Air guide rail

一种导轨、空气的技术,应用在气垫轴承、安装、光学等方向,能够解决成本高、增大导套内侧摩擦力等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The air guide rail 100 of the present invention will be further described in detail below with reference to the drawings and specific embodiments.

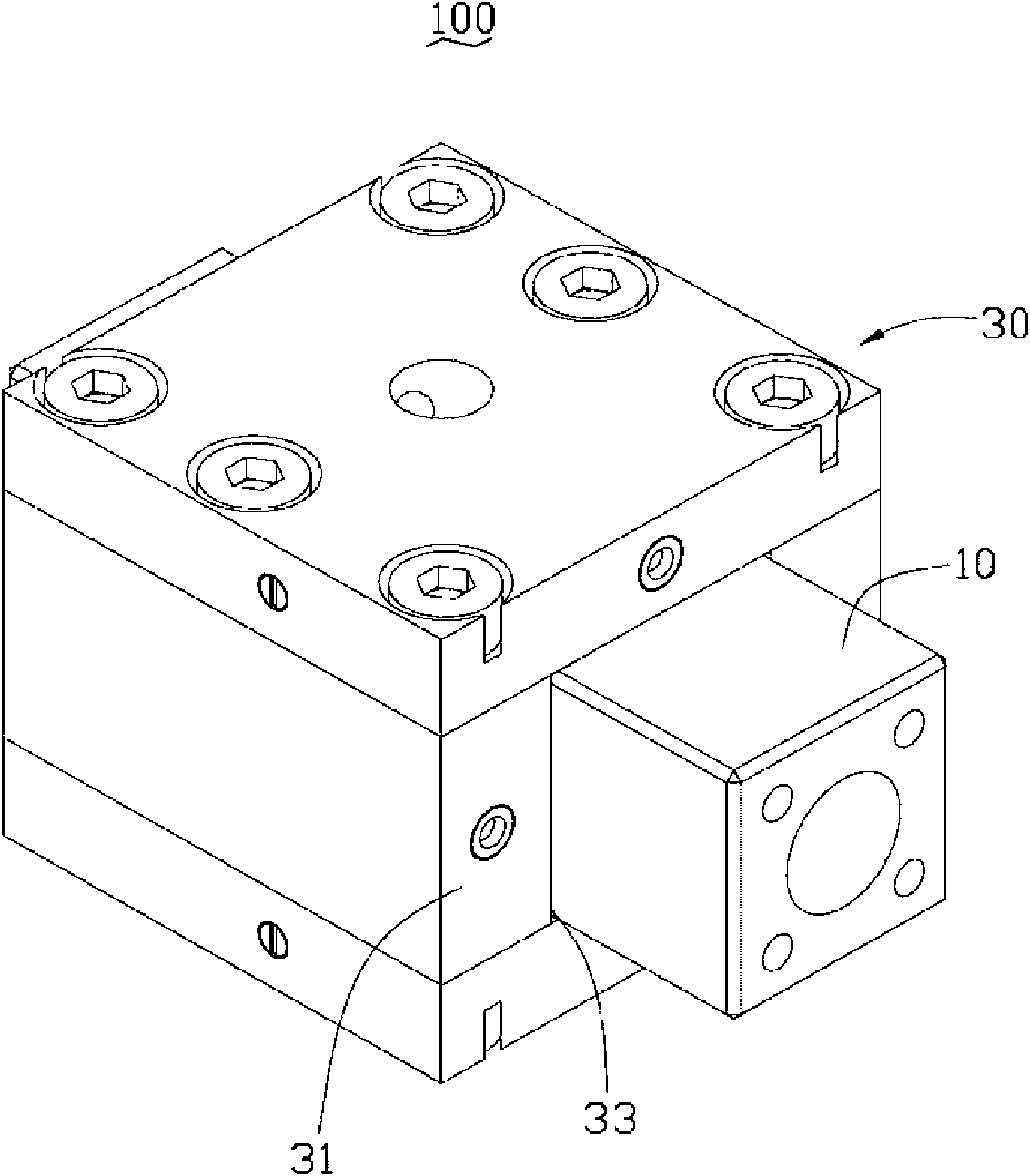

[0014] see figure 1 , the air guide rail 100 includes a guide core 10 and a guide sleeve 30 sleeved on the guide core 10 .

