Honeycomb intensive rotary garage

A honeycomb-like, intensive technology, applied in the field of garages, can solve the problems of fixing a single storage body, lack of safety, and prone to collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

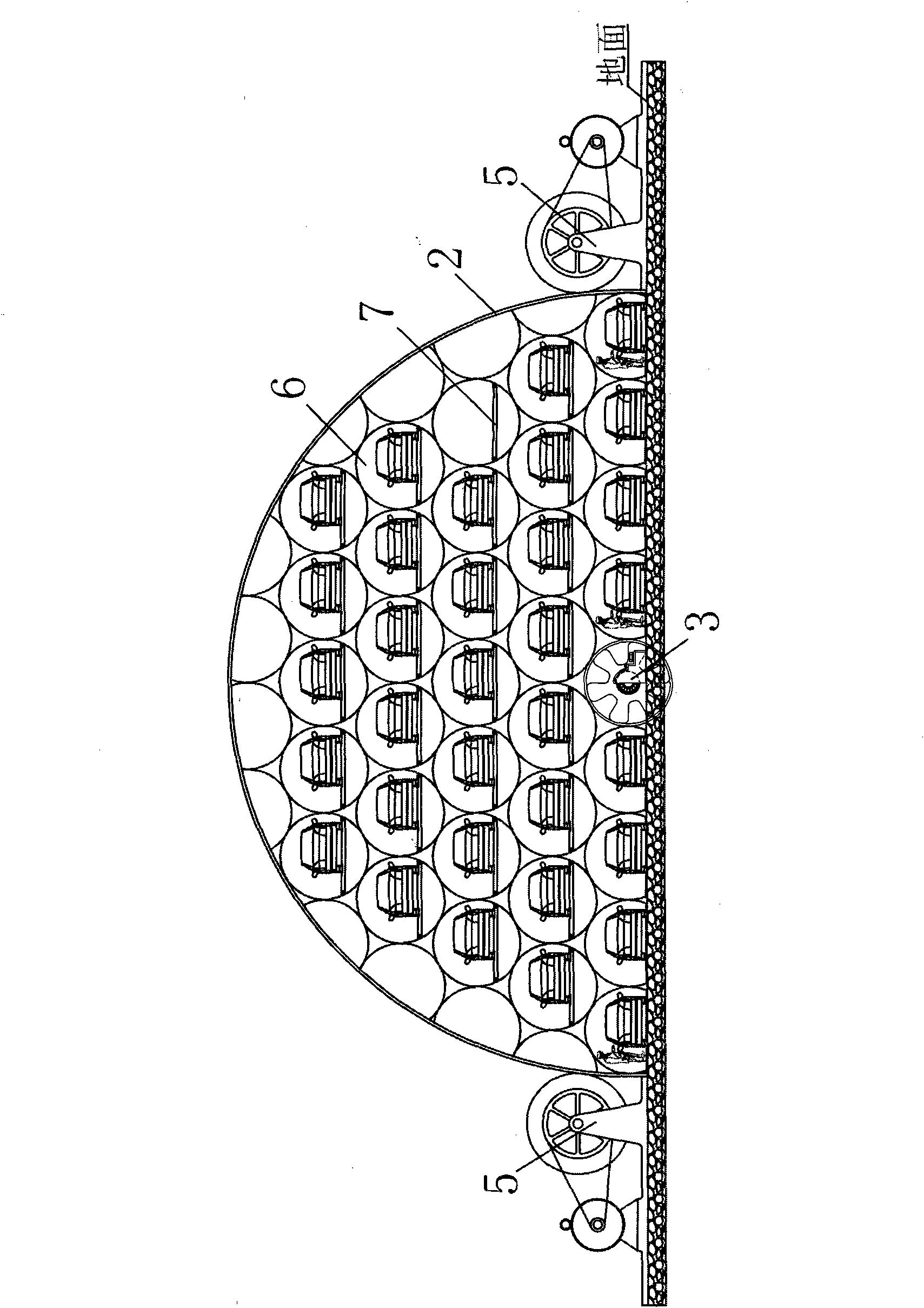

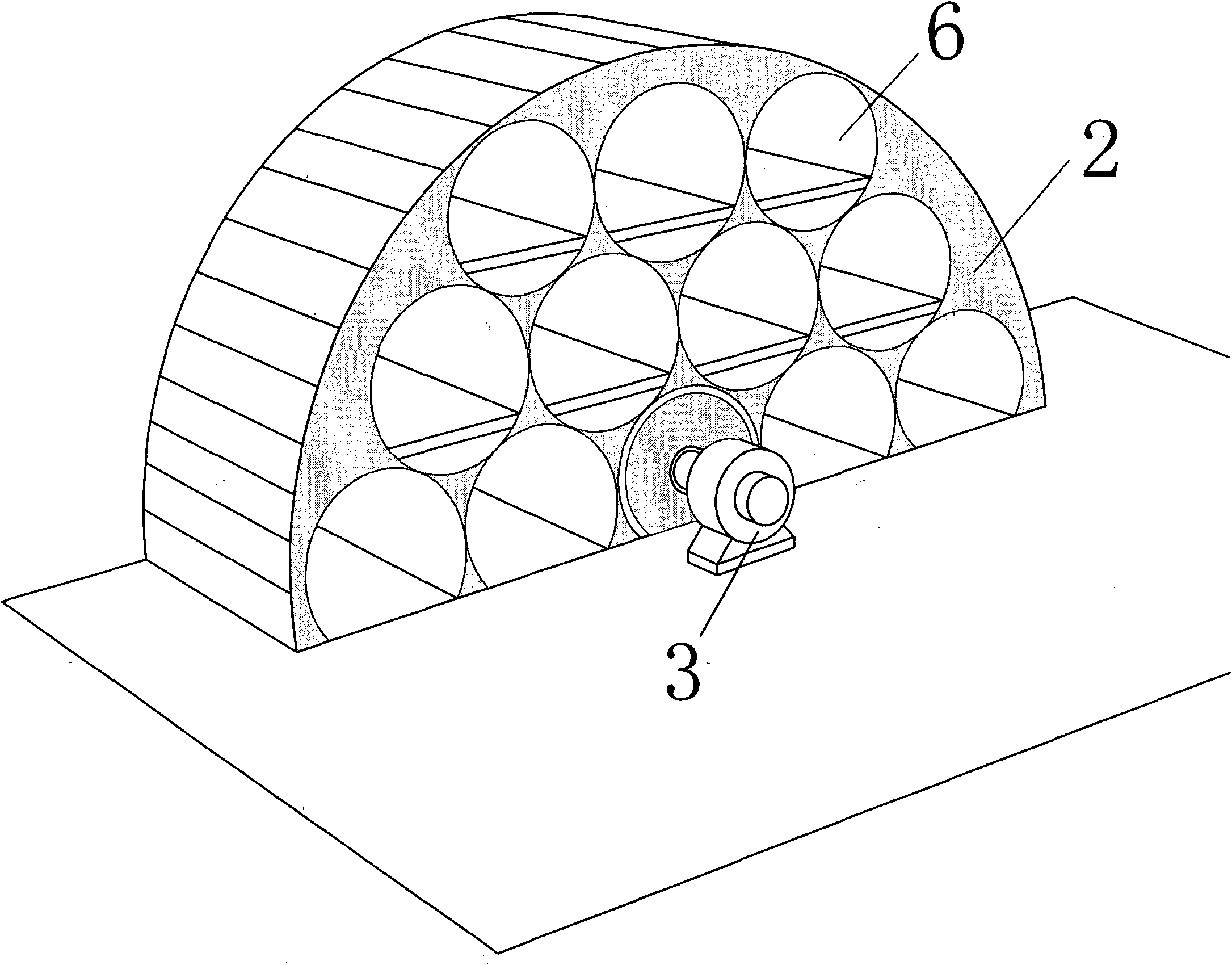

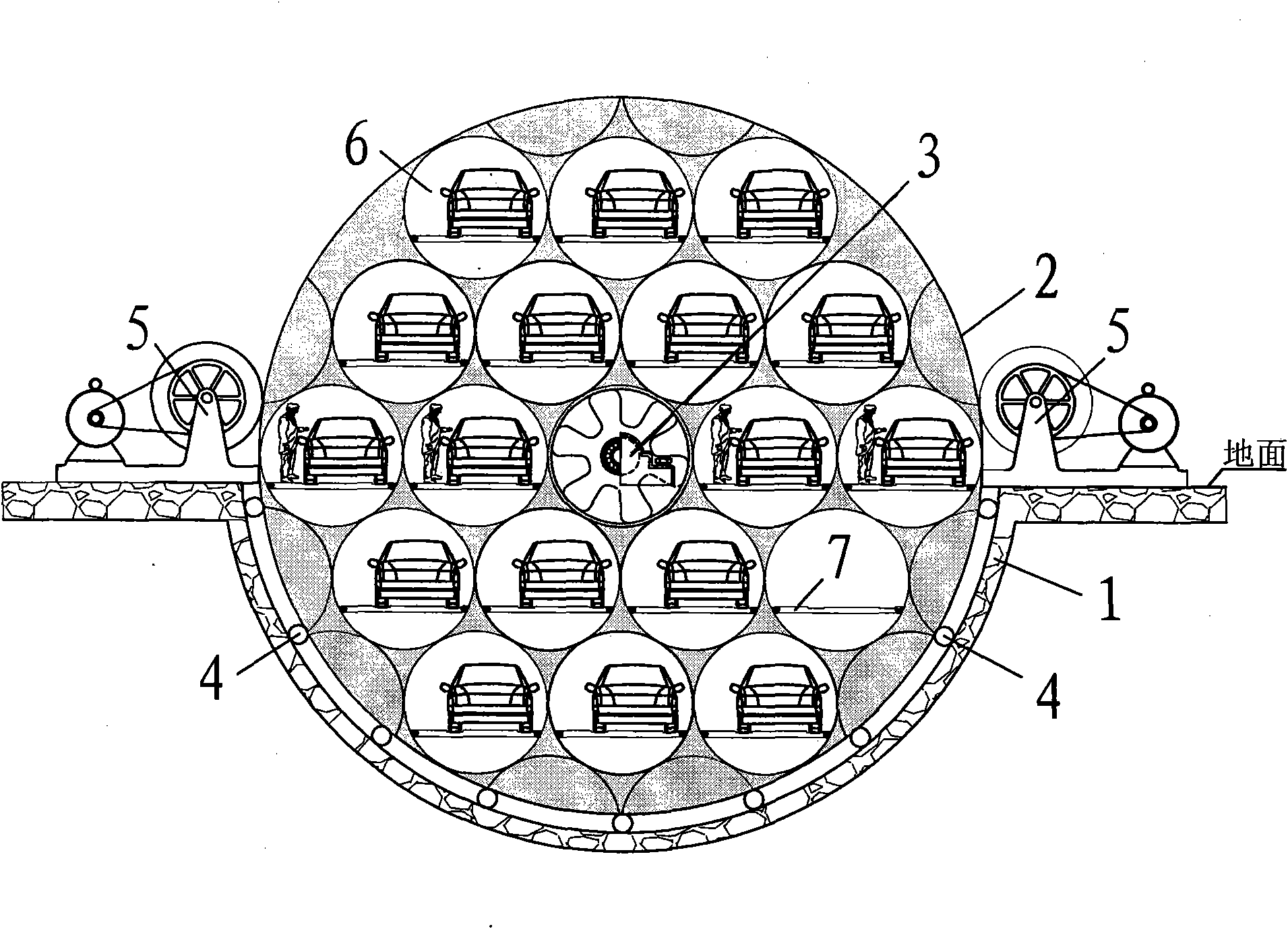

[0016] figure 1 , figure 2 , image 3 The basic embodiment of the present invention is shown, the surface of the hard arc bottom pit (1) has several bottom pit roller assemblies (4), and one-half part of the body (2) is put into the hard arc In the bottom pit (1), the main body (2) is jointly supported by the main shaft assembly (3) and the bottom pit roller assembly (4). There are several tubular parking cars (6) in the body of the body (2) according to the honeycomb Arranged and connected in combination, the ground portion of the hard arc-shaped bottom pit (1) has more than one transmission device (5) for clockwise or counterclockwise driving against the body (2).

[0017] Figure 4 , Figure 5 The embodiment of the tubular parking car (6) of the present invention is shown, a parking platform (7) is arranged in the tubular parking car,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com