Component placement apparatus

A component and equipment technology, applied in the field of component placement equipment, can solve problems such as increased installation cycle time, achieve the effect of reducing moving speed, increasing the number of measurements, and improving installation cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

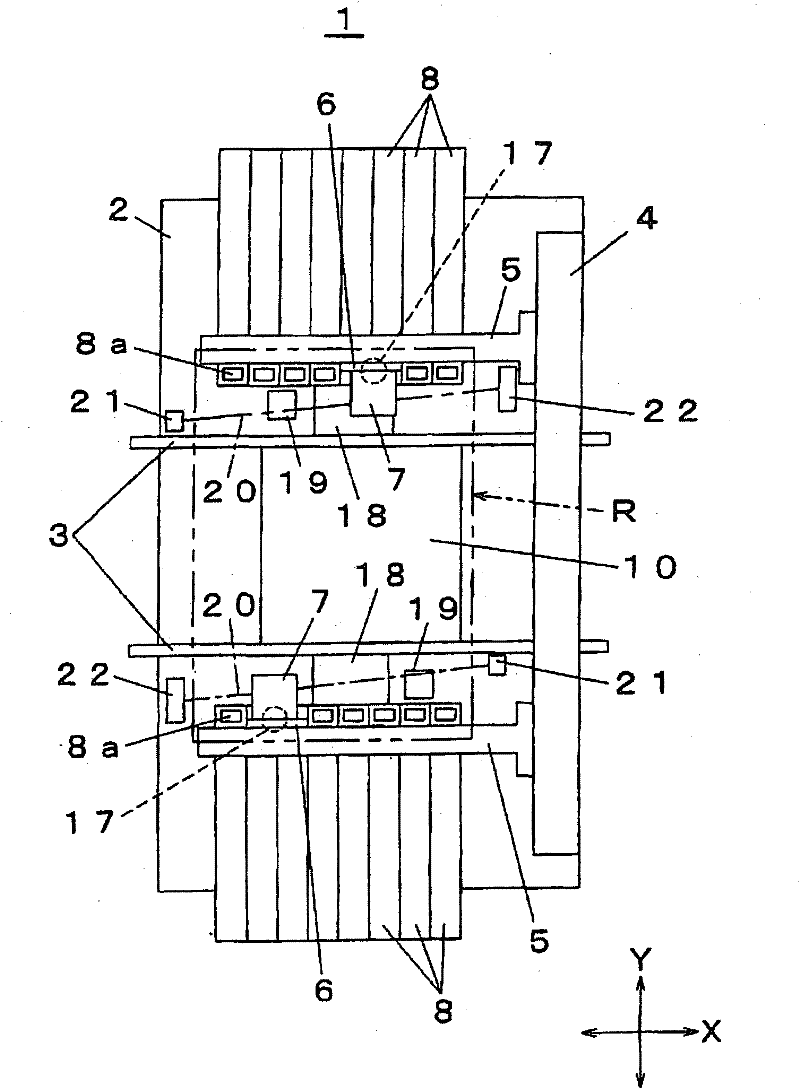

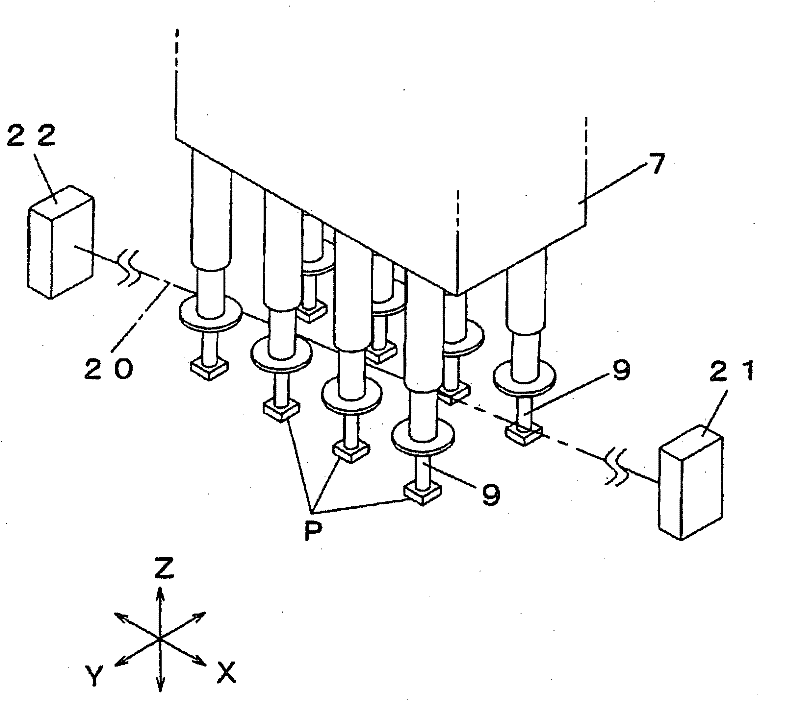

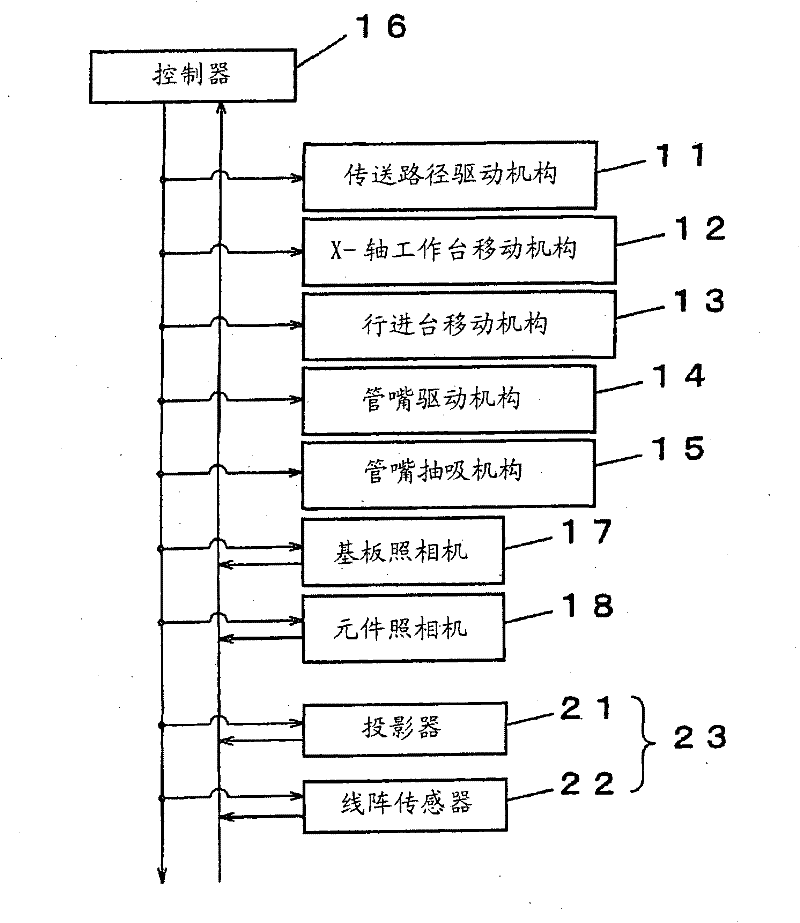

[0031] Embodiments of the present invention will be described with reference to the drawings. figure 1 is a plan view of a component placement apparatus according to an embodiment of the present invention. figure 2 is a perspective view of a mounting head and a line sensor camera according to an embodiment of the present invention. image 3 is a block diagram of a control system of a component placement apparatus according to an embodiment of the present invention. Figure 4 The relationship between the optical axis of the inspection light of the line sensor camera according to the embodiment of the present invention and the traveling track of the mounting head is shown. 5( a ), ( b ), ( c ), ( d ) each show an example of a suction gesture of an element sucked to a suction nozzle according to an embodiment of the present invention. 6( a ), ( b ), ( c ), and ( d ) all show examples of images of components obtained by means of a line array sensor according to an embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com