Polymer dispersed liquid crystal layer and preparation method, polymer dispersed liquid crystal film and preparation method

A technology for dispersing liquid crystal and polymer, applied in the fields of polymer dispersed liquid crystal layer and preparation, polymer dispersed liquid crystal film and preparation, can solve the problems of reduced open-state transmittance, difficult to obtain, increased driving voltage, etc. The effect of reducing the state transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

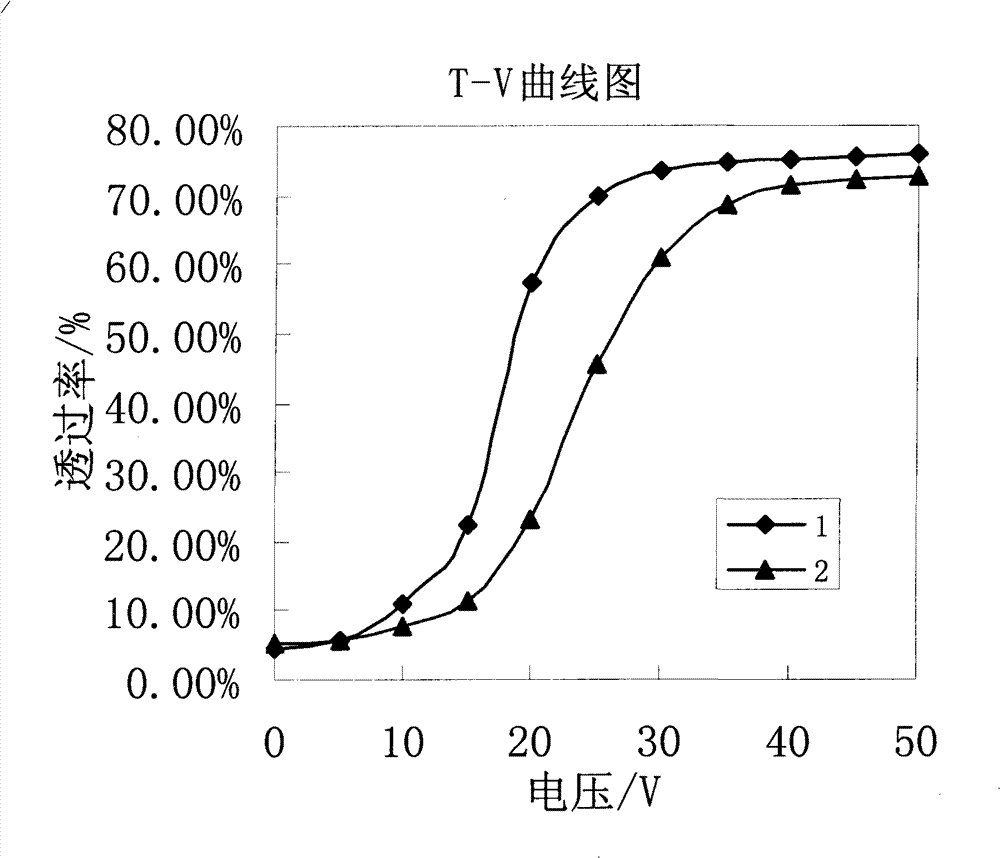

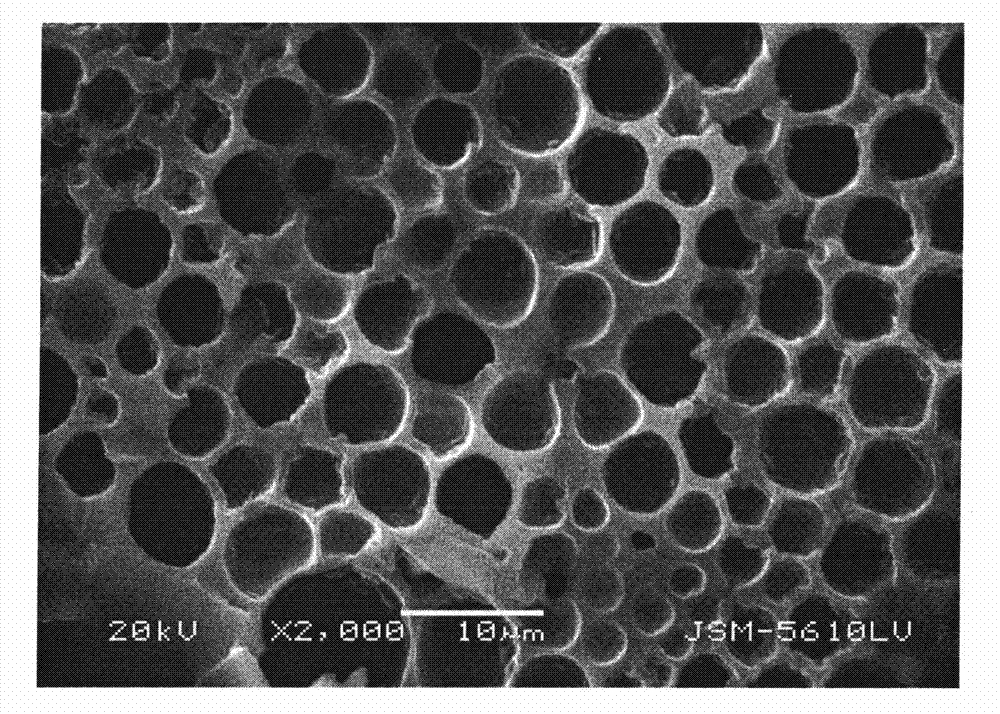

[0048] Weigh 30wt% polymer monomer as NOA65 and 70wt% liquid crystal E7, a total of 100 grams, in the container, add 1.5 grams of glass beads with an average particle diameter of 15um as a spacer, weigh 1.2 grams of 1-phenylamino- 4-(Methylamino)anthraquinone, mixed evenly to obtain a mixture, the