Positive lithograph plate photosensitive composition with high resolution and high sensitivity

A high-sensitivity, high-resolution technology, applied to photosensitive materials used in optomechanical equipment, photoplate-making processes on patterned surfaces, optics, etc. Guarantee, increase the complexity of the formula, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

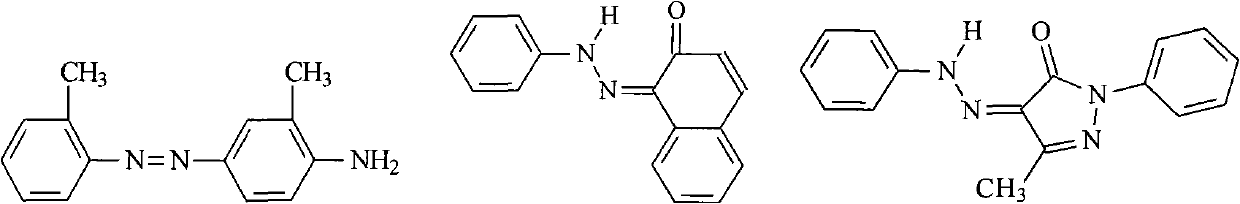

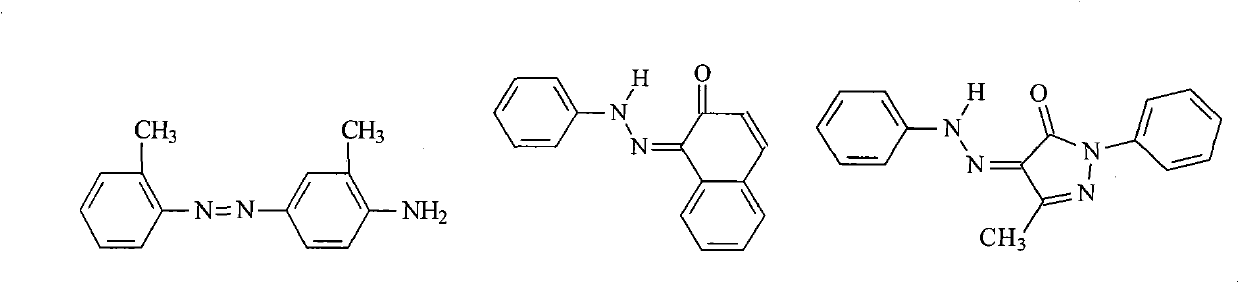

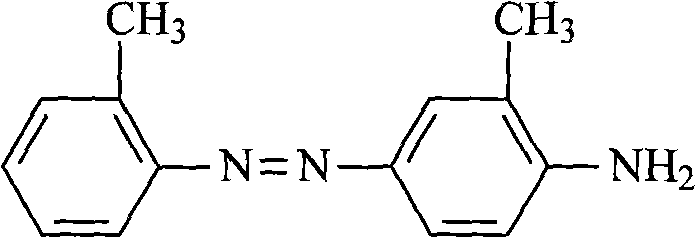

Image

Examples

Embodiment 1

[0035] The photosensitive composition of the high-resolution and high-sensitivity positive-working lithographic plate is as follows:

[0036] (a) Film-forming resin: BTB-24 (Weihai Tiancheng Chemical Factory) 6.40g

[0037](b) Add resin: SP-1077 (SI Group) 0.20g

[0038] (c) Photoactive resist: PAC214 / PAC215 (The Second Film Factory of Lucky Group) 1.2 / 1.2g

[0039] (d) Source of photoacid generation: TB (the second film factory of Lucky Group) 0.15g

[0040] (e) UV absorbing dye: Dye 1 (Clariant) 0.05g

[0041] (f) background coloring dye: OB-603 (Beijing Chemical Factory) 0.3g

[0042] (g) Solubilizer: 0.5 g of citric acid.

[0043] The above-mentioned photosensitive composition was dissolved in 90 grams of ethylene glycol monoethyl ether solvent to prepare photosensitive solution 1 with a solid content of 10%.

Embodiment 2

[0045] The photosensitive composition of the high-resolution and high-sensitivity positive-working lithographic plate is as follows:

[0046] (a) film-forming resin: phenol-m-cresol-formaldehyde resin 25g

[0047] (b) Add resin: SP-1077 (SI Group) 10g

[0048] (c) Photoactive resist: PAC214 / PAC215 (The Second Film Factory of Lucky Group) 6.67 / 33.33g

[0049] (d) Source of photoacid generation: 1-phenyl-3,5 bistrichloromethyl triazine 5g

[0050] (i) UV absorbing dye: Dye II (Clariant) 5g

[0051] (f) Background coloring dye: basic brilliant blue 5g

[0052] (g) Solubilizer: maleic acid 10g.

[0053] The above photosensitive composition was dissolved in 233 grams of butanol solvent to prepare photosensitive solution 2 with a solid content of 30%.

Embodiment 3

[0055] The photosensitive composition of the high-resolution and high-sensitivity positive-working lithographic plate is as follows:

[0056] (a) film-forming resin: o-cresol-formaldehyde resin 80g

[0057] (b) Add resin: SP-1077 (SI Group) 2g

[0058] (c) Photoactive resist: PAC214 / PAC215 (The Second Film Factory of Lucky Group) 3.33 / 6.67g

[0059] (d) Source of photoacid generation: 1-methoxyphenyl-3,5 bistrichloromethyl triazine 0.1g

[0060] (j) Ultraviolet absorbing dye: Dye III (Clariant) 0.01g

[0061] (f) Background coloring dye: Victoria Pure Blue 0.5g

[0062] (g) Solubilizer: 7.39g of phthalic acid.

[0063] The above photosensitive composition was dissolved in 400 grams of methyl ethyl ketone solvent to prepare photosensitive solution 3 with a solid content of 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com