Fatigue test stand of automobile pedals

A technology of fatigue test and automobile pedal, which is applied in vehicle test, impact test, machine/structural component test, etc., to achieve the effect of accurate experimental data, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described below in conjunction with embodiment and accompanying drawing.

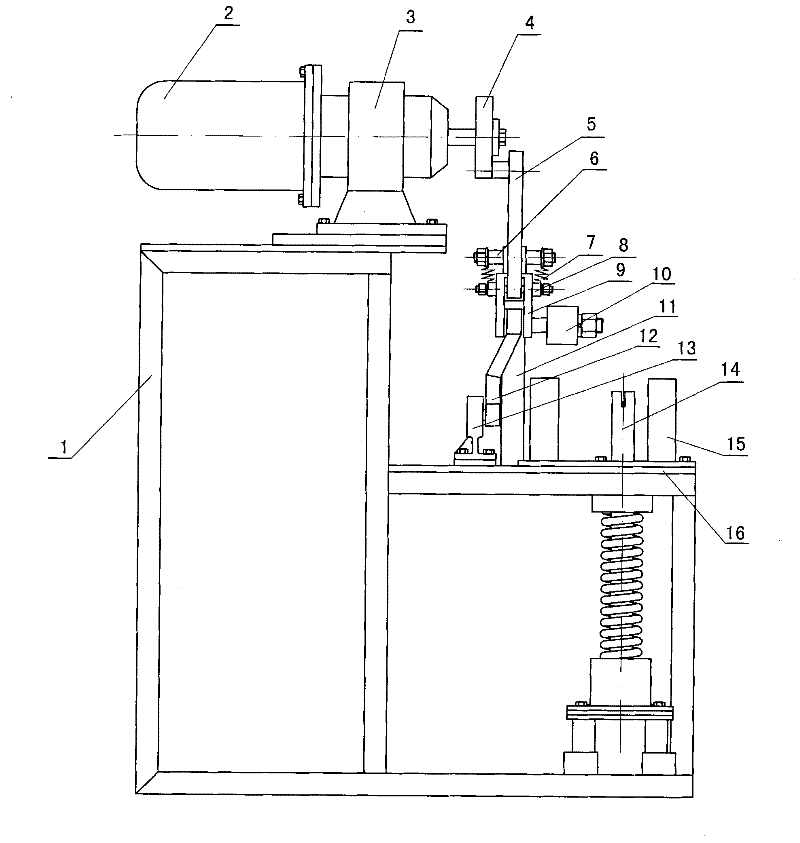

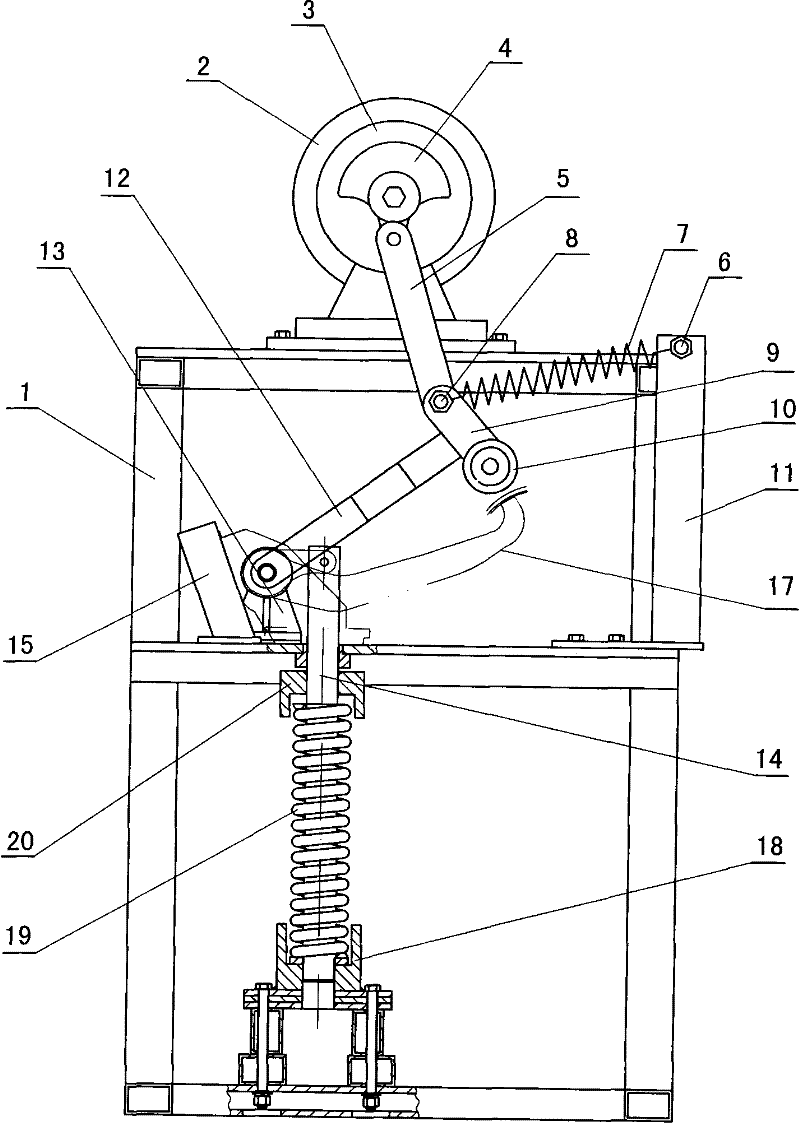

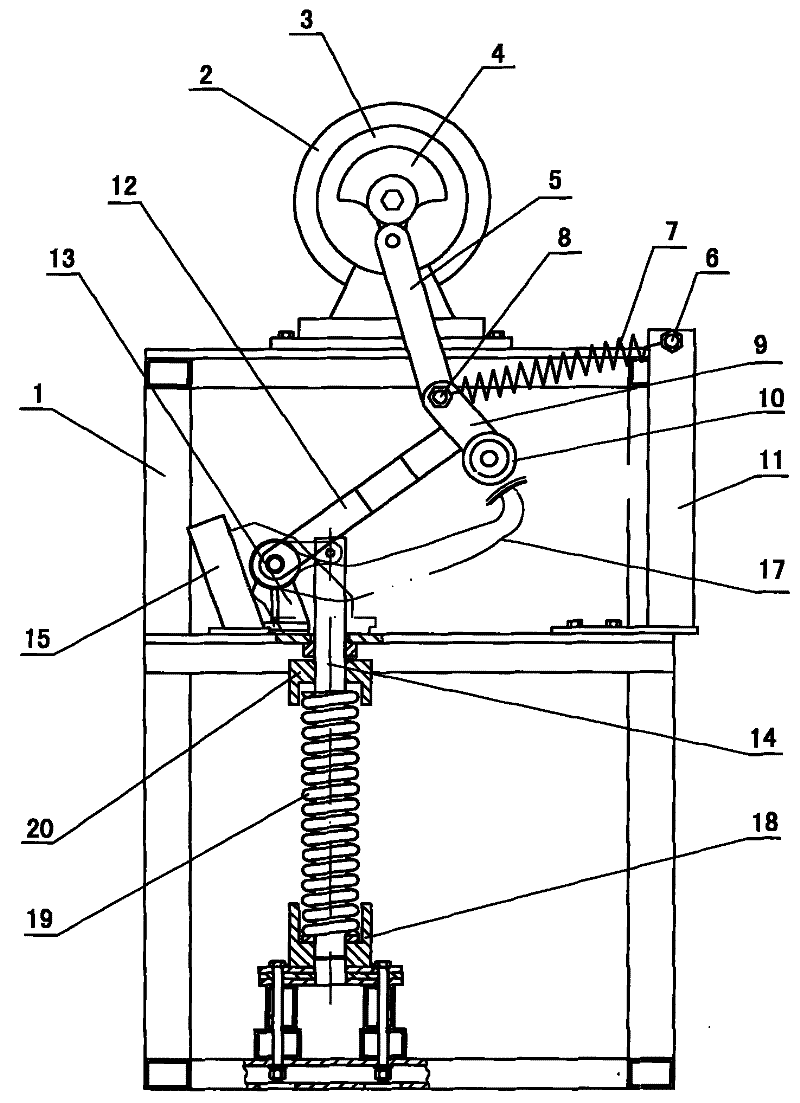

[0013] see figure 1 , figure 2

[0014] The motor 2 provided on the frame 1 of the automobile pedal fatigue test bench is connected with the reducer 3, the output shaft of the reducer 3 is connected with the eccentric wheel 4, the eccentric wheel 4 is hinged with one end of a connecting rod 5, and the working table 16 is located below the speed reducer 3, and a support 13 is fixed on the workbench. One end of a rocker 12 is hinged to the support 13, and the other end of the rocker 12 is connected to a connecting block 9, and the connecting block 9 is connected to the connecting rod. The other end of 5 is hinged, and roller 10 is housed on the connecting block 9 . A pillar 11 is fixed on the workbench 16 , and a spring 7 is connected between the connecting block 9 and the pillar 11 . A pin shaft 14 passes through the workbench 16 . A pair of support frames 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com