Fluid catalyst for preparing acrylonitrile by ammonia oxidation process

A technology of fluidized bed catalyst and ammoxidation method, which is applied in the direction of hydrocarbon ammoxidation preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., which can solve the problem of high reaction by-products and insufficient selectivity Good and other problems, to achieve the effect of high selectivity, high single yield, and inhibition of deep oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

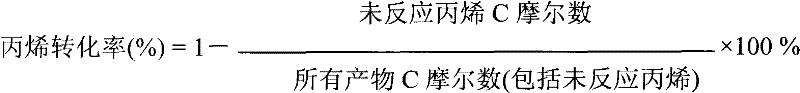

[0046] According to the same catalyst composition of Comparative Example 1, the preparation conditions were used in Table 1. The finished catalyst was inspected according to the above inspection and evaluation conditions, and the initial activity results are shown in Table 2.

[0047] Table 1 Catalyst preparation conditions

[0048] Roasting temperature / ℃

Air / nitrogen / steam ratio / vol%

Micropore / total pore volume / vol%

Comparative example 1

580

100 / 0 / 0

42.3

Example 1

580

90 / 10 / 0

45.6

Example 2

600

90 / 0 / 10

44.8

Example 3

690

70 / 20 / 10

51.2

Example 4

550

50 / 50 / 0

50.5

Example 5

745

40 / 30 / 30

62.9

Example 6

630

40 / 20 / 40

60.7

Example 7

640

30 / 65 / 5

68.4

Example 8

720

20 / 20 / 60

71.0

Example 9

565

10 / 50 / 40

63.3

Example 10

590

60 / 18 / 22

68.1

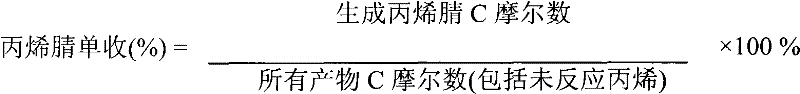

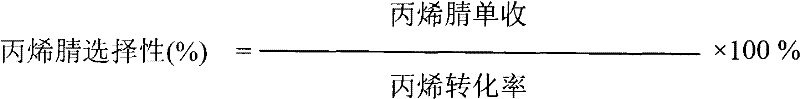

[0049] Table 2 Investigation results of initial activity

[0050] Acrylonitrile single receipt (%)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com