Conveniently-detached floating rotary shaft seal

A technology for sealing and sealing the main body of the rotating shaft, which is applied to the sealing of the engine, non-variable-capacity pumps, engine components, etc., can solve the problems of difficult maintenance and unloading, poor sealing performance of the rotating shaft seal, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

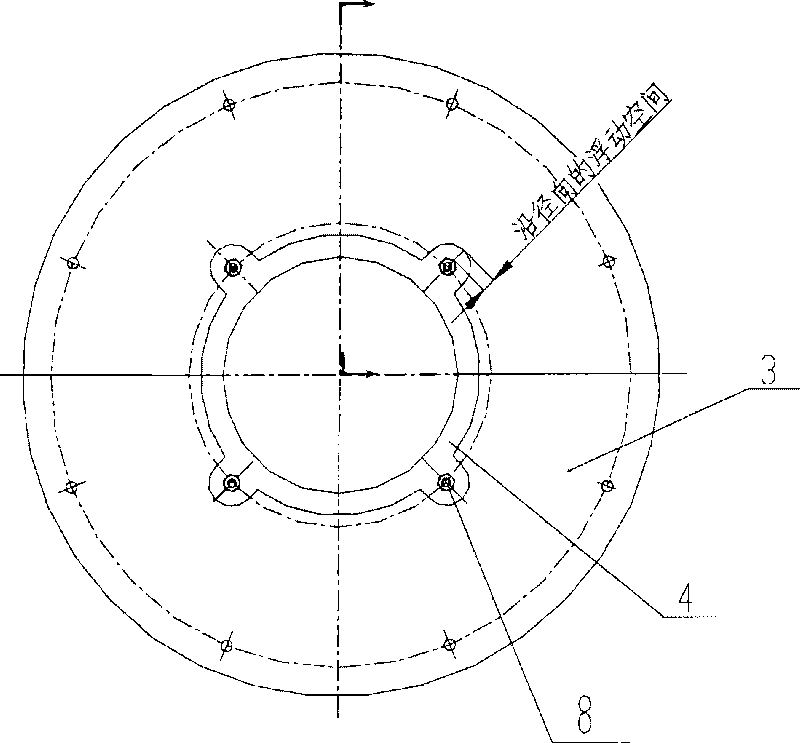

[0010] figure 1 It includes a pressure plate 3, a sealing body combination 4, and connecting bolts and nuts 8, and is characterized in that: the pressure plate 3 is provided with a plurality of semi-arc grooves, and the protruding connecting bolts and nuts 8 on the sealing body combination 4 are embedded in the semi-arc grooves;

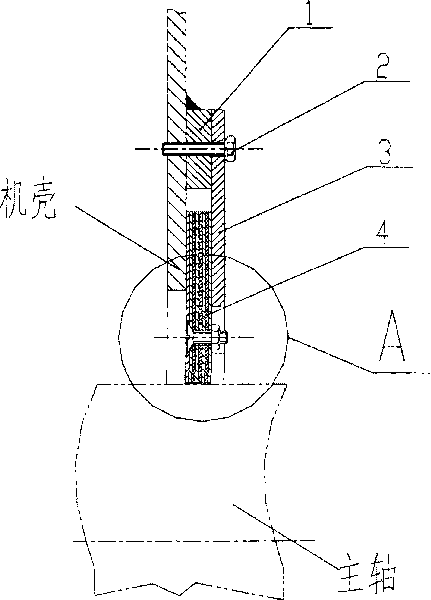

[0011] figure 2 It includes a floating space forming plate 1, fixing bolts 2, a pressure plate 3, and a sealing body combination 4, and is characterized in that: the sealing body combination 4 is in the cavity formed by the casing, the floating space forming plate 1, and the pressure plate 3;

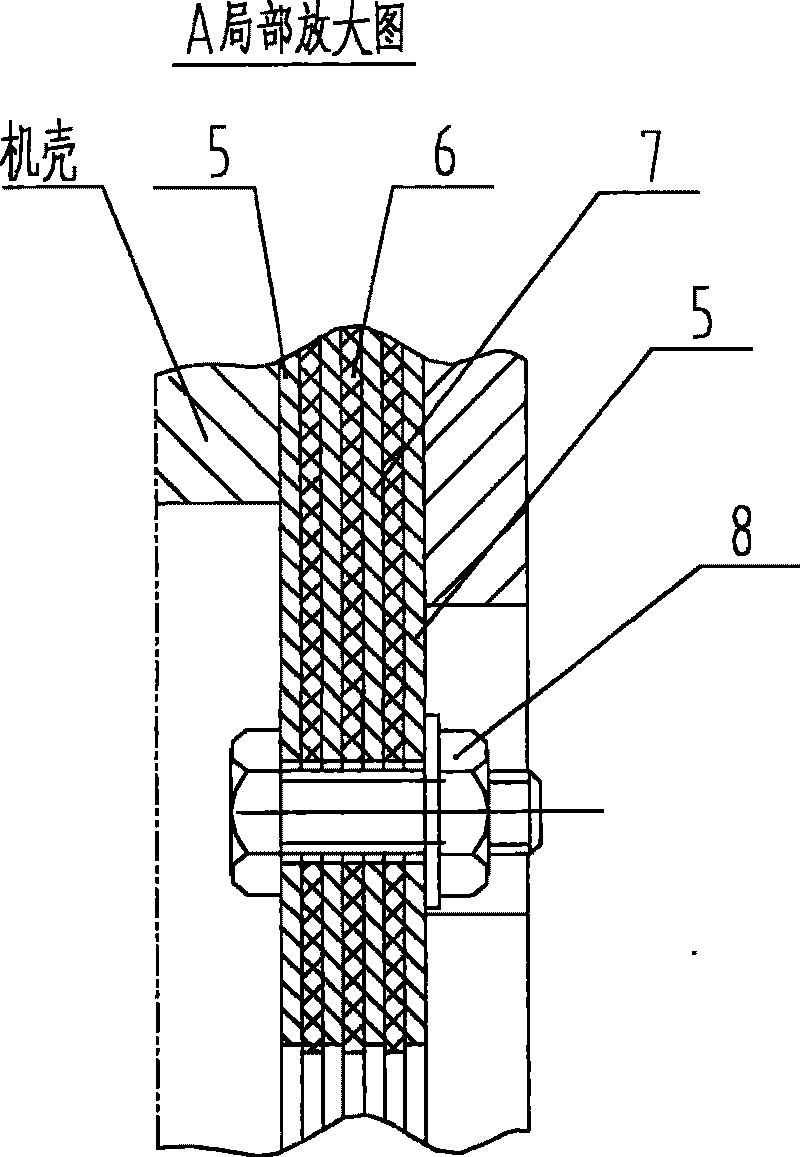

[0012] image 3 It includes a thin iron plate 5, a sealing material 6, an aluminum plate 7, and connecting bolts and nuts 8, and is characterized in that: the sealing material 6 and the aluminum plate 7 are divided in half, crossed and overlapped, and arranged in multiple layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com