Regeneration method of ammoxidation fluid catalyst

A fluidized bed catalyst, ammonia oxidation technology, applied in catalyst regeneration/reactivation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the decline of acrylonitrile yield and catalyst swelling Broken, unable to evenly impregnate and other problems, to achieve the effect of improving propylene conversion, slowing sublimation loss, and easy molecular diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

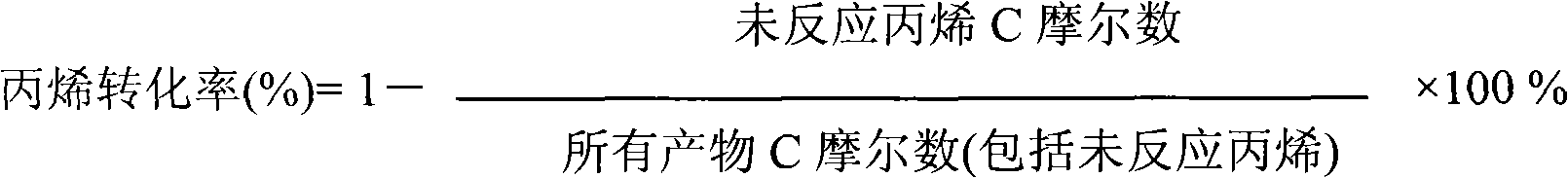

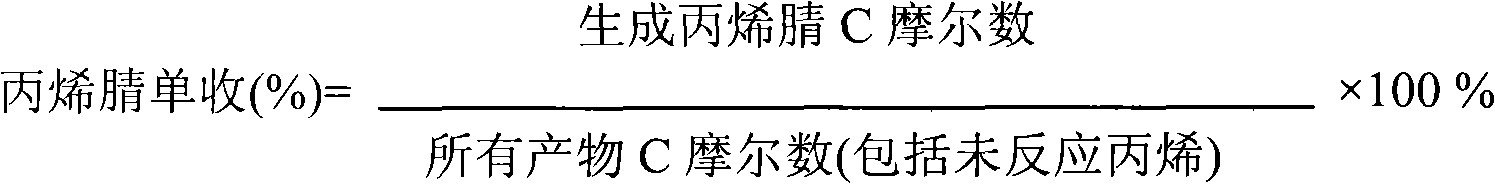

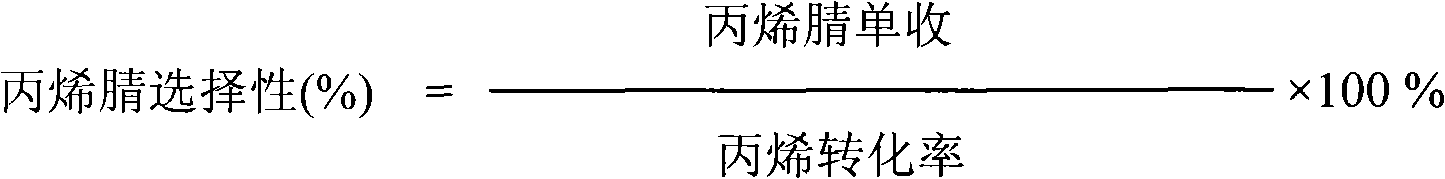

Embodiment 1

[0030] According to fresh bulk acrylonitrile fluidized bed catalyst (Mo 12 Bi 2.0 Fe 2.5 Ni 5.5 Mg 1.8 La 0.8 K 0.05 Cs 0.05 Na 0.05 +50% SiO2 2 ) composition requirements, the equilibrium catalyst is supplemented with molybdenum components of corresponding content, and the catalyst is roasted and regenerated according to the process conditions in Tables 1-3. Tables 1 to 3 are the regeneration results of the catalyst under different regeneration conditions. The effect is obvious, especially in the regeneration under the mixed atmosphere, the single acrylonitrile yield of the catalyst can reach more than 82%, which is more than 4 to 5 percentage points higher than that of the equilibrium catalyst before regeneration.

[0031] Table 1 Regeneration effect of different molybdenum sources

[0032]

[0033] * Note 1: AN acrylonitrile ACN acetonitrile ACHO acrolein HCN hydrocyanic acid

[0034] * Note 2: The firing conditions are air atmosphere, 580°C, 1 hour

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com