[0015] In this embodiment, the guide core 10 is a hollow structure with a square cross section. Therefore, the guide core 10 has the advantages of light weight and convenient manufacture.

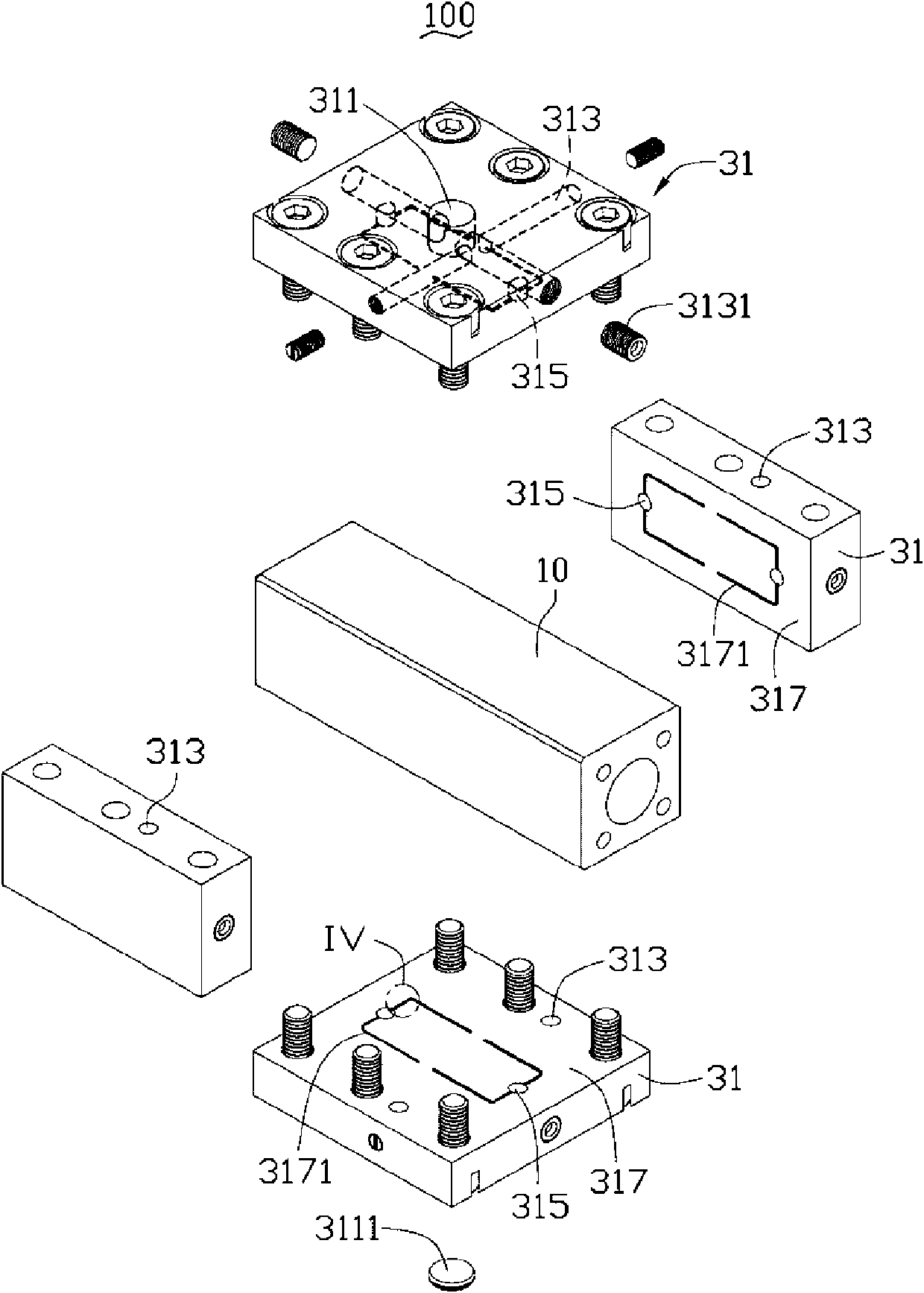

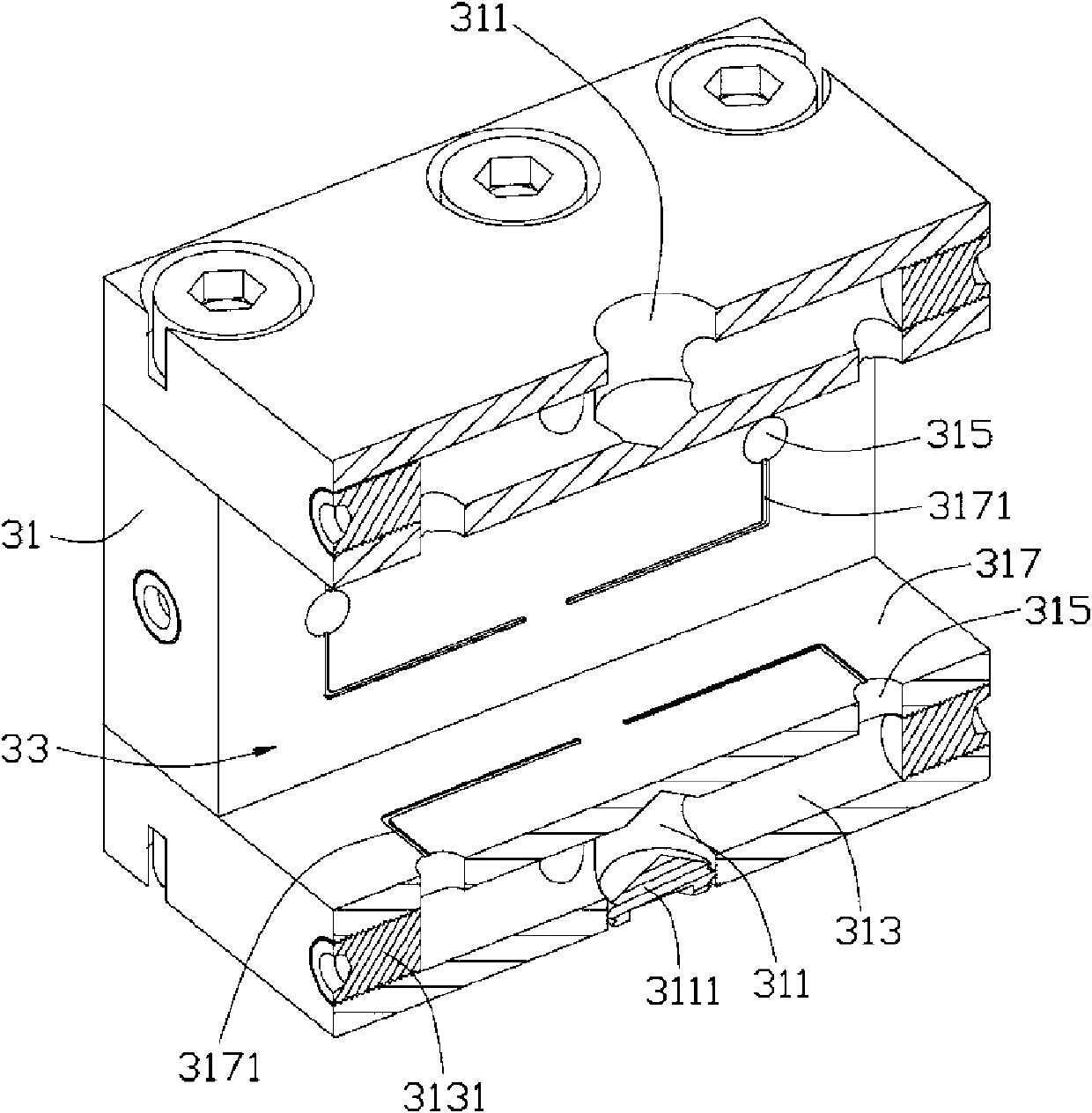

[0016] see again figure 2 and image 3 Correspondingly, the guide sleeve 30 is connected to a rectangular parallelepiped by four members 31 with a rectangular cross-section, and the four members 31 are connected to form a square central hole 33, and the guide core 10 is slidably accommodated in each member 31 to form a In the center hole 33 of the The components 31 can be connected by means of screw connection, riveting, welding or gluing. In this embodiment, the components 31 are connected by screws.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com