Retractable hot runner system

A hot runner and telescopic technology, applied in the field of hot runner, can solve the problems of reducing the temperature of the hot runner, heat loss of the hot runner system, and high matching accuracy between the hot runner system and the mold, and achieve the effect of reducing processing requirements and reducing heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

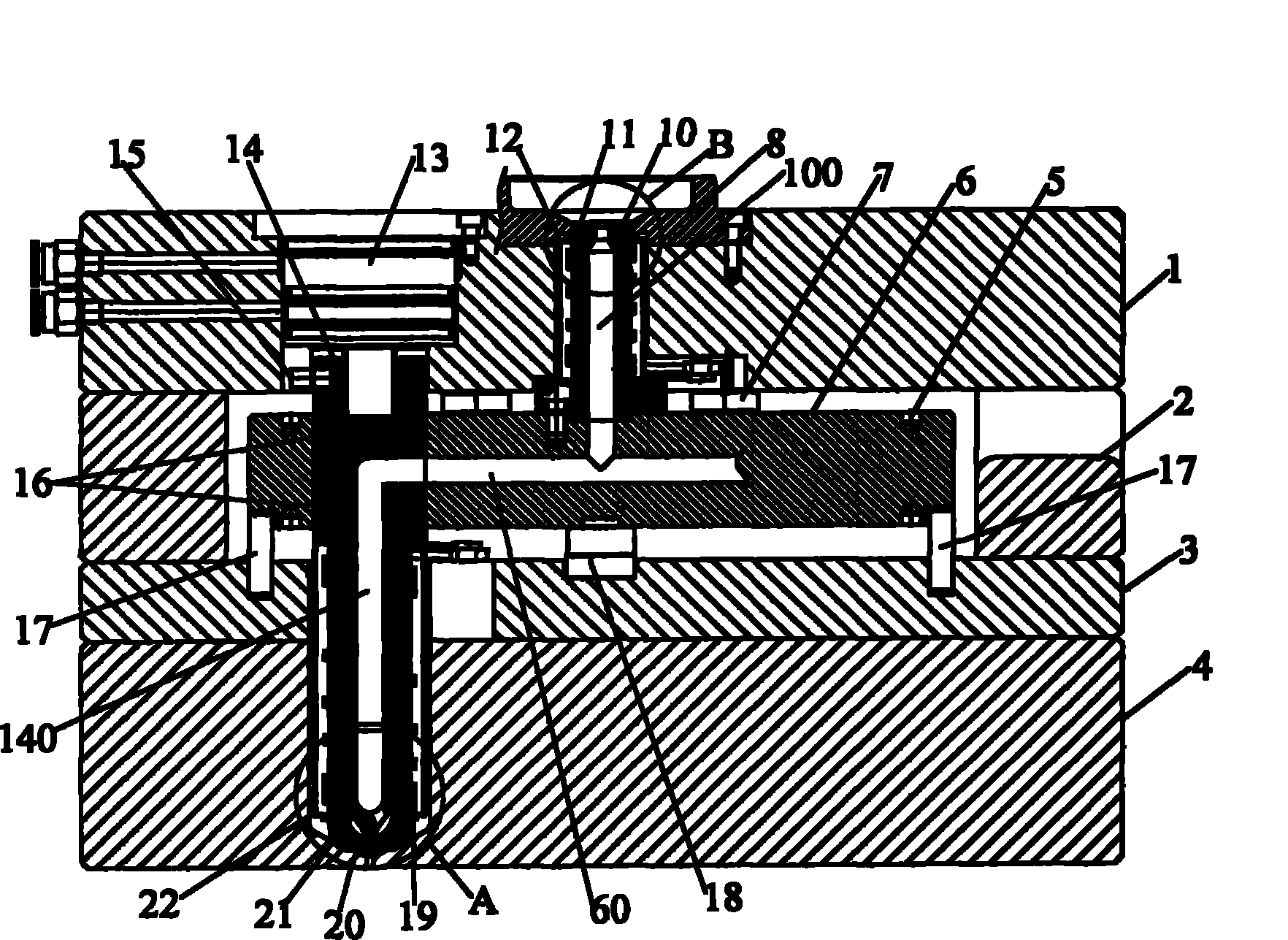

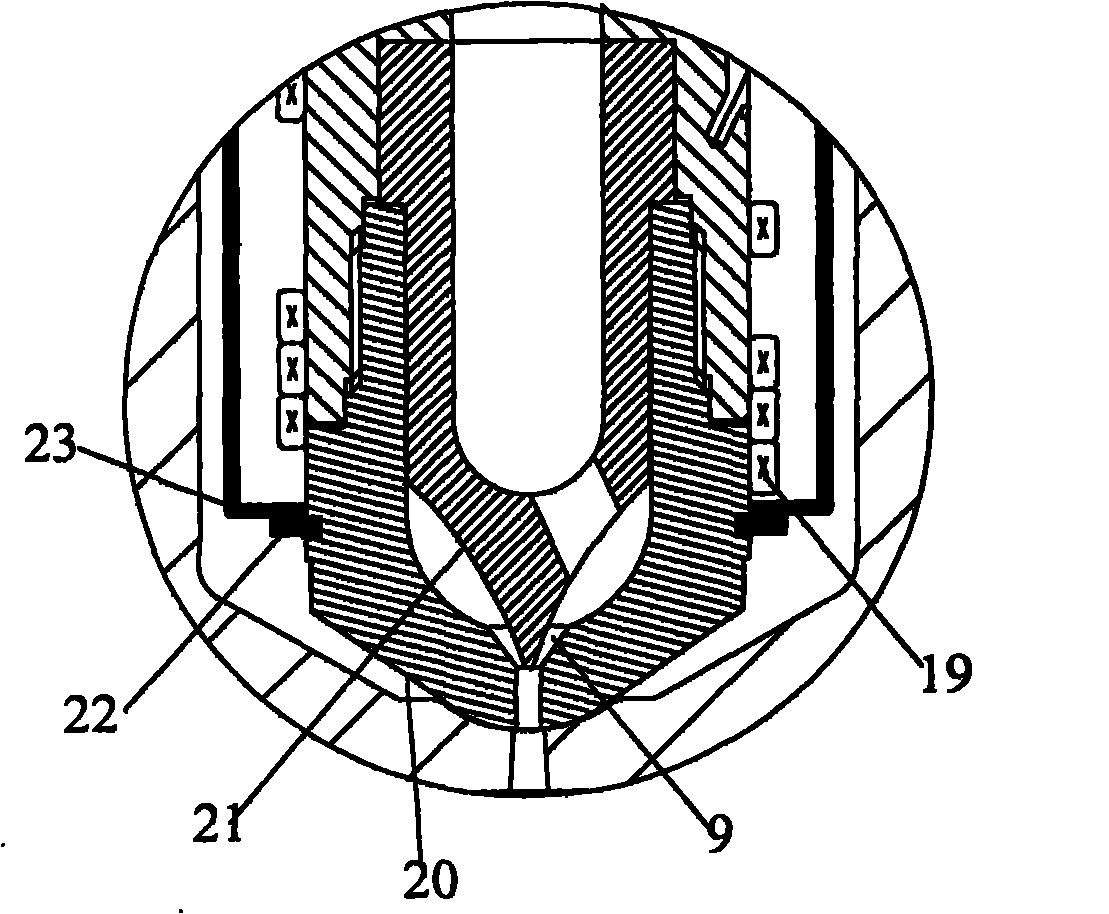

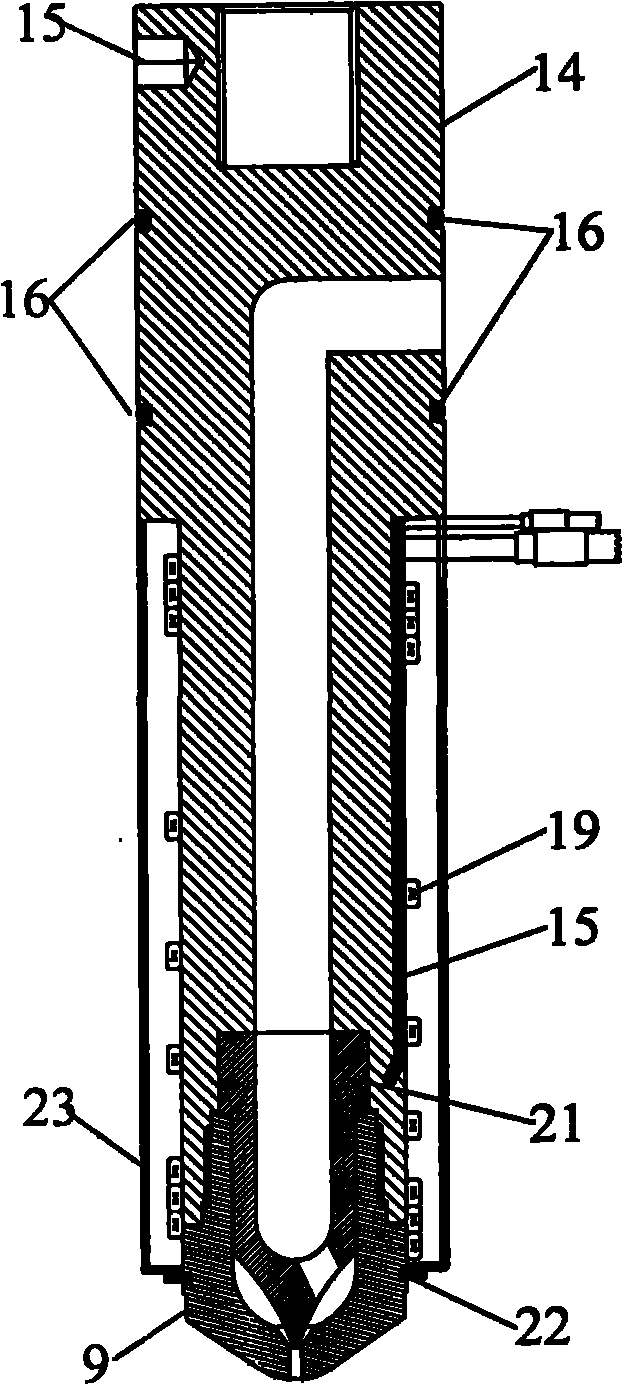

[0024] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides an embodiment of a telescopic hot runner system.

[0025] The telescopic hot runner system includes: a hot nozzle body 14, a hot runner plate 6, a main nozzle 10 and a driving device 13 connected to the hot nozzle body 14, wherein the hot runner hole on the hot nozzle body 14 140 communicates with one end of the hole 60 on the hot runner plate 6, and the other end of the hole 60 communicates with the through hole 100 on the main nozzle 10; the nozzle body 14 is provided with a first heating ring 19, a nozzle tip 21 and a heater Nozzle gate department 20, the hot nozzle gate department 20 is fixed with the hot nozzle tip 21 and the hot nozzle body 14; the hot runner plate 6 is provided with a heat pipe 5, and a There is a support ring 18 ; the second heating ring 11 is wound around the outside of the main nozzle 10 .

[0026] Specifically, the driving device 13 includes a pneumatic dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com