liquid crystal E7 has a clearing point of 80 degrees, heated the mixture to about 85°C, stirred evenly, and spread it between two pieces of ITO glass at 365nm Ultraviolet light with a wavelength of 5 mw / cm2 light intensity was irradiated for 4 minutes at a room temperature of 25° C. to obtain a polymer dispersed liquid crystal film A1.

Embodiment 2

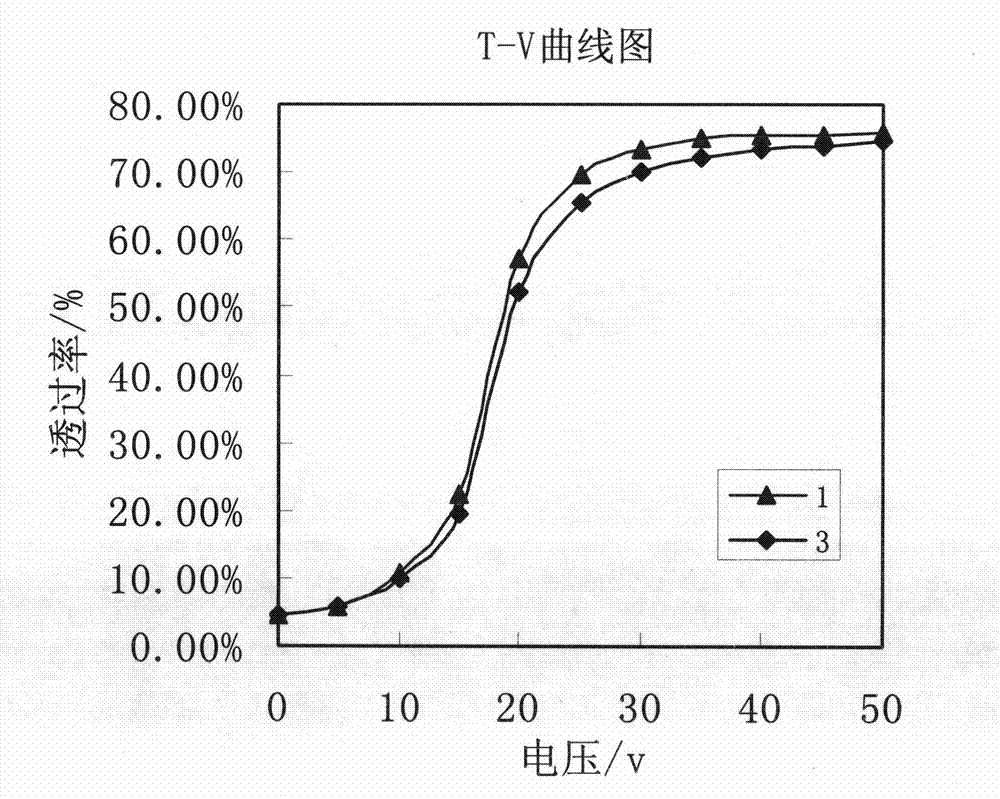

[0050] Same as Example 1, the difference lies in 40wt% polymer monomer and 60wt% liquid crystal, the weight percentage of polymer monomer and liquid crystal is 40:60, and the polymer dispersed liquid crystal film A2 is obtained.

Embodiment 3

[0052] Same as Example 1, the difference lies in 50wt% polymer monomer and 50wt% liquid crystal, the weight percentage of polymer monomer and liquid crystal is 50:50, and polymer dispersed liquid crystal film A3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com