Thread tension device

A tensioning device, yarn technology, used in transportation and packaging, thin material handling, transportation of filamentous materials, etc., can solve problems such as problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

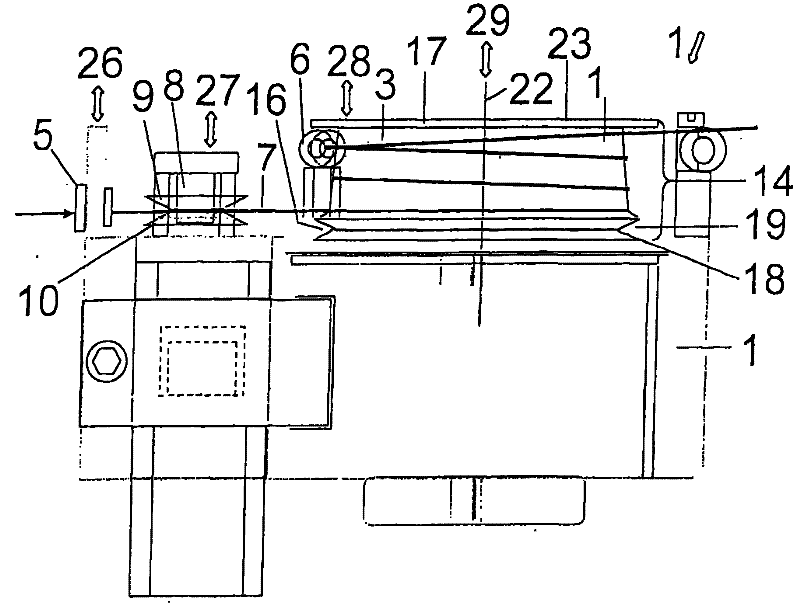

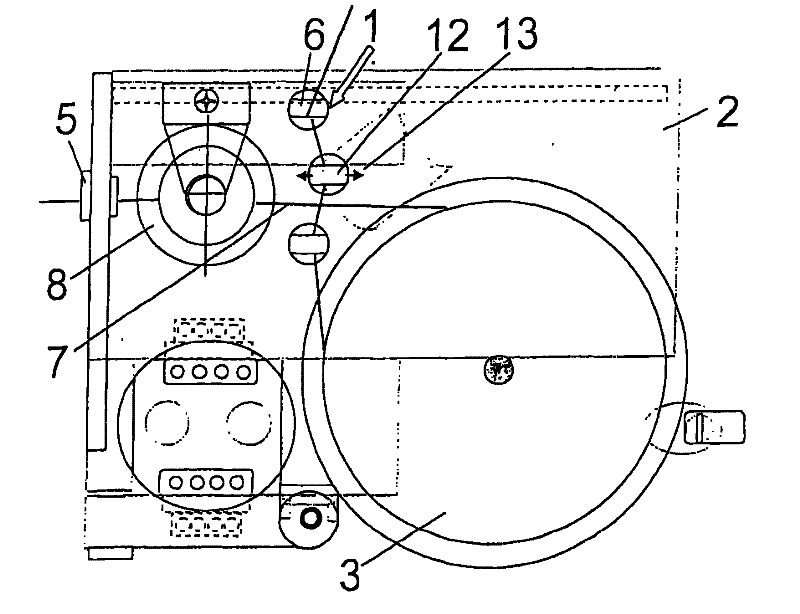

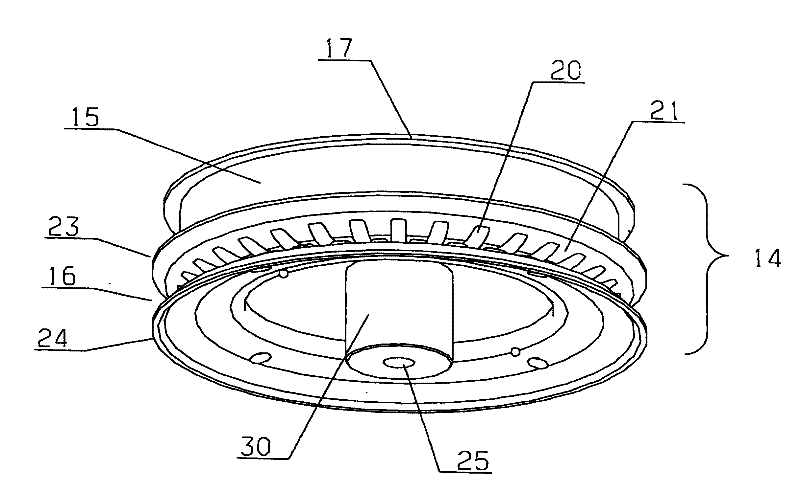

[0021] figure 1 A yarn tensioning device 1 is shown, which has a base 2 on which a bobbin 3 is rotatably mounted. The bobbin 3 can be connected in a rotationally fixed manner to an electric motor 4 which can also be operated as a generator.

[0022] On the base 2 there are lead-in parts 5 and lead-out parts 5 .

[0023] The yarn 7 is passed through the inlet 5 and wound around the bobbin 3 and then through the outlet 6 . Between the insertion part 5 and the bobbin 3 there is a securing device 8 which consists of two conically shaped disks 9 , 10 which are placed one above the other with their smaller diameters. The stabilizing device 8 dampens vibrations in the yarn 7 which may be caused, for example, by withdrawing the yarn 7 through the head from the coil, which is not shown in detail.

[0024] Arranged between the bobbin 3 and the withdrawal part 6 is a yarn guide 11 with a movable yarn guide 12 which is movable in the direction of the double arrow 13 , that is to say su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com