Apparatus for treating a multifilament thread

A multi-fiber and filament technology, applied in textiles and papermaking, etc., can solve problems such as adverse effects, achieve high flexibility, and avoid twisting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

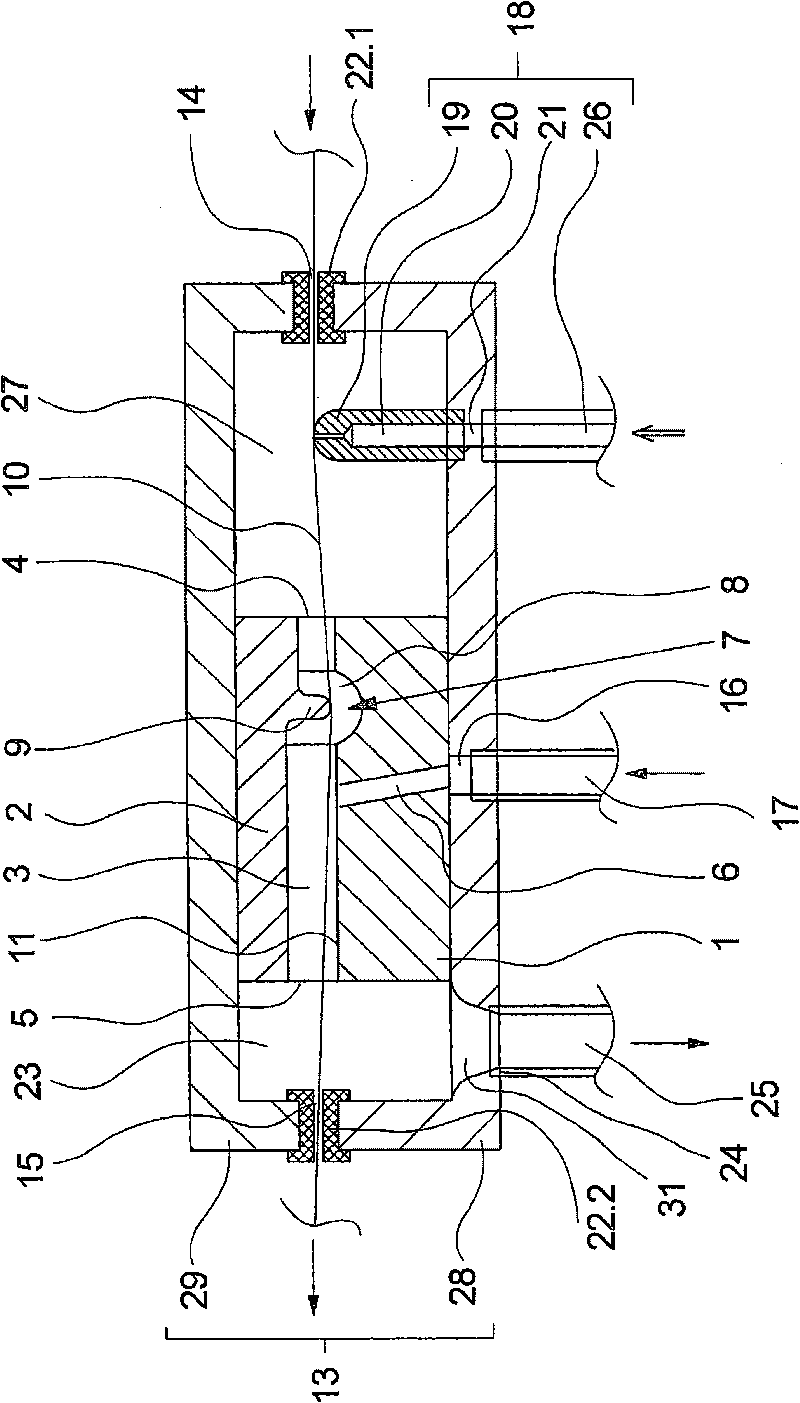

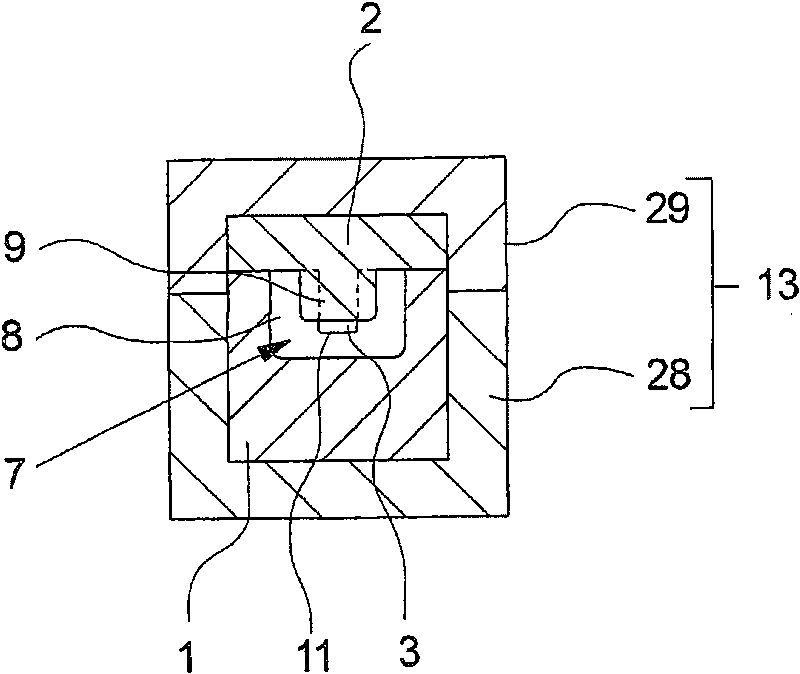

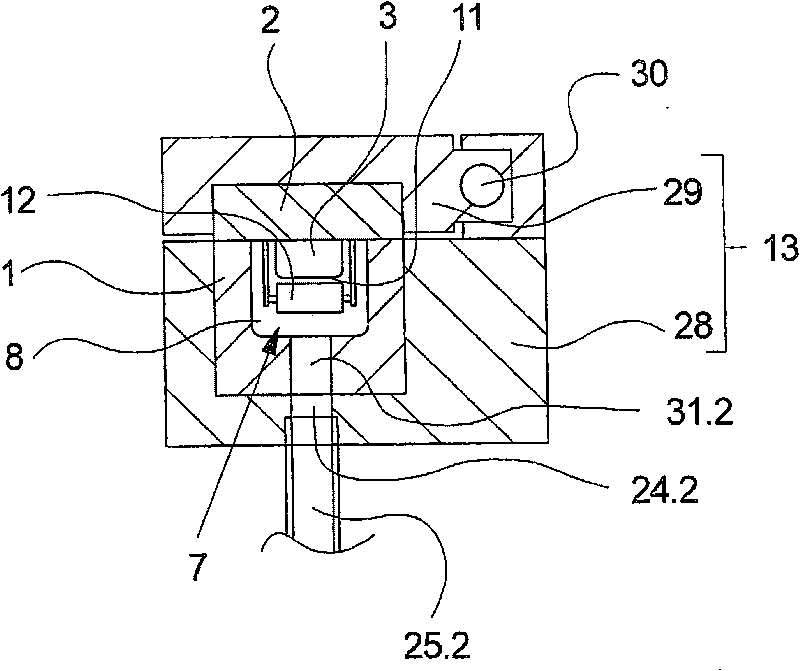

[0034] exist figure 1 and 2 A first embodiment of the inventive device for processing multi-filament filaments is shown in figure 1 The embodiment is shown in longitudinal section and figure 2 The exemplary embodiment is shown in cross section. The following description applies to both figures as long as no figure is specifically indicated.

[0035] exist figure 1In the exemplary embodiment shown, a housing plate 1 and a baffle 2 are arranged in a support housing 13 . On an open longitudinal side, the housing plate 1 has a treatment channel 3 which is groove-shaped on said longitudinal side of the housing plate 1 . The process channel 3 is covered by a baffle placed on the longitudinal side of the housing plate 1 such that the housing plate 1 and the baffle 2 form an inlet 4 and an outlet 5 respectively in the extension of the process channel 3 . A nozzle hole 6 leads into the groove bottom 11 of the treatment channel 3, this nozzle hole 6 passes through the housing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com