Dacron simulation crepe yarn process

A simulation and crepe technology, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of immaturity, and achieve the effect of rich style, good hand feeling and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

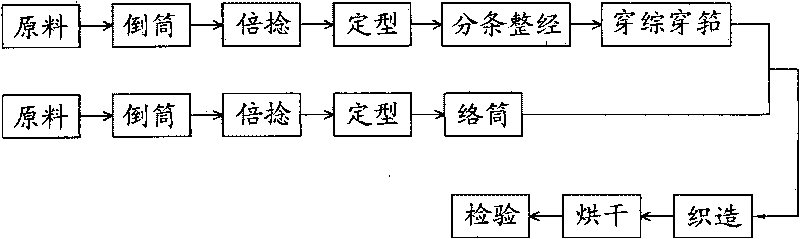

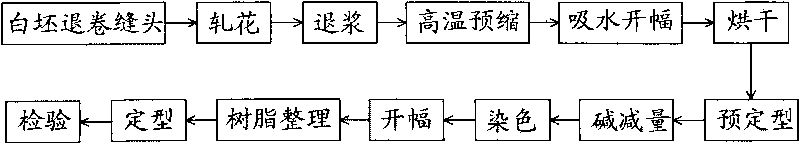

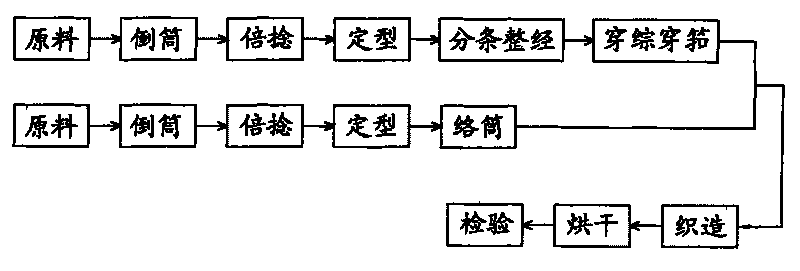

[0017] combine figure 1 and figure 2 , the present invention will be described in further detail.

[0018] 1. Weaving process:

[0019] The three raw materials 167dtex polyester filament 900 twist / ms, 167dtex HOY 900 twist / ms, 150dtex rayon 600 twist / ms are composed according to the ratio of 56:24:1. One gold wire is added in each combination cycle, the mass percent content is 3.4%. After being combined and arranged in the warp direction, the steps of rewinding, two-for-one twisting, shaping, section warping, drawing in and reeding are sequentially performed. After being combined and arranged in the weft direction, the steps of rewinding, two-for-one twisting, shaping and winding are followed in turn. Among them, the two-for-one twist coefficient of warp and weft is 2500. Then it is woven by a water-jet loom. During weaving, the warp yarn is 34 yarns / cm, and the weft yarn is 20 yarns / cm. Finally, the cloth is dried and inspected.

[0020] Wherein, during weaving, in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com