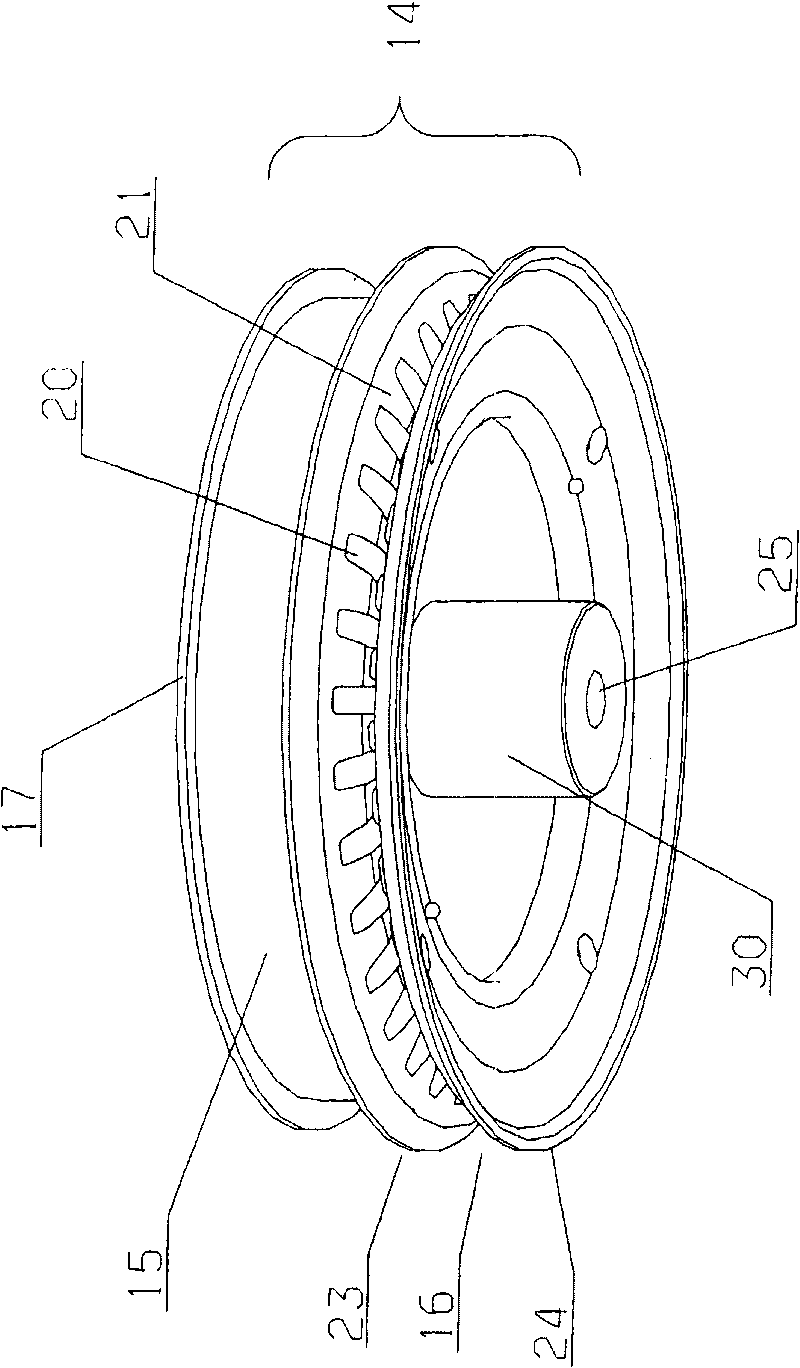

[0021] figure 1 The yarn tensioning device 1 is shown, which has a base 2 on which the bobbin 3 is rotatably supported. The bobbin 3 can be connected to the motor 4 in a torsion-resistant manner, and the motor 4 can also be operated by a generator.

[0022] The base 2 is provided with a lead-in part 5 and a lead-out part 5.

[0023] The yarn 7 passes through the lead-in 5 and is wound around the bobbin 3, and then passes through the lead-out 6. A stabilizing device 8 is provided between the lead-in 5 and the bobbin 3, which consists of two discs 9, 10 designed in a conical shape, which are stacked on top of each other with their smaller diameters. The stabilizing device 8 attenuates vibrations in the yarn 7, which may be caused, for example, by drawing the yarn 7 through the head from a loop not shown in detail.

[0024] A yarn guide 11 with a movable yarn guide 12 is arranged between the bobbin 3 and the lead-out member 6. The yarn guide 12 can move in the direction of the double ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com