Steam marinating pot provided with drum-type food cage

A food material cage and drum type technology, applied in the direction of utensils with enlarged heating surfaces, food science, etc., can solve the problems of stewed products that are difficult to overcome, such as the quality of stewed products, inconsistent taste between raw and cooked, and high labor intensity, etc., to achieve reduction The probability of cross-contamination, the effect of reducing energy consumption and reducing the number of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

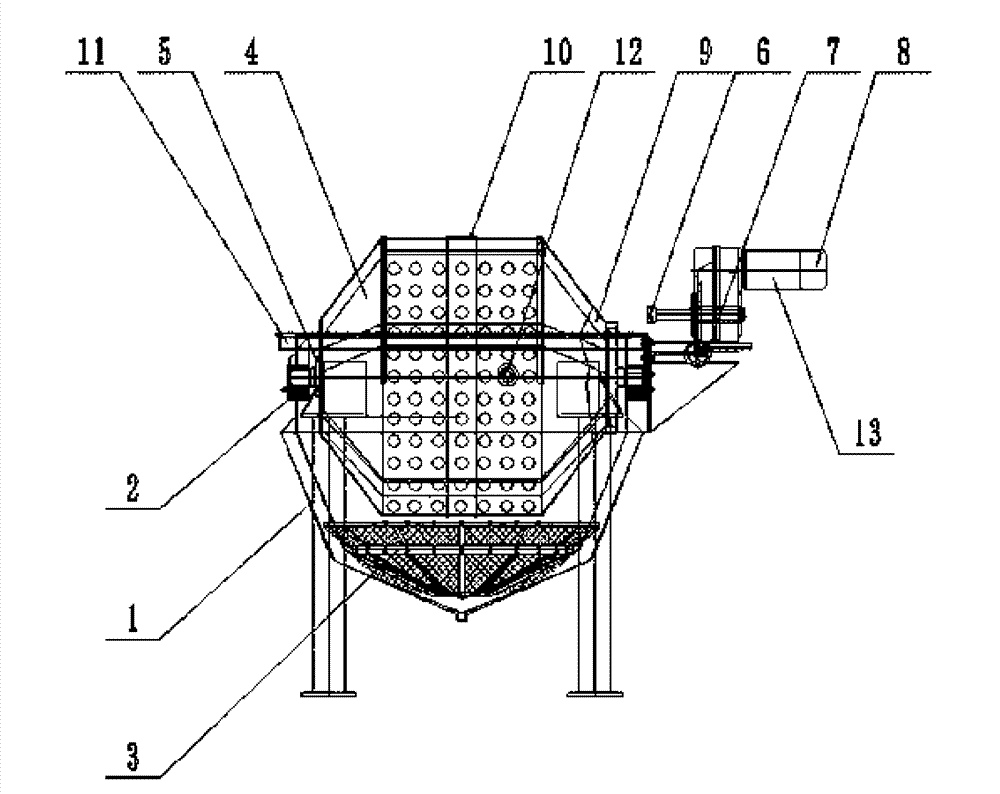

[0014] The present invention will be further described below in conjunction with the accompanying drawings and examples of implementation.

[0015] With reference to the accompanying drawings, this example includes a steam-heated sandwich pot body 1, a movable stewed medicine cage 3 is placed at the bottom of the stewed pot, and a drum-type food material cage 2 is arranged above the stewed medicine cage 3, and the center of the drum-type food material cage 4 The rotating shaft 5 is placed on the open sliding bearing housing 2 on both sides of the interlayer pot body 1, and is connected with the driving frequency conversion speed regulating motor 8 through the transmission gear 6 and the clutch 7; Rib 9, drum-type food material cage 4 outer wall is provided with the stainless steel door 10 with fast opening lock; Pot mouth is equipped with stainless steel edge 11;

[0016] The brine medicine cage 3 and the drum type food material cage 4 are all made of stainless steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com