Installation method of annular heating furnace equipment

An annular heating furnace and installation method technology, applied in the field of installation, can solve the problems of being easily affected by external factors, slow measurement speed, poor stability, etc., and achieve the effect of reducing technical capability requirements, saving installation time, and reducing external factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

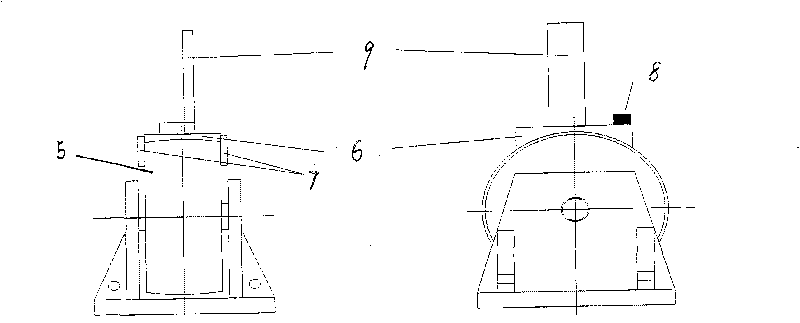

[0031] An installation method of an annular heating furnace equipment is carried out according to the following steps:

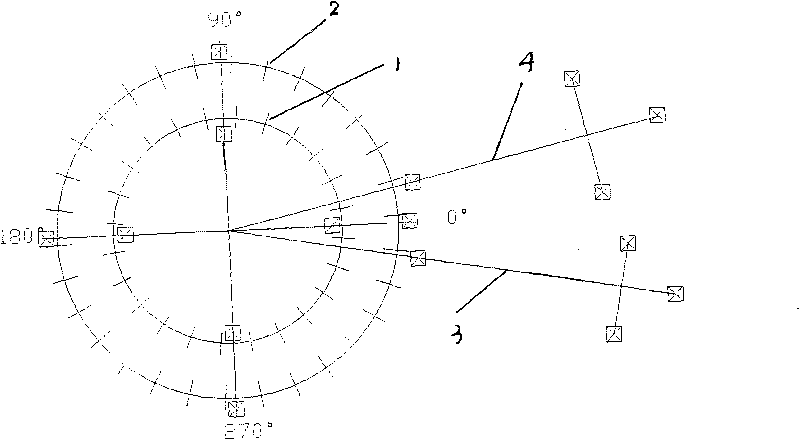

[0032] 1. Center point setting. (Such as figure 1 shown)

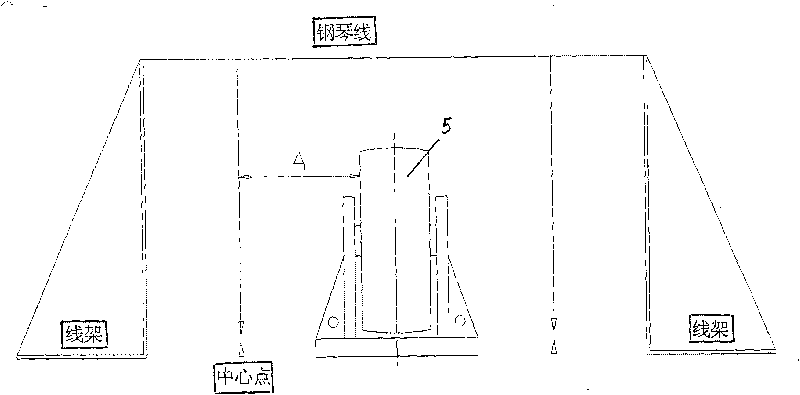

[0033] A platform for measurement is set at the center of the annular furnace. The platform is poured with reinforced concrete. A round hole with a diameter of 200mm is reserved in the center of the platform so that the central point of the annular furnace on the ground can be seen from the platform. It is advisable that the height of the platform can be easily measured by the backup roller and sector after the total station is set up.

[0034] First, set the control lines of 0°, 90°, 180°, and 270° of the ring furnace on the basis of the ring furnace. Based on these four control lines, use the total station to set the center of the inner and outer ring support rollers. Line 1, 2, the distance from the endpoint of the center line to the center of the furnace must be a fixed value. At the same tim...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap