Detailed design for working drawing of bent-torsional member

A technology for detailed design of bending and torsion components, applied in the field of detailed design of construction drawings, can solve problems such as complex detailed design, achieve the effect of guiding workshop production and avoiding mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: refer to Figure 1-9 . The detailed design method of the construction drawing of the bending and torsion member includes the following steps:

[0023] a. In the computer, according to the coordinates of the outer contour given by the construction drawing of the bending and torsion member, they are connected with spline curves to form a space line network;

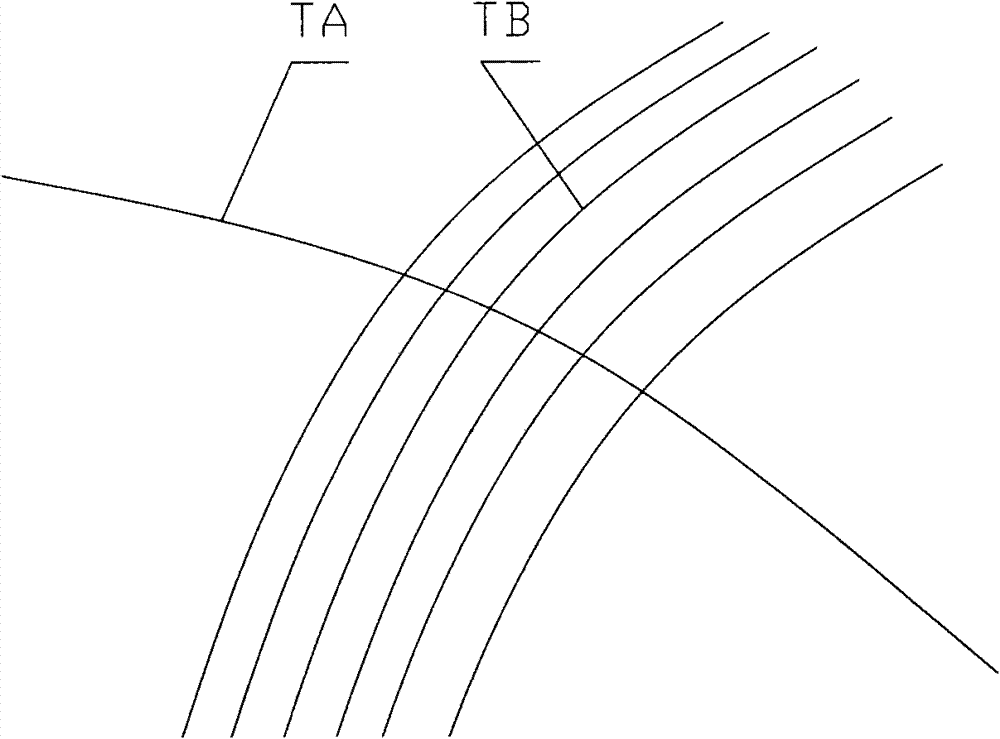

[0024] b. Select two intersecting spline curves TA and TB with larger curvature in the space line network;

[0025] c. According to the offset x given in the construction drawing of the bending and torsion member, the two spline curves are respectively offset into four curves, and the connecting line between the four curves is formed into a rectangle;

[0026] d. For the four curves offset by two intersecting spline curves, every two adjacent curves form a surface. Select the surface generated by the four curves offset by one of the spline curves as a whole, and use the other curve The surface genera...

Embodiment 2

[0030] Embodiment 2: refer to figure 1 and 2 . The two intersecting spline curves described in step b are two spline curves with relatively large curvature in the space line network.

Embodiment 3

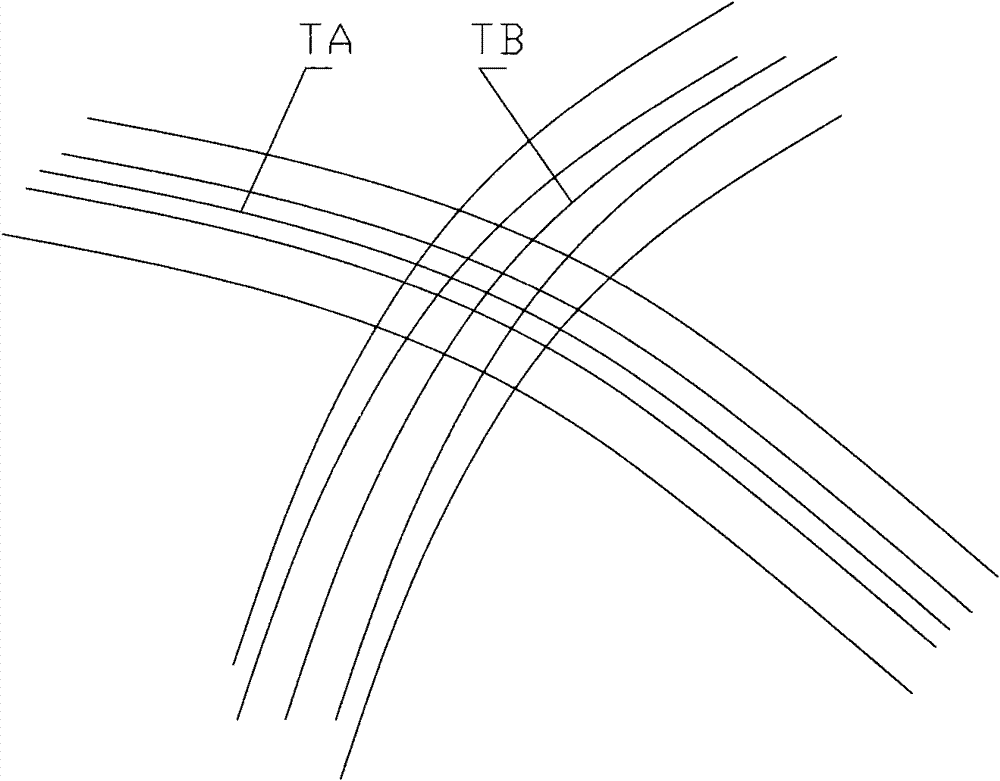

[0031] Embodiment 3: refer to image 3 , 4 , 5, 6, 7 and 8. In step d, the spline curve TA offsets four curves according to the given offset x of the construction drawing of the bending and torsion member, which are curves TA1, TA2, TA3 and TA4, and the adjacent two curves TA1 and TA2 form a surface V1, and the curve TA2 and TA3 form a surface V2, curves TA3 and TA4 form a surface V3, and curves TA4 and TA1 form a surface V4;

[0032] Select the surface composed of the four offset curves from TA as a whole, then the spline curve TB is cut into two parts, namely TB1, TB2, and TB3, according to the given offset x of the construction drawing of the bending and torsion member. . Curves TB6 and TB7 form surface V5, curves TB6 and TB7 form surface V6, curves TB7 and TB8 form surface V7, and curves TB8 and TB5 form surface V8; each surface is stretched by y distance to form a plate, where y is the construction drawing of the bending and torsion member A given stretch distance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com