Limited volume high performance flush valve assembly

A technology of flushing valves and components, applied in flushing equipment with water tanks, water supply devices, buildings, etc., to achieve high fluid flow rate and more available energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Detailed description of the preferred embodiment

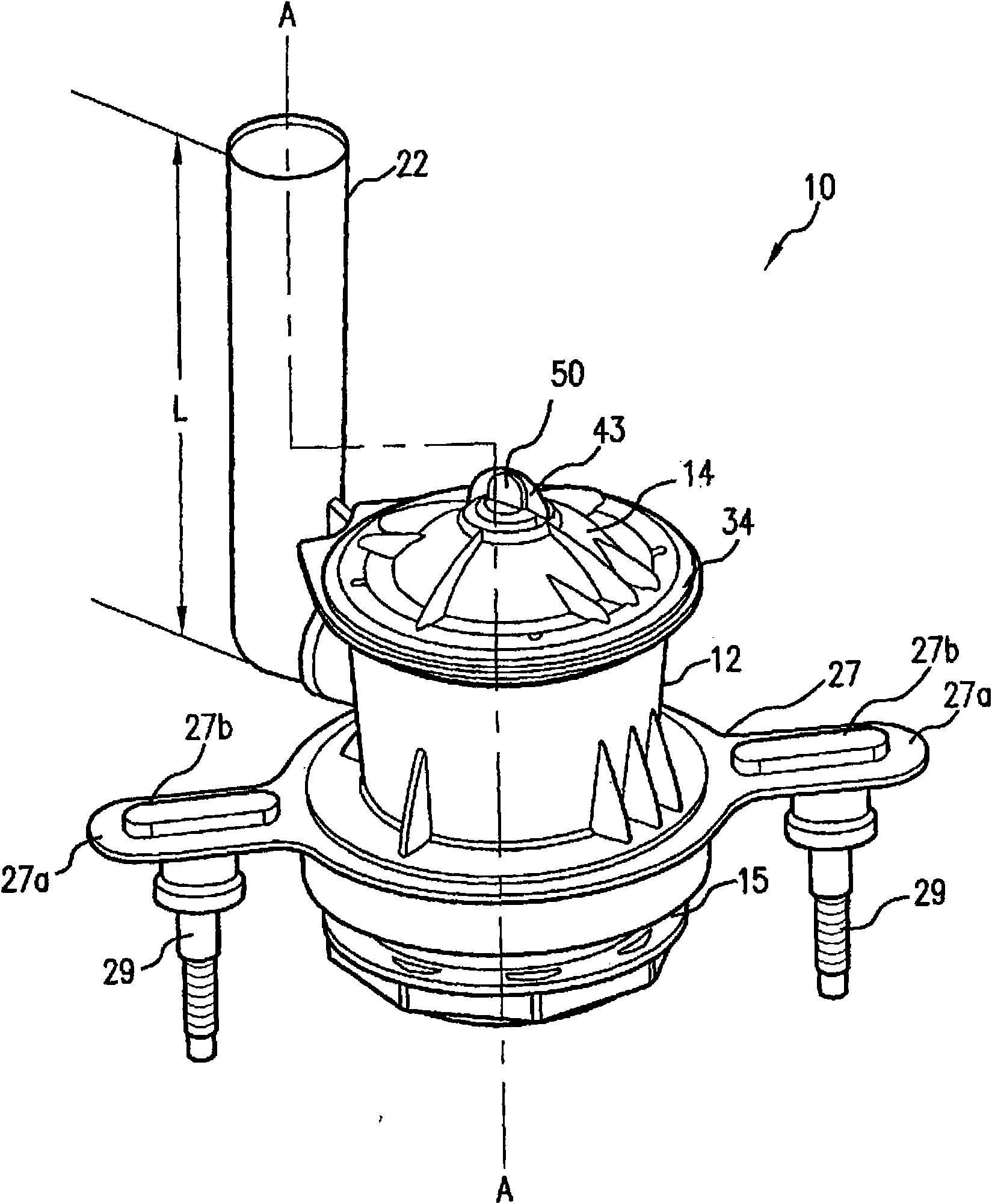

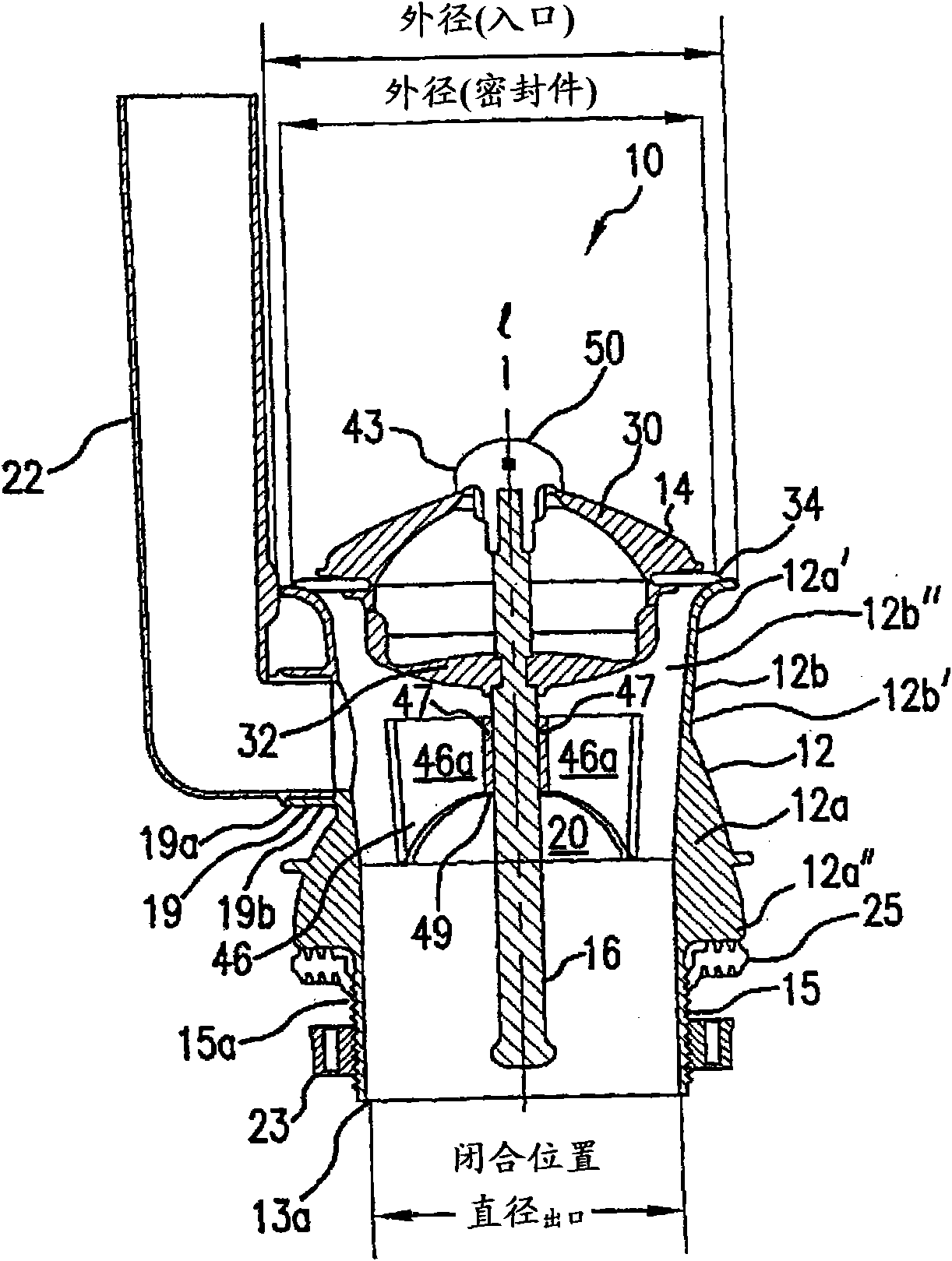

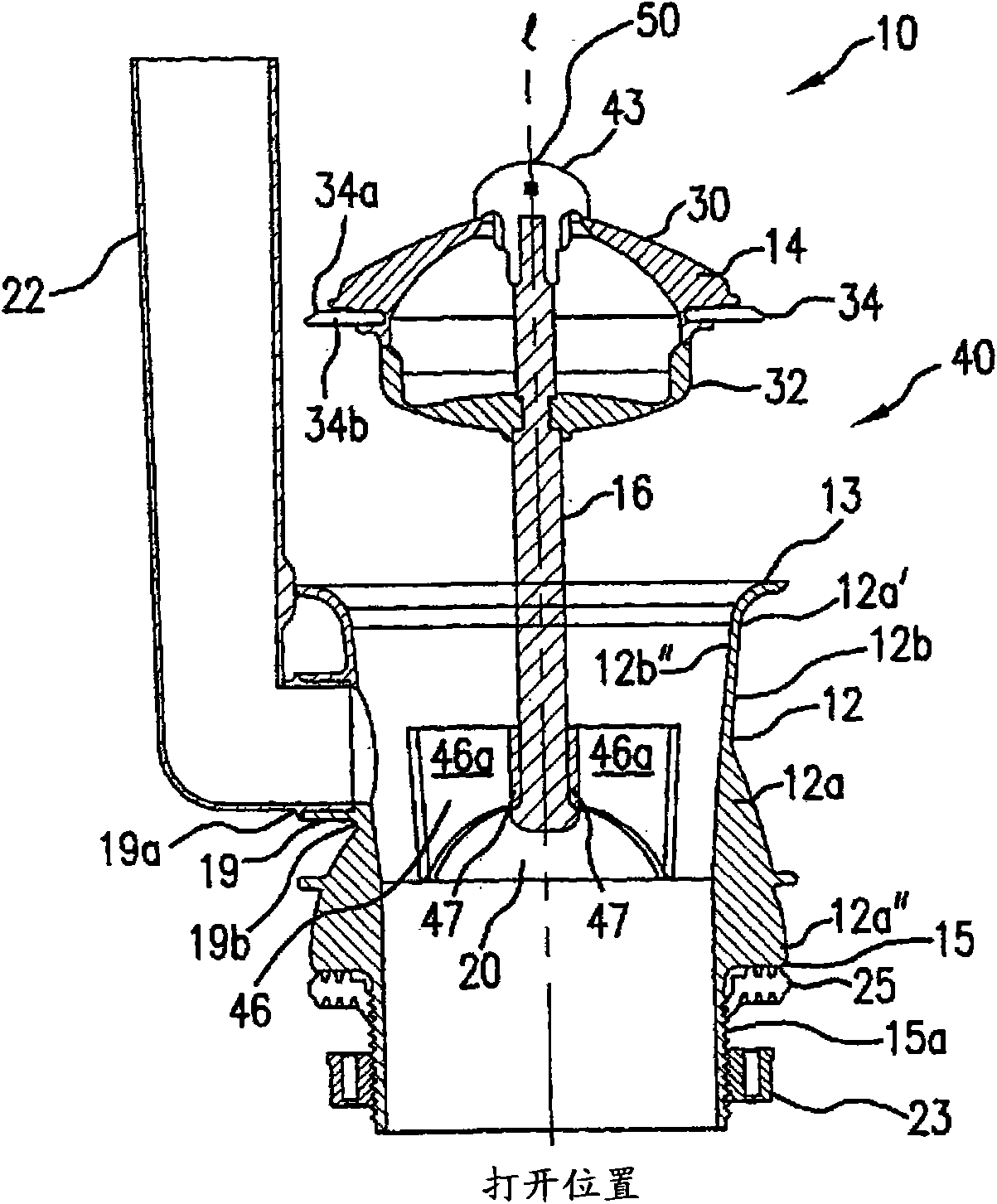

[0025] As shown, wherein like numerals indicate like elements, the flush valve assembly 10 of the present invention is disposed in a tank 200 of a toilet assembly (in Figure 4 shown in ), wherein the water tank stores water for delivery to a bowl in fluid communication with the water tank. Flush valve assembly 10 is operable with a conventional priming valve 205, which may be selected from any known priming valve consistent with the successful practice of the present invention. Flush valve assembly 10 is operable upon actuation of an actuating device, such as trip lever 210, as further described below.

[0026] Valve assembly 10 includes a body subassembly 12 in operative communication with a movable poppet sealing subassembly 14 via a guide rod 16 having a predetermined length. The main body subassembly 12 includes a valve body 12a having a proximal extension 12a' and a distal extension 12a" and a coextensive wall 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com