Elastomer loudspeaker box system

A stereo speaker and speaker box technology, applied to sensors, sensor parts, frequency/direction characteristic devices, etc., can solve problems such as interference, low-frequency sound turbidity and clarity, and achieve the goal of improving low frequency, improving purity, and increasing volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

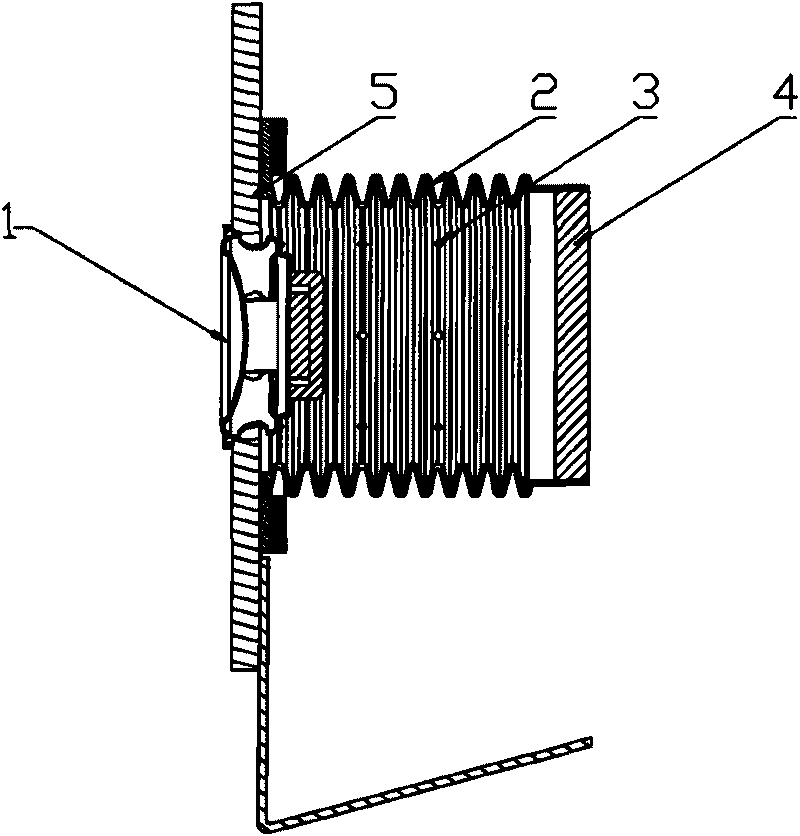

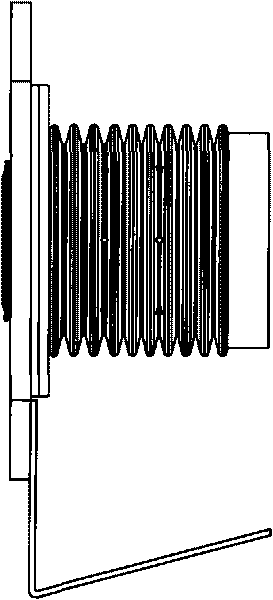

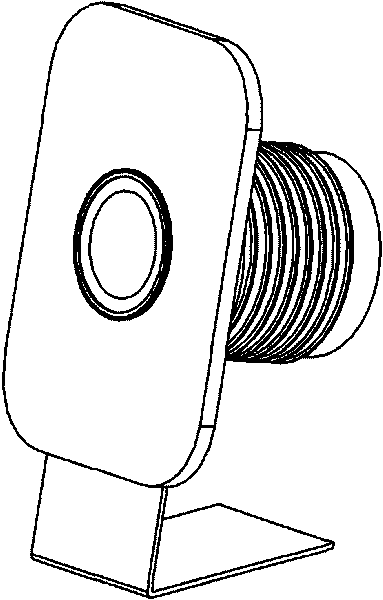

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the elastomer speaker box system includes a speaker unit 1, a speaker box 2, a bottom plate 4, and a baffle 5. The speaker box 2 is made of a corrugated tubular box made of an elastomer material, and the longitudinal section of the tube wall is bent in a waveform. There is an air hole 3 on the tube wall, and the speaker unit 1 is fixed on the baffle 5 by bonding, of course, it can also be fixed by screws, etc. One end of the speaker box 2 uses gaskets to compress the edge of the corrugated tubular box and then combines the screws Fixed on the baffle, of course, it can also be fixed by other methods such as bonding, and the other end is closed by bonding the bottom plate 4, so that the speaker unit 1, the speaker box 2 and the bottom plate 4 together form a closed box system, and the back of the speaker unit 1 A cavity is formed between the sound cavity of the speaker box 2 and the bottom plate 4.

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com