Automatic-exhaust transfusion device

An automatic exhaust and infusion device technology, applied in the direction of subcutaneous injection equipment, etc., can solve the problems of inconvenient clinical work and cumbersome process, and achieve the effect of reducing work burden and high clinical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

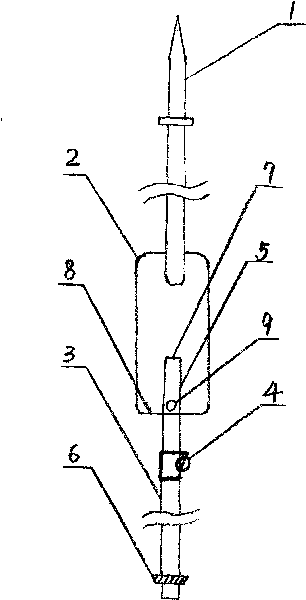

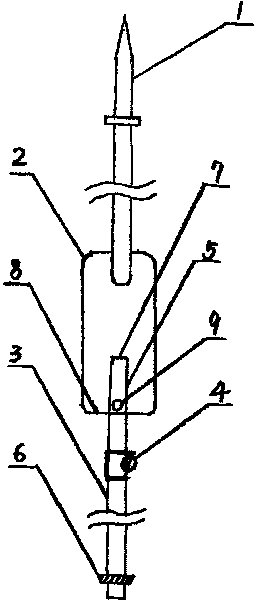

[0008] As shown in the figure, the automatic exhaust infusion set includes a bottle connection plug 1, a Murphy's dropper 2, a hose 3, a governor 4 and a filter 6, and the outlet at the bottom of the Murphy's dropper 2 is The water pipe 5 extends into the lumen of the Murphy's dropper 2, and the mouth 7 of the outlet pipe 5 is higher than the bottom 8 of the Murphy's dropper. A small circular hole 9 is arranged on the water outlet pipe 5 walls.

[0009] When the present invention is in use, during the exhaust and liquid injection process before infusion, after the liquid enters the Murphy's dropper 2, the liquid will first accumulate in the cavity of the Murphy's tube 2, and during the accumulation process, the gas will flow from the outlet pipe 5 is gradually discharged, and when the liquid volume stays at the nozzle 7 of the outlet pipe 5, the liquid flowing into the Murphy's lumen 2 will flow out from the outlet pipe 5, so that there is no need to turn the Murphy's dropper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com