Multipurpose wheel disc tester

A tester and multi-purpose technology, applied in gas turbine engine testing, instrumentation, engine testing, etc., can solve the problems of comprehensive environment, damage, fatigue, etc. without simulating the working environment of the roulette wheel, and achieve thermal shock and load testing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the embodiments of the drawings.

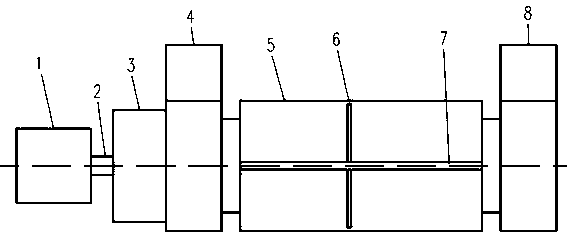

[0011] figure 1 As shown, the multi-purpose wheel tester includes 1-motor, 2-coupling, 3-gear box, 4-intake volute, 5-test chamber, 6-test wheel, 7-support shaft, 8 -Exhaust volute. 1-The motor is connected to the 3-gear box through the 2-coupling, the 3-gear box is connected to the 7-support shaft, the 4-inlet volute is located between the 2-gear box and the 5-test chamber, and the 6-test wheel The disc is located in the 5-test chamber, and the 8-exhaust volute is located behind the 5-test chamber. 6-The test wheel is made of high temperature resistant titanium alloy.

[0012] Operation mode: Driven by 1-motor 2-gear box, transfer the required speed to test 7-support shaft and 6-test wheel, the gas enters 5-test chamber through 4-inlet volute, and the load (pressure , Temperature) is transferred to the 6-test wheel, the gas is finally discharged through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com