Connecting plate for replacing 220kV double bundle conductor strain insulator with centricity and method thereof

A technology of double-split conductors and tensile insulators, which is applied to the suspension devices of cables, overhead lines/cable equipment, etc., can solve the problems affecting the normal operation of transmission lines, and there is no live replacement of 220kV double-split conductors. Time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

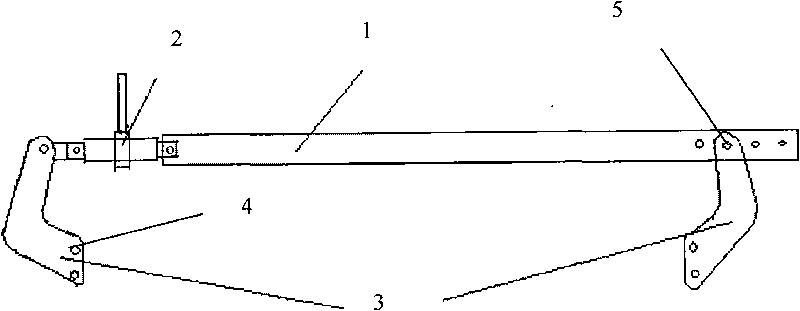

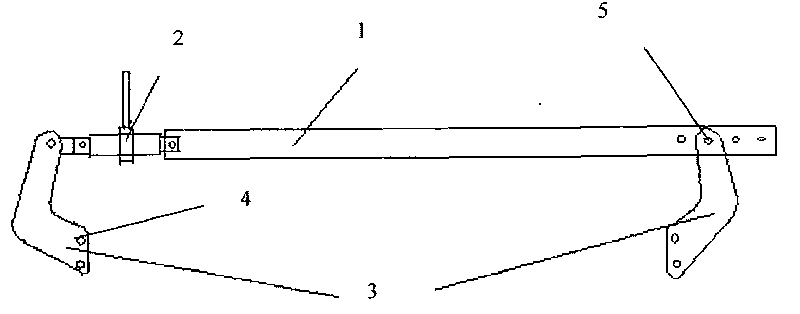

[0018] Such as figure 1 As shown, the present invention includes a tie plate 1 and a screw 2 connected to each other in a transverse direction; an opposite connecting plate 3 is symmetrically installed on the outer ends of the pulling plate and the screw mandrel, and a connecting hole 4 is provided at the free end of the connecting plate. The connecting plate 3 is an L-shaped connecting plate, one end of which is connected with the pull plate by a screw 5, and the other end is provided with a connecting hole 4. The pull plate 1, the screw mandrel 2 and the connecting plate 3 are all insulators.

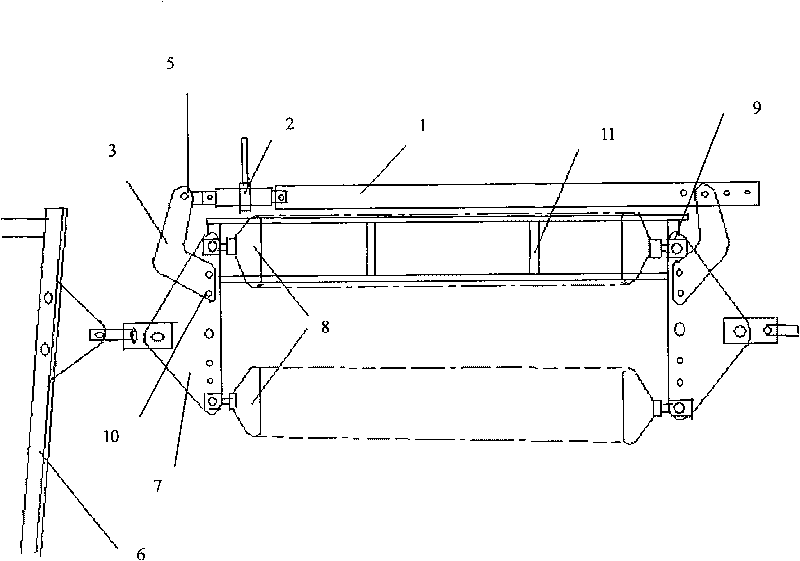

[0019] Such as figure 2 As shown, on the cross arm 6 of the power tower, a two-joint plate 7 with a set of mounting holes 10 is installed through components, and an insulator 8 is installed on the two-joint plate, and the insulator 8 is installed on the two-joint plate 7 through an insulator pin 9 . When the insulator 8 needs to be replaced, proceed as follows:

[0020] (1) The el